Abstract

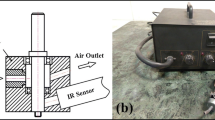

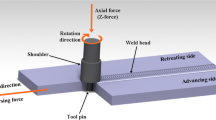

The use of friction stir welding (FSW) to join thermoplastics has proven to produce strong welds with good surface quality when compared to conventional welding methods. In this study, a Teflon stationary shoulder was developed to weld 3-mm-thick plates of high molecular weight polyethylene in butt-joint configuration. Different sets of welding parameters were chosen and tested to evaluate their effect on the weld strength. Also, in order to increase joint performance, the temperature generated during welding was measured. For that purpose, thermocouples were located underneath of the weld nugget surface to measure the generated frictional heat for different tool diameters and parameters. Tool diameter and rotational and welding speeds are the most influential parameters regarding the welding temperature; however, all the input parameters had statistically significant effect on the weld quality. Unlike FSW in metals, using this tool, the heat is generated mainly by surface contact of the rotating probe and copper sleeve than the base material. The strongest welded joint was able to withstand 97% of the force that is necessary to fracture the base material, without using an external heating source.

Similar content being viewed by others

References

Colligan KJ (2010) 2 - The friction stir welding process: an overview. Friction Stir Welding:15–41. https://doi.org/10.1533/9781845697716.1.15

Eslami S et al (2015) Effect of friction stir welding parameters with newly developed tool for lap joint of dissimilar polymers. Procedia Eng 114:199–207. https://doi.org/10.1016/j.proeng.2015.08.059

Eslami S, Tavares PJ, Moreira PMGP (2016) Friction stir welding tooling for polymers: review and prospects. Int J Adv Manuf Technol:1–14. https://doi.org/10.1007/s00170-016-9205-0

Eslami S et al (2018) Multi-axis force measurements of polymer friction stir welding. J Mater Process Technol 256:51–56. https://doi.org/10.1016/j.jmatprotec.2018.01.044

Mishra RS, Ma ZY (2005) Friction stir welding and processing. Mater Sci Eng R Rep 50:1–78. https://doi.org/10.1016/j.mser.2005.07.001

Eslami S et al (2015) Shoulder design developments for FSW lap joints of dissimilar polymers. J Manuf Process 20(Part 1):15–23. https://doi.org/10.1016/j.jmapro.2015.09.013

Besharati Givi MK, Asadi P (2014) 1 - General introduction. Adv Friction-Stir Weld Process:1–19. https://doi.org/10.1533/9780857094551.1

Thomas WM, Nicholas ED (1997) Friction stir welding for the transportation industries. Mater Des 18:269–273. https://doi.org/10.1016/S0261-3069(97)00062-9

Defalco J (2009) Friction stir process now welds steel pipe. Weld J 88:44–48

Nunes A (1998) Heat input and temperature distribution in friction stir welding. Month:163–172

Chao YJ, Qi X, Tang W (2003) Heat transfer in friction stir welding-experimental and numerical studies. J Manuf Sci Eng 125:138–145. https://doi.org/10.1115/1.1537741

Magalhães A (2016) Thermo-electric temperature measurements in friction stir welding: towards feedback control of temperature. University West

Golezani AS et al (2015) Elucidating of tool rotational speed in friction stir welding of 7020-T6 aluminum alloy. Int J Adv Manuf Technol 81:1155–1164. https://doi.org/10.1007/s00170-015-7252-6

Bozkurt Y (2012) The optimization of friction stir welding process parameters to achieve maximum tensile strength in polyethylene sheets. Mater Des 35:440–445. https://doi.org/10.1016/j.matdes.2011.09.008

Eslami S et al (2017) Parameter optimisation of friction stir welded dissimilar polymers joints. Int J Adv Manuf Technol:1–12. https://doi.org/10.1007/s00170-017-0043-5

Miranda JFC (2017) Nova ligação por FSW de materiais poliméricos

D638, A.S (2010) Standard test method for tensile properties of plastics. ASTM International. https://doi.org/10.1520/d0638-14

Gao J et al (2015) Improvements of mechanical properties in dissimilar joints of HDPE and ABS via carbon nanotubes during friction stir welding process. Mater Des 86:289–296. https://doi.org/10.1016/j.matdes.2015.07.095

Strand S (2003) Joining plastics-can friction stir welding compete? Electrical Insulation Conference and Electrical Manufacturing & Coil Winding Technology Conference, 2003. Proceedings. 321–326

Funding

Dr. Moreira acknowledges POPH – QREN-Tipologia 4.2 – Promotion of scientific employment funded by the ESF and MCTES. Authors gratefully acknowledge the funding of Project NORTE-01-0145-FEDER-000022 - SciTech - Science and Technology for Competitive and Sustainable Industries, cofinanced by Programa Operacional Regional do Norte (NORTE2020), through Fundo Europeu de Desenvolvimento Regional (FEDER). The funding provided by project Sold&Maq - Equipamento integrado de soldadura em estado sólido multimateriais e maquinagem NORTE-01-0247-FEDER-023694 is acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Eslami, S., Francisco Miranda, J., Mourão, L. et al. Polyethylene friction stir welding parameter optimization and temperature characterization. Int J Adv Manuf Technol 99, 127–136 (2018). https://doi.org/10.1007/s00170-018-2504-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-2504-x