Abstract

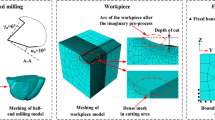

This paper presents an instantaneous cutting force prediction model for a disc mill cutter with indexable inserts. Cutting characteristics, including the normal friction angles, normal shear angles, and shear stress, are decisive factors in determining the instantaneous cutting force coefficients. The cutting characteristics can be determined by several specialized milling experiments, instead of the numerous orthogonal turning experiments that are traditionally used. In this study, the normal friction angles, normal shear angles, and shear stress are determined by a coordinate transformation of the cutting forces and the geometrical parameters of oblique cutting. Then, experiments were used to verify the cutting forces model. The results clearly indicate that shear stress can be described by a constant, nevertheless distributive law of normal shear angle and friction angle fit exponential functions of instantaneous uncut chip thickness. In conclusion, the presented model was found to successfully and accurately forecast the cutting forces of the disc mill cutter with indexable inserts under various machining conditions.

Similar content being viewed by others

References

Ren JX, Yao CF, Zhang DH, Xue YL, Liang YS (2009) Research on tool path planning method of four-axis high-efficiency slot plunge milling for open blisk. Int J Adv Manuf Technol 45(1–2):101–109. https://doi.org/10.1007/s00170-009-2153-1

Zhao P, Shi Y (2014) Adaptive sliding mode control of the A-axis used for blisk manufacturing. Chin J Aeronaut 27(3):708–715 https://www.sciencedirect.com/science/article/pii/S1000936114000831

Martellotti ME (1941) An analysis of the milling process. Trans ASME 63(8):677–700 https://www.mendeley.com/research-papers/analysis-milling-process/

Koenigsberger F, Sabberwal AJP (1961) An investigation into the cutting force pulsations during milling operations. Int J Mach Tool Des Res 1(1–2):15–33 https://www.sciencedirect.com/science/article/pii/0020735761900415

Endres WJ, DeVor RE, Kapoor SG (1995) A dual-mechanism approach to the prediction of machining forces, part 1: model development. J Eng Ind 117(4):526–533 http://manufacturingscience.asmedigitalcollection.asme.org/article.aspx?articleid=1448055

Wan M, Lu MS, Zhang WH, Yang Y (2012) A new ternary-mechanism model for the prediction of cutting forces in flat end milling. Int J Mach Tools Manuf 57:34–45 https://www.sciencedirect.com/science/article/pii/S0890695512000272

Kline WA, DeVor RE, Lindberg JR (1982) The prediction of cutting forces in end milling with application to cornering cuts. Int J Mach Tool Des Res 22(1):7–22 https://www.sciencedirect.com/science/article/pii/0020735782900166

Shi HM, Tobias SA (1984) Theory of finite amplitude machine tool instability. Int J Mach Tool Des Res 24(1):45–69 https://www.sciencedirect.com/science/article/pii/0020735784900453

Altintas Y, Spence A, Tlusty J (1991) End milling force algorithms for CAD systems. CIRP Ann Manuf Technol 40(1):31–34 https://www.sciencedirect.com/science/article/pii/S0007850607619271

Shin YC, Waters AJ (1997) A new procedure to determine instantaneous cutting force coefficients for machining force prediction. Int J Mach Tool Manu 37(9):1337–1351 https://www.sciencedirect.com/science/article/pii/S0890695596000934

Cheng PJ, Tsay JT, Lin SC (1997) A study on instantaneous cutting force coefficients in face milling. Int J Mach Tool Manu 37(10):1393–1408 https://www.sciencedirect.com/science/article/pii/S0890695597000047

Endres SN, Melkotew J (1998) The importance of including size effect when modeling slot milling. Int J Mech Sci Eng 120(1):68–75 http://manufacturingscience.asmedigitalcollection.asme.org/article.aspx?articleid=1433822

Yun WS, Cho DW (2001) Accurate 3-D cutting force prediction using cutting condition independent coefficients in end milling. Int J Mach Tools Manuf 41(4):463–478 https://www.sciencedirect.com/science/article/pii/S0890695500000973

Ko JH, Yun WS, Cho DW, Ehmann KF (2002) Development of a virtual machining system, part 1: approximation of the size effect for cutting force prediction. Int J Mach Tools Manuf 42(15):1595–1605 https://www.sciencedirect.com/science/article/pii/S0890695502001372

Ko JH, Cho DW (2005) 3D ball-end milling force model using instantaneous cutting force coefficients. J Manuf Sci Eng 127(1):1–12 http://manufacturingscience.asmedigitalcollection.asme.org/article.aspx?articleid=1449404

Wan M, Zhang WH, Qin GH, Tan G (2007) Efficient calibration of instantaneous cutting force coefficients and runout parameters for general end mills. Int J Mach Tools Manuf 47(11):1767–1776 http://www.sciencedirect.com/science/article/pii/S0890695506001660

Dang JW, Zhang WH, Yang Y, Wan M (2010) Cutting force modeling for flat end milling including bottom edge cutting effect. Int J Mach Tools Manuf 50(11):986–997 https://www.sciencedirect.com/science/article/pii/S0890695510001380

Wan M, Pan WJ, Zhang WH, Ma YC, Yang Y (2014) A unified instantaneous cutting force model for flat end mills with variable geometries. J Mater Process Technol 214(3):641–650 https://www.sciencedirect.com/science/article/pii/S0924013613003233

Hao H, Wang B, Tang W (2015) Prediction of instantaneous milling force taking runout into account in peripheral milling of curved surface. Int J Adv Manuf Technol 79(1–4):49–56. https://doi.org/10.1007/s00170-015-6803-1

Jia ZY, Ge J, Ma JW, Gao YY, Liu Z (2016) A new cutting force prediction method in ball-end milling based on material properties for difficult-to-machine materials. Int J Adv Manuf Technol 86(9–12):1–16. https://doi.org/10.1007/s00170-016-8351-8

Zhang Z, Li H, Meng G, Ren S, Zhou J (2017) A new procedure for the prediction of the cutting forces in peripheral milling. Int J Adv Manuf Technol 89:1709–1715. https://doi.org/10.1007/s00170-016-9186-z

Svahn M, Andersson C, Vedmar L (2016) Prediction and experimental verification of the cutting forces in gear form milling. Int J Adv Manuf Technol 82(1–4):111–121. https://doi.org/10.1007/s00170-015-7309-6

Kline WA, Devor RE (1983) The effect of runout on cutting geometry and forces in end milling. Int J Mach Tool Des Res 23(2):123–140 https://www.sciencedirect.com/science/article/pii/0020735783900124

Wan M, Lu MS, Zhang WH, Yang Y, Li Y (2012) A new method for identifying the cutter runout parameters in flat end milling process. Mater Sci Forum 697:71–74 https://www.scientific.net/MSF.697-698.71

Altintas Y (2000) Manufacturing automation: metal cutting mechanics, machine tool vibrations, and CNC design. Cambridge University Press

Stabler GV (1964) The chip flow law and its consequences. Adv Mach Tool Des Res 5:243–251 https://www.researchgate.net/publication/303802426_The_chip_flow_law_and_its_consequences

Funding

This paper was supported by the National Science and Technology Major Project of China (grant no. 2013ZX04001-081).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, N., Shi, Y., Yang, C. et al. An instantaneous cutting force model for disc mill cutter based on the machining blisk-tunnel of aero-engine. Int J Adv Manuf Technol 99, 233–246 (2018). https://doi.org/10.1007/s00170-018-2434-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-2434-7