Abstract

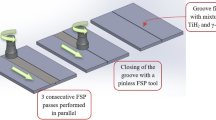

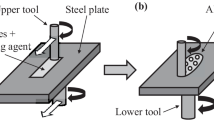

The aim of the present research is the fabrication of MWCNT-reinforced Al composite foams on localized regions of metallic parts using a novel friction stir processing (FSP) route. This route consists of friction stir processing passes for the integration of the foaming and the stabilizing agents in the aluminum matrix (precursor specimens) and a separate foaming stage at a laboratory furnace. The precursor specimens were manufactured by mixing a blowing agent powder (0.4% w/w TiH2) and a stabilization agent nanopowder (2% w/w MWCNT) into the aluminum alloy matrix (AA5083-H111), using the intense stirring action of FSP. The porous aluminum obtained at the foaming stage has a medium porosity of 54% with a high circularity of pores. The microstructural investigation was performed by means of optical microscopy (OM), scanning electron microscopy (SEM), and electron backscatter diffraction (EBSD) technique. All of the above were correlated with microhardness distribution in both the precursor and the foamed specimens. The microstructure was found to be closely related to microhardness distribution perpendicular to the traversing direction of the FSP tool for both precursor and foamed specimens.

Similar content being viewed by others

References

Gibson LG, Ashby MF (1997) Cellular solids, structure and properties, 2nd edn. Cambridge University Press, Cambridge

Ashby MF, Evans AG, Fleck NA, Gibson LJ, Hutchinson JW, Wadley HNG (2000) Metal foams: a design guide. Butterworth-Heinemann, USA

Tzeng SC, Ma WP (2006) A novel approach to manufacturing and experimental investigation of closed-cell Al foams. Int J Adv Manuf Technol 28:1122–1128

Gama BA, Bogetti TA, Fink BK, Yue CJ, Claar DT, Eiferte HH, Gillespie JW (2001) Aluminum foam integral armor: a new dimension in armor design. Compos Struct 52:381–395

Banhart J (2001) Manufacture, characterization and application of cellular metals and metal foams. Prog Mater Sci 46:559–632

Mouritz AP, Gellert E, Burchill P, Challis K (2001) Review of advanced composite structures for naval ships and submarines. Compos Struct 53:21–42

Mishra RS, Ma ZY (2005) Friction stir welding and processing. Mater Sci Eng R 50:1–78

Ma ZY (2008) Friction stir processing technology: a review. Metall Mater Trans 39A:642–658

Pantelis DI, Karakizis PN, Daniolos NM, Alexandratos SA, Papantoniou IG (2014) Study of Al2O3-Aluminum matrix composites fabrication using friction stir processing technique, Proceedings of the 11th International Conference “THE-A” 309–318

Shojaeefard MH, Akbari M, Asadi P, Khalkhali A (2017) The effect of reinforcement type on the microstructure, mechanical properties, and wear resistance of A356 matrix composites produced by FSP. Int J Adv Manuf Technol 91:1391–1407

Sadeghi B, Shamanian M, Cavaliere P et al. (2017) Microstructural and mechanical behavior of bimodal reinforced Al-based composites produced by spark plasma sintering and FSP, Int J Adv Manuf Technol 1–14

Zang Z, Zeng X, Du J, Wang M, Tang X (2016) Femtosecond laser direct writing of microholes on roughened ZnO for output power enhancement of InGaN light-emitting diodes. Opt Lett 41:3463–3466

Pantelis DI, Karakizis PN, Daniolos NM, Charitidis CA, Koumoulos EP, Dragatogiannis DA (2016) Microstructural study and mechanical properties of dissimilar friction stir welded AA5083-H111 and AA6082-T6 reinforced with SiC nanoparticles. Mater Manuf Process 31:264–274

Hangai Y, Utsunomiya T (2009) Fabrication of porous aluminum by friction stir processing. Metall Mater Trans 40A:275–277

Hangai Y, Utsunomiya T, Hasegawa M (2010) Effect of tool rotating rate on foaming properties of porous aluminum fabricated by using friction stir processing. J Mater Process Technol 210:288–292

Utsunomiya T, Tamura K, Hangai Y, Kuwazuru O, Yoshikawa N (2010) Effects of tool rotating rate and pass number on pore structure of A6061 porous aluminum fabricated by using friction stir processing. Mater Trans 51:542–547

Saito K, Hangai Y, Utsunomiya T, Kuwazuru O, Yoshikawa N (2014) Fabrication and compression properties of functionally graded foam with uniform pore structures consisting of dissimilar A1050 and A6061 aluminum alloys. Mater Sci Eng A 613:163–170

Storjohann D, Barabash OM, David SA, Sklad PS, Bloom EE, Babu SS (2005) Fusion and friction stir welding of aluminium metal matrix composites. Metall Mater Trans 36A:3237–3247

Asadi P, Besharati Givi MK, Akbari M (2016) Simulation of dynamic recrystallization process during friction stir welding of AZ91 magnesium alloy. Int J Adv Manuf Technol 83:301–311

Etter AL, Baudin T, Fredj N, Penelle R (2007) Recrystallization mechanisms in 5251 H14 and 5251O aluminum friction stir welds. Mater Sci Eng 445A:94–99

Humphreys J, Hatherly M (2004) Recrystallization and related annealing phenomena. Elsevier Science, Oxford

Huang K, Logé RE (2016) A review of dynamic recrystallization phenomena in metallic materials. Mater Des 1115:48–574

Hallberg H, Wallin M, Ristinmaa M (2010) Modeling of continuous dynamic recrystallization in commercial-purity aluminum. Mater Sci Eng A 527:1126–1134

Zhang Z, Chen DL (2008) Contribution of Orowan strengthening effect in particulate reinforced metal matrix nanocomposites. Mater Sci Eng A 483-484:148–152

Prater T (2014) Friction stir welding of metal matrix composites for use in aerospace structures. Acta Astronaut 93:366–373

Kunming Y, Xudong Y, Enzuo L, Chunsheng S, Liying M, Chunnian H, Qunying L, Jiajun L, Naiqin Z (2017) Elevated temperature compressive properties and energy absorption response of in-situ grown CNT-reinforced Al composite foams. Mater Sci Eng A 690:294–302

Wang J, Yang X, Zhang M, Li J, Shi C, Zhao N, Zou T (2015) A novel approach to obtain in-situ growth carbon nanotube reinforced aluminum foams with enhanced properties. Mater Lett 161:763–766

Jiang B, Zhao NQ, Shi CS, Li JJ (2005) Processing of open cell aluminum foams with tailored porous morphology. Scr Mater 53:781–785

Raj SV (2011) Microstructural characterization of metal foams: an examination of the applicability of the theoretical models for modeling foams. Mater Sci Eng A 528:5289–5295

Bock J, Jacobi AM (2013) Geometric classification of open-cell metal foams using X-ray micro-computed tomography. Mater Charact 75:35–43

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Papantoniou, I.G., Kyriakopoulou, H.P., Pantelis, D.I. et al. Fabrication of MWCNT-reinforced Al composite local foams using friction stir processing route. Int J Adv Manuf Technol 97, 675–686 (2018). https://doi.org/10.1007/s00170-018-1964-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-1964-3