Abstract

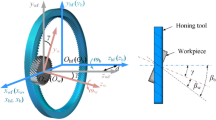

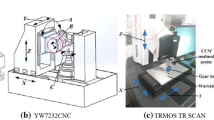

In order to understand the formation mechanism of surface arc texture of internal gear power honing, the contact line equation of tooth surface is derived with homogeneous coordinate transformation method, which is based on the involute helical tooth surface equation of honed workpiece gear as well as the meshing principle of space surface. Then the influence of shaft angle Σ on the formation of surface arc texture of workpiece is analyzed. The results of imager and three-dimensional (3D) profilometer are in accordance with the theoretical derivation. In order to analyze the influence of the power honing process parameters on the surface roughness, a central composite surface design method based on response surface methodology (RSM) is proposed in a range of process parameters. Based on this, a regression model of surface roughness for the honed workpiece gear is established. Meanwhile, the influence of power honing process parameters on the surface roughness of honed workpiece gear is analyzed. The process parameters are the honing wheel speed nH, Z feed fZ, and X feed fX. The three-dimensional profilometer is utilized to analyze the roughness value with a set of process parameters, based on which the accuracy and reliability of the model can be verified. The results show that the surface arc texture is suitable for producing dense textures when the shaft angle Σ is within 5° to 10°. According to the analysis, nH has the greatest influence on the surface roughness of the honed workpiece gear. The effects of fZ and fX are almost the same when Ra ≥ 0.4 μm, and while Ra ≤ 0.3 μm, the effect of fZ is slightly higher than that of fX, Ra is the regression value obtained after the honing process. Based on the mention above, the surface quality of the honed workpiece gear can be predicted and controlled before honing.

Similar content being viewed by others

References

Hu DH, Zhang L, Guo GL, Wang PJ (2016) Tool presetting method for grinding based on the worst angles of tooth space edges. Int J Adv Manuf Technol 82(5):921–926

Aloso U, Ortega N, Sanchez JA, Pombo I, Plaza S, Izquierdo B (2014) In-process prediction of the hardened layer in cylindrical traverse grind-hardening. Int J Adv Manuf Technol 71(1):101–108

Hu YJ, Wang YQ, Zhao GL, Wang Y, Yuan XH (2011) Feature-based modeling of automobile gears and maufactureing resources for virtual manufacturing. Int J Adv Manuf Technol 55(1):405–419

Brecher C, Brumm M, Hübner F (2015) Approach for the calculation of cutting forces in generating gear grinding. Procedia CIRP 33:287–292

Sandro PS, Lincoln CB, Luis HG, de Zelda CS (2012) Finishing process analysis between honing and hard hobbing in pinion gears applied to a steering system. Energy Procedia 14(2012):2–8

Silva SP, Brandao LC, Rafael FPP (2011) Evaluation of quality of steering systems using the honing process and surface response methodology. Adv Mater Res 223:821–825

Bouzakis KD (2008) Manufacturing of cylindrical gears by generating cutting processes: A critical synthesis of analysis methods. CIRP Annals 57(2):676–696

L.C Brandão, S P Silva, GA Abreu, PC Lima (2009) O processo de acabamento em pinhões de sistemas de direção. In: COBEF-Congresso Brasileiro de Engenharia de Fabricação. pp 11–20

Amini N, Westberg H, Klocke F (1999) An experimental study on the effect of power honing on gear surface topography. Gear Technol 16(1):11–18

Jolivet S, Mezghani S, Issenlin J, Mansori EI (2016) Numerical simulation of tooth surface finish effects on gear noise. Appl Scien Technol Sour 102:436–443

Jolivet S, Mezghani S, Mansori EM, Jourdain B (2015) Dependence of tooth flank finishing on powertrain gear noise. J Manuf Syst 37(42):467–471

Denkena B, Schindler A, Woiwode S (2016) Calculation method of the contact area in flank machining for continuous generating grinding. Appl Math Model 40(15–16):7138–7146

Chakrabarti S, Paul S (2008) Numerical modeling of surface topography in super-abrasive grinding. Int J Adv Manuf Technol 39(1):29–38

Nguyen TA, Butler DL (2005) Simulation of precision grinding process, Part1: generation of the grinding wheel surface. Int J Mach Tools Manuf 45(11):1321–1328

Hecker RL, Liang SY (2003) Predictive modeling of surface roughness in grinding. Int J Mach Tools Manuf 43(8):755–761

Stepien P (2009) A probabilistic model of the grinding process. Appl Math Model 33(10):3863–3884

Thyssen W (2006) Erfahrungen und visionen mit der CNC-Hochleistungs-Schleifmaschine RZ 150/RZ 400 HEUTE und in ZUKUNFT, Presentation Company Reishauer, Wallisellen. (CH)

Karpuschewski B, Knoche HJ, Hipke M (2008) Gear finishing by abrasive process. CIRP Ann Manuf Technol 57:620–640

Chen ST, Hu HF, Zhang C (2015) Surface roughness modeling based on laser speckle imaging. Acta Phys Sin 64(23):234203

Ho WH, Tsai JT, Lin BT, Zhou JH (2009) Adaptive network based fuzzy inference system for prediction of surface roughness in end milling process using hybrid Taguchi-genetic learning algorithm. Expert Syst Appl 36(2):3216–3222

Thomas TR (1982) Rough surface. Longman, London

Whitehouse DJ (1994) Handbook of surface metrology. Bristol, UK: Institute of Physics

Tsai YS, Chen JC, Lou SJ (1999) An in-process surface recognition system based on neural networks in end milling cutting operations. Int J Mach Tools Manuf 39(4):583–605

Suykens JAK, Vandewalle J (1999) Least squares support vector machine classifiers. Neural Process Lett 9(3):293–300

Caydas U, Ekici S (2012) Support vector machines models for surface roughness prediction in CNC turning of AISI 304 austenitic stainless steel. J Intell Manuf 23(3):639–650

Sandro S, Moni RF, Lincoln CB (2014) Particle swarm optimization for achieving the minimum profile error in honing process. Pre Eng J Int Societ Pre Eng Nanotechnol 38(4):759–768

Sayles RS, Thomas TR (1978) Surfaces topography as a non- stationary random process. Nature 27(1):431–434

Litvin FL, Fuentes A (2004) Gear geometry and applied theory, second edn. Cambridge University Press, New York

Thirugnanasambandham K, Sivakumar V (2015) Optimization of treatment of grey wastewater using electroFenton technique-modeling and validation. Process Saf Environ Prot 95:60–68

Funding

This study is mainly funded by the National Natural Science Foundation of China (Grant No.51575154), and the Major National R&D Projects (Grant No.2013ZX 04002051).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Han, J., Zhang, G. Investigation on formation mechanism of surface texture and modeling of surface roughness with internal gear power honing. Int J Adv Manuf Technol 98, 603–615 (2018). https://doi.org/10.1007/s00170-018-2265-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-2265-6