Abstract

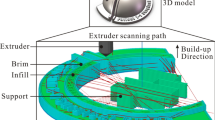

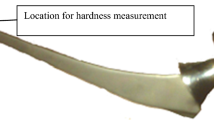

Fused deposition modelling (FDM) is a technique of additive manufacturing (AM) which is capable of fast construction of plastic prototypes. AM technology has been utilised in orthopaedics and traumatology to fabricate patient-specific models, surgical guides, and implants. However, the layering build-up by FDM usually generates a deleterious rough surface that limits its application to items such as surgical guide and surgical operating guide, because these items require a highly resolved surface quality. The advancement of laser polishing has been offering a cost-effective and fast manufacturing solution for FDM-constructed patient-specific guides and implants. This investigation explores application potential using a contactless laser scanning to improve the surface quality of FDM-fabricated thermoplastics. The results show that a maximum [68%] reduction in surface roughness was achieved at 3 W CO2 laser power, 150 mm/s scan speed, 30 ms scan delay and 0.025 mm line gap. Laser polishing is suitable to treat the surface of polylactic acid (PLA). This study provides data which supports a new approach to the manufacture of AM-fabricated thermoplastics utilising a laser scanning technique to improve the surface quality.

Similar content being viewed by others

References

Gibson I, Rosen DW, Stucker B (2010) Additive manufacturing technologies. Springer

Chai Y, Qin Q-H, Xiao Y (2016) Recent patents on construction additive manufacturing method. Recent Patents Mech Eng 9:94–101

Wohlers T (2016) Wohlers report 2016. Wohlers Associates, Inc

Gharbi M, Peyre P, Gorny C, Carin M, Morville S, Le Masson P, Carron D, Fabbro R (2014) Influence of a pulsed laser regime on surface finish induced by the direct metal deposition process on a Ti64 alloy. J Mater Process Technol 214:485–495

Gharbi M, Peyre P, Gorny C, Carin M, Morville S, Le Masson P, Carron D, Fabbro R (2013) Influence of various process conditions on surface finishes induced by the direct metal deposition laser technique on a Ti–6Al–4V alloy. J Mater Process Technol 213:791–800

Pandey PM, Reddy NV, Dhande SG (2003) Improvement of surface finish by staircase machining in fused deposition modeling. J Mater Process Technol 132:323–331

Chohan JS, Singh R (2016) Enhancing dimensional accuracy of FDM based biomedical implant replicas by statistically controlled vapor smoothing process. Prog Addit Manuf 1:105–113

Vasudevarao B, Natarajan DP, Henderson M, Razdan A (2000) Sensitivity of RP surface finish to process parameter variation. Solid Freeform Fabrication Proceedings, p 251–258

Rayegani F, Onwubolu G (2014) Fused deposition modelling (FDM) process parameter prediction and optimization using group method for data handling (GMDH) and differential evolution (DE). Int J Adv Manuf Technol 73:509–519

Zhang JW, Peng AH (2012) Process-parameter optimization for fused deposition modeling based on Taguchi method. Adv Mater Res 538:444–447 Trans Tech Publ

Mireles J, Adame A, Espalin D, Medina F, Winker R, Hoppe T, Zinniel B, Wicker R (2011) Analysis of sealing methods for fdm-fabricated parts. Proceeding from Solid Free-form Fabrication Symposium, p 185–196

Galantucci LM, Lavecchia F, Percoco G (2009) Experimental study aiming to enhance the surface finish of fused deposition modeled parts. CIRP Ann Manuf Technol 58:189–192

Kannan S, Senthilkumaran D (2014) Investigating the influence of electroplating layer thickness on the tensile strength for fused deposition processed ABS thermoplastics. Int J Eng Technol 6:1047–1052

Kannan S, Senthilkumaran D (2014) Assessment of mechanical properties of Ni-coated abs plastics using FDM process. IJMME-IJENS 14:30–35

Gajdoš I, Spišák E, Kaščák Ľ, Krasinskyi V (2015) Surface Finish Techniques for FDM Parts. Materials Science Forum, vol 818. Trans Tech Publications, p 45–48

Gajdos I, Slota J (2010) Improving surface finish quality of FDM prototypes. Zeszyty Naukowe Politechniki Rzeszowskiej. Mechanika, p 87–90

Dewey MP, Ulutan D (2017) Development of laser polishing as an auxiliary post-process to improve surface quality in fused deposition modeling parts

Rosa B, Mognol P, Hascoët J-Y (2015) Laser polishing of additive laser manufacturing surfaces. J Laser Appl 27:S29102

Ukar E, Lamikiz A, de Lacalle LL, del Pozo D, Arana J (2010) Laser polishing of tool steel with CO 2 laser and high-power diode laser. Int J Mach Tools Manuf 50:115–125

Pfefferkorn FE, Duffie NA, Li X, Vadali M, Ma C (2013) Improving surface finish in pulsed laser micro polishing using thermocapillary flow. CIRP Ann Manuf Technol 62:203–206

Hafiz AMK, Bordatchev EV, Tutunea-Fatan RO (2012) Influence of overlap between the laser beam tracks on surface quality in laser polishing of AISI H13 tool steel. J Manuf Process 14:425–434

Lamikiz A, Sanchez J, de Lacalle LL, Arana J (2007) Laser polishing of parts built up by selective laser sintering. Int J Mach Tools Manuf 47:2040–2050

Ukar E, Lamikiz A, Lopez De Lacalle L, Del Pozo D, Liebana F, Sanchez A (2010) Laser polishing parameter optimisation on selective laser sintered parts. Int J Mach Mach Mater 8:417–432

Rosa B, Hascoët J-Y, Mognol P (2014) Topography modeling of laser polishing on AISI 316L milled surfaces. Mech Indust 15:51–61

Wang Q, Morrow JD, Ma C, Duffie NA, Pfefferkorn FE (2015) Surface prediction model for thermocapillary regime pulsed laser micro polishing of metals. J Manuf Process 20:340–348

Muller P, Mognol P, Hascoet J-Y (2013) Modeling and control of a direct laser powder deposition process for Functionally Graded Materials (FGM) parts manufacturing. J Mater Process Technol 213:685–692

Vadali M, Ma C, Duffie NA, Li X, Pfefferkorn FE (2012) Pulsed laser micro polishing: surface prediction model. J Manuf Process 14:307–315

Ramos J, Bourell D, Beaman J (2003) Surface over-melt during laser polishing of indirect-SLS metal parts. DTIC Document

Potente H, Karger O, Fiegler G (2002) Laser and microwave welding—the applicability of new process principles. Macromol Mater Eng 287:734–744

Rodríguez-Vidal E, Quintana I, Gadea C (2014) Laser transmission welding of ABS: effect of CNTs concentration and process parameters on material integrity and weld formation. Opt Laser Technol 57:194–201

Wang Z, Chen T, He P, Zuo T (2000) Calculation of mode contents of high-power CO 2 laser beam according to the changes of transverse intensity distribution. Opt Commun 175:215–220

Ilie M, Cicala E, Grevey D, Mattei S, Stoica V (2009) Diode laser welding of ABS: experiments and process modeling. Opt Laser Technol 41:608–614

Rodríguez-Vidal E, Quintana I, Etxarri J, Azkorbebeitia U, Otaduy D, González F, Moreno F (2012) Optical design and development of a fiber coupled high-power diode laser system for laser transmission welding of plastics. Opt Eng 51:124301–124301

Bachmann FG, Russek UA (2002) Laser welding of polymers using high-power diode lasers. High-power lasers and applications. International Society for Optics and Photo-Dermatology, p 505–518

Brewster MQ (1992) Thermal radiative transfer and properties. 1991:1–99

Lasprilla AJ, Martinez GA, Lunelli BH, Jardini AL, Maciel Filho R (2012) Poly-lactic acid synthesis for application in biomedical devices—a review. Biotechnol Adv 30:321–328

Martin O, Averous L (2001) Poly (lactic acid): plasticization and properties of biodegradable multiphase systems. Polymer 42:6209–6219

Garlotta D (2001) A literature review of poly(lactic acid). J Polym Environ 9:63–84

Standard I 25178-2, Surface texture: areal. Parts

Snakenborg D, Klank H, Kutter JP (2003) Microstructure fabrication with a CO2 laser system. J Micromech Microeng 14:182

Acknowledgements

The authors are thankful to Mr. Khu Vu in the Research School Physics, Dr. Hua Chen in the Centre of Advanced Microscope, and Chao Hu in the Research School of Engineering at the Australian National University for the technical assistance.

Funding

This work has been financially supported by the Australian Research Council PhD Scholarship (LP150100343).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Chai, Y., Li, R.W., Perriman, D.M. et al. Laser polishing of thermoplastics fabricated using fused deposition modelling. Int J Adv Manuf Technol 96, 4295–4302 (2018). https://doi.org/10.1007/s00170-018-1901-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-1901-5