Abstract

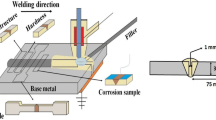

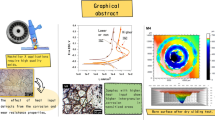

Austenitic stainless steel has excellent properties with respect to general corrosion resistance, while it is sensitive to localized corrosive attacks, such as pitting and crevice corrosion in humid and chloride-containing atmospheres. This pitting corrosion susceptibility increases when it is exposed to conditions like resistance spot welding (RSW) process. The current research deals with the effect of RSW shielding gas atmosphere on the pitting corrosion behavior of AISI 304L austenitic stainless steel weld joints. Optical and SEM investigations show several types of pit sizes and morphologies depending on heat input and shielding gas. Cyclic potentiodynamic polarization (CPP) of welded nuggets shows that argon gas is more effective in the improvement of pitting corrosion resistance at low heat input, while nitrogen demonstrates better corrosion resistance at high heat input.

Similar content being viewed by others

References

Horiuchi T, Reed RP (2012) Austenitic steels at low temperatures. Springer Science & Business Media, Berlin

Nishimoto K, Ogawa K (1999) Corrosion properties in weldments of stainless steels (1). Metallurgical factors affecting corrosion properties. Weld Int 13(11):845–854. https://doi.org/10.1080/09507119909452061

Gooch TG (1996) Corrosion behavior of welded stainless steel. Welding Journal-Including Welding Research Supplement 75(5):135s

Loto RT (2013) Pitting corrosion evaluation of austenitic stainless steel type 304 in acid chloride media. J Mater Environ Sci 4(4):448–459

Tsutsumi Y, Nishikata A, Tsuru T (2007) Pitting corrosion mechanism of Type 304 stainless steel under a droplet of chloride solutions. Corros Sci 49(3):1394–1407. https://doi.org/10.1016/j.corsci.2006.08.016

Aravinthan A, Nachimani C (2011) Analysis of spot weld growth on mild and stainless steel. Weld J 90(8):143–147

Pouranvari M, Alizadeh-Sh M, Marashi SPH (2015) Welding metallurgy of stainless steels during resistance spot welding Part I: fusion zone. Sci Technol Weld Join 20(6):502–511. https://doi.org/10.1179/1362171815Y.0000000015

Somervuori M, Johansson LS, Heinonen MH, Van Hoecke DHD, Akdut N, Hänninen HE (2004) Characterisation and corrosion of spot welds of austenitic stainless steels. Mater Corros 55(6):421–436. https://doi.org/10.1002/maco.200303753

Bayoumi FM, Ghanem WA (2005) Effect of nitrogen on the corrosion behavior of austenitic stainless steel in chloride solutions. Mater Lett 59(26):3311–3314. https://doi.org/10.1016/j.matlet.2005.05.063

Lei MK, Zhu XM (2005) Role of nitrogen in pitting corrosion resistance of a high-nitrogen face-centered-cubic phase formed on austenitic stainless steel. J Electrochem Soc 152(8):B291. https://doi.org/10.1149/1.1939245

Özyürek D (2008) An effect of weld current and weld atmosphere on the resistance spot weldability of 304L austenitic stainless steel. Mater Des 29 (3):597–603. https://doi.org/10.1016/j.matdes.2007.03.008

ASTM G5-94(2011)e1, Standard reference test method for making potentiostatic and potentiodynamic anodic polarization measurements. ASTM International, West Conshohocken, PA. https://doi.org/10.1520/G0005-94R11E01

ASTM G46-94(2013), Standard guide for examination and evaluation of pitting corrosion. ASTM International, West Conshohocken, PA. https://doi.org/10.1520/G0046

Arturo GRM, Hugo LMV, Rafael GH, Egberto BB, Antonio GSJ (2015) Electrochemical characterization of AISI 2205 duplex stainless steel welded joints with electromagnetic interaction. Procedia Materials Science 8:950–958. https://doi.org/10.1016/j.mspro.2015.04.156

Wilde BE, Williams E (1971) The use of current/voltage curves for the study of localized corrosion and passivity breakdown on stainless steels in chloride media. Electrochim Acta 16(11):1971–1985. https://doi.org/10.1016/0013-4686(71)85151-4

Wilde BE, Williams E (1970) On the correspondence between electrochemical and chemical accelerated pitting corrosion tests. J Electrochem Soc 117(6):775–779. https://doi.org/10.1149/1.2407627

Somervuori M, Johansson LS, Heinonen MH, Van Hoecke DHD, Akdut N, Hänninen HE (2004) Characterisation and corrosion of spot welds of austenitic stainless steels. Mater Corros 55(6):421–436. https://doi.org/10.1002/maco.200303753

Rao BR, Rao KP, Iyer KJL (1993) Effect of chemical composition and ferrite content on room temperature SCC behavior of austenitic weld metals. Corrosion 49(3):248–255. https://doi.org/10.5006/1.3316045

Krishnan KN, Rao KP (1991) Effect of microstructure on stress corrosion cracking behaviour of austenitic stainless steel weld metals. Mater Sci Eng A 142(1):79–85. https://doi.org/10.1016/0921-5093(91)90756-D

Lu BT, Chen ZK, Luo JL, Patchett BM, Xu ZH (2005) Pitting and stress corrosion cracking behavior in welded austenitic stainless steel. Electrochim Acta 50(6):1391–1403. https://doi.org/10.1016/j.electacta.2004.08.036

Huntz AM, Reckmann A, Haut C, Sévérac C, Herbst M, Resende FCT, Sabioni ACS (2007) Oxidation of AISI 304 and AISI 439 stainless steels. Mater Sci Eng A 447(1):266–276. https://doi.org/10.1016/j.msea.2006.10.022

Wang YQ, Li N, Yang B (2015) Effect of ferrite on pitting corrosion of Fe20Cr9Ni cast austenite stainless steel for nuclear power plant pipe. Corros Eng Sci Technol 50(4):330–337. https://doi.org/10.1179/1743278214Y.0000000229

Palit GC, Kain V, Gadiyar HS (1993) Electrochemical investigations of pitting corrosion in nitrogen-bearing type 316LN stainless steel. Corrosion 49 (12):977–991. https://doi.org/10.5006/1.3316025

Osozawa K, Okato N (1976) Effect of alloying elements, especially n, on the initiation of pitting in stainless steel. Passivity and its breakdown on iron and iron base alloys. National Association of Corrosion Engineers, Houston, pp 135–139

Di Schino A, Barteri M, Kenny JM (2003) Effects of grain size on the properties of a low nickel austenitic stainless steel. J Mater Sci 38(23):4725–4733. https://doi.org/10.1023/A:1027470917858

Kim ST, Kim SY, Lee IS, Park YS, Shin MC, Kim YS (2011) Effects of shielding gases on the microstructure and localized corrosion of tube-to-tube sheet welds of super austenitic stainless steel for seawater cooled condenser. Corros Sci 53(8):2611–2618. https://doi.org/10.1016/j.corsci.2011.04.021

Acknowledgements

The author wishes to acknowledge the support from Hail University. I would also like to thank Prof. Ibrahim M Ghayat (CMRDI), for his help and valuable discussion.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hafez, K.M. The effect of welding atmosphere on the pitting corrosion of AISI 304L resistance spot welds. Int J Adv Manuf Technol 97, 243–251 (2018). https://doi.org/10.1007/s00170-018-1915-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-1915-z