Abstract

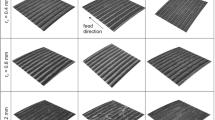

Despite excellent mechanical and physical features of titanium metal matrix composite (Ti-MMC), hard and abrasive ceramic particles within the matrix structure, as well as high price, may lead to severe difficulties on machining and machinability of Ti-MMCs. Review of literature denotes that only limited studies are available on machining Ti-MMCs with commercial cutting tools under various cutting conditions and cutting tools/inserts. Furthermore, limited studies are available on machinability attributes of Ti-MMC under various cutting conditions used. Therefore, to remedy the lack of knowledge observed, this work intends to report turning Ti-MMCs with carbide, and cubic boron nitride (CBN) inserts under various cutting conditions. The mean values of surface roughness (Ra) and directional cutting forces, as well as flank wear (VB) were studied as the machinability attributes. The microstructural evaluations were conducted to discover the wear modes. Furthermore, the statistical tools were used to present the factors governing machining attributes studied. Adhesion, abrasion, and oxidation were observed as the principle wear modes on the flank sides of the tested inserts. According to experimental results and statistical analysis, the Ra and VB could be controlled by cutting parameters only when CBN inserts were used. Despite the inset used, factors governing both responses were not identical. Although average cutting forces were directly affected by cutting parameters used, however, the relatively low correlation of determination (R2) of directional cutting forces can be attributed to effects of cutting speed, elevated temperature in the cutting zone as well as rapid tool wear which are all correlated to others.

Similar content being viewed by others

References

Lee W, Lin C (1997) Adiabatic shear fracture of titanium alloy subjected to high strain rate and high temperature loadings. Le Journal de Physique IV 7:C3–855–C3–860

Niknam SA, Khettabi R, Songmene V (2014) "Machinability and machining of titanium alloys: a review," in Machining of titanium alloys, ed: Springer Berlin Heidelberg, pp. 1–30

Zhang X, Shivpuri R, Srivastava A (2017) A new microstructure-sensitive flow stress model for the high-speed machining of titanium alloy Ti–6Al–4V. J Manuf Sci Eng 139:051006

Liu D, Wang F, Liu R-Y 2017 "Experimental study on the serrated Chip while machining titanium alloy," DEStech Trans Eng Technol Res

Jackson MJ, Novakov T, Whitfield M, Robinson G, Handy R, Sein H, Ahmed W (2017) VFCVD diamond-coated cutting tools for micro-machining titanium alloy Ti6Al4V. Int J Adv Manuf Technol 92:1–38

Nath C, Kapoor SG, Srivastava AK, Iverson J (2014) Study of droplet spray behavior of an atomization-based cutting fluid spray system for machining titanium alloys. J Manuf Sci Eng 136:021004

Shams O, Pramanik A, Chandratilleke T (2017) "Thermal-assisted machining of titanium alloys," in Advanced Manufacturing Technologies, ed: Springer, pp. 49–76

Liu D, Liu R-Y, Wang F 2017 "Simulation of cutting temperature distribution while machining titanium alloy TC4," DEStech Trans Eng Technol Res

Davim JP, Baptista AM (2000) Relationship between cutting force and PCD cutting tool wear in machining silicon carbide reinforced aluminium. J Mater Process Technol 103:417–423

Davim J, Monteiro Baptista A (2001) Cutting force, tool wear and surface finish in drilling metal matrix composites. Proc Inst Mech Eng E J Process Mech Eng 215:177–183

Davim JP, Antonio CC (2001) Optimal drilling of particulate metal matrix composites based on experimental and numerical procedures. Int J Mach Tools Manuf 41:21–31

Davim JP (2003) Study of drilling metal–matrix composites based on the Taguchi techniques. J Mater Process Technol 132:250–254

Davim J, Sreejith P, Gomes R, Peixoto C (2006) Experimental studies on drilling of aluminium (AA1050) under dry, minimum quantity of lubricant, and flood-lubricated conditions. Proc Inst Mech Eng B J Eng Manuf 220:1605–1611

Davim JP (2008) Machining: fundamentals and recent advances: Springer Science & Business Media

Bains PS, Sidhu SS, Payal H (2016) Fabrication and machining of metal matrix composites: a review. Mater Manuf Process 31:553–573

Singh Bains P, Sidhu SS, Payal H (2016) Study of magnetic field-assisted ED machining of metal matrix composites. Mater Manuf Process 31:1889–1894

Nicholls CJ, Boswell B, Davies IJ, Islam MN (2017) Review of machining metal matrix composites. Int J Adv Manuf Technol 90:2429–2441

Aramesh M, Attia HM, Kishawy HA, Balazinski M (2017) "Observation of a unique wear morphology of cBN inserts during machining of titanium metal matrix composites (Ti-MMCs); leading to new insights into their machinability," Int J Adv Manuf Technol, pp. 1–12

Kamali Zadeh S (2016) "Initial tool wear mechanisms in turning of titanium metal matrix composites," École Polytechnique de Montréal

Bejjani R, Balazinski M, Attia H, Plamondon P, L’Éspérance G (2016) Chip formation and microstructure evolution in the adiabatic shear band when machining titanium metal matrix composites. Int J Mach Tools Manuf 109:137–146

Aramesh M (2015) "Machinability of titanium metal matrix composites (Ti-MMCs)," École Polytechnique de Montréal

Asgari A (2015) "Cutting conditions optimisation of titanium metal matrix composites in turning and face milling," École Polytechnique de Montréal

Bejjani R (2012) "Machinability and modeling of cutting mechanism for titanium metal matrix composites," École Polytechnique de Montréal

Bejjani R, Balazinski M, Shi B, Attia H, Kishawy H (2011) "Machinability and chip formation of titanium metal matrix composites," Int J Adv Manuf Syst IJAMS, vol 13

Bejjani R, Shi B, Attia H, Balazinski M (2011) Laser assisted turning of titanium metal matrix composite. CIRP Ann Manuf Technol 60:61–64

Zhu D, Zhang X, Ding H (2013) Tool wear characteristics in machining of nickel-based superalloys. Int J Mach Tools Manuf 64:60–77

Konig W 1978 "applied research on the machinability of titanium and its alloys," in Proc. AGARD Conf. Advanced Fabrication Processes, Florence, p. 1979

Davim JP (2012) Tribology in manufacturing technology: springer

Jin L, Riahi A, Farokhzadeh K, Edrisy A (2014) Investigation on interfacial adhesion of Ti–6Al–4V/nitride coatings. Surf Coat Technol 260:155–167

Kwon P (2000) Predictive models for flank wear on coated inserts. ASME J Tribol 122:340–347

Islam C, Lazoglu I, Altintas Y (2016) A three-dimensional transient thermal model for machining. J Manuf Sci Eng 138:021003

Kumar S, Singh R, Batish A, Singh T (2017) Modeling the tool wear rate in powder mixed electro-discharge machining of titanium alloys using dimensional analysis of cryogenically treated electrodes and workpiece. Proc Inst Mech Eng E J Process Mech Eng 231:271–282

Hung N, Venkatesh V, Loh N 1998 "Cutting tools for metal matrix composites," in Key engineering materials, pp. 289–326

Klimczyk P, Figiel P, Petrusha I, Olszyna A (2011) Cubic boron nitride based composites for cutting applications. J Achiev Mater Manuf Eng 44:198–204

Phadke MS (1989) Quality engineering using robust design. Prentice Hall, Englewood Cliffs

Hosseini A, Kishawy HA (2014) "Cutting tool materials and tool wear," in Machining of Titanium Alloys, ed: Springer, pp. 31–56

Sadat AB (2012) "Surface integrity when machining metal matrix composites," in Machining of metal matrix composites, ed: Springer, , pp. 51–61

Übeylı M, Acir A, Serdar Karakaş M, Ögel B (2008) Effect of feed rate on tool wear in milling of Al-4% cu/B4 C p composite. Mater Manuf Process 23:865–870

Soo S, Aspinwall D, Dewes R (2004) 3D FE modelling of the cutting of Inconel 718. J Mater Process Technol 150:116–123

Khan M, Mithu M, Dhar NR (2009) Effects of minimum quantity lubrication on turning AISI 9310 alloy steel using vegetable oil-based cutting fluid. J Mater Process Technol 209:5573–5583

Tazehkandi AH, Pilehvarian F, Davoodi B (2014) Experimental investigation on removing cutting fluid from turning of Inconel 725 with coated carbide tools. J Clean Prod 80:271–281

Davoodi B, Hosseini Tazehkandi A (2016) Cutting forces and surface roughness in wet machining of Inconel alloy 738 with coated carbide tool. Proc Inst Mech Eng B J Eng Manuf 230:215–226

Honghua S, Peng L, Yucan F, Jiuhua X (2012) Tool life and surface integrity in high-speed milling of titanium alloy TA15 with PCD/PCBN tools. Chin J Aeronaut 25:784–790

Froes F, Friedrich H, Kiese J, Bergoint D (2004) Titanium in the family automobile: the cost challenge. JOM J Miner Met Mater Soc 56:40–44

Bindal M, Singhal S, Singh B, Nayar R, Chopra R, Dhar A (1991) Synthesis of cubic boron nitride using magnesium as the catalyst. J Cryst Growth 112:386–401

Acknowledgments

The financial support received from Fonds Québécois de la Recherche sur la Nature et les Technologies (FQRNT) and NSERC Canadian Network for Research and Innovation in Machining Technology (CANRIMT) are highly appreciated.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Niknam, S.A., Kamalizadeh, S., Asgari, A. et al. Turning titanium metal matrix composites (Ti-MMCs) with carbide and CBN inserts. Int J Adv Manuf Technol 97, 253–265 (2018). https://doi.org/10.1007/s00170-018-1926-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-1926-9