Abstract

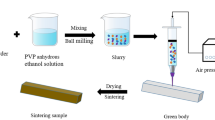

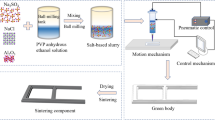

Layered extrusion forming, a type of additive manufacturing technique, was applied in this study, using aqueous ceramic pastes to build near-net-shaped ceramic cores at room temperature. As an example, aqueous-based pastes of alumina using methylcellulose (MC) as binder were prepared, and layered extrusion forming method was employed to fabricate green alumina cores. Afterwards, post sintering was carried out to obtain ceramic cores with high strength. Pastes with alumina solid loading varying from 30 to 52 vol.% were dispersed by MC solutions and presented shear-thinning rheological behaviors. Solid loading had a significant effect on the processing of layered extrusion formation. Alumina pastes with 30 to 46 vol.% were not suitable for layered extrusion formation, while pastes with solid loading ranging from 48 to 52 vol.% could be applied successfully to the layered extrusion forming process. Pastes composed of 2 wt.% MC solution as binder and 50 vol.% solid loading generated specimens with best shape retention and surface consistency, and the height of each layer extruded was equally distributed. The green specimens exhibited slightly smaller dimensions than the designed ones, and sintered specimens showed linear shrinkage. Sintered specimens presented homogeneous morphology, and no gap between extruded filaments was observed. Specimens sintered at 1600 °C for 180 mins possessed best comprehensive performances and low thermal expansion, which could meet the requirements of ceramic cores in alloys casting. The systematic study of layered extrusion forming indicates that this method is a promising method to fabricate ceramic cores.

Similar content being viewed by others

References

Kim Y, Yeo J, Lee J, Choi S (2016) Influence of silicon carbide as a mineralizer on mechanical and thermal properties of silica-based ceramic cores. Ceram Int 42:14738–14742. https://doi.org/10.1016/j.ceramint.2016.06.100

Liu F, Fan Z, Liu X, He J, Li F (2016) Aqueous gel casting of water-soluble calcia-based ceramic core for investment casting using epoxy resin as a binder. Int J Adv Manuf Technol 86:1235–1242. https://doi.org/10.1007/s00170-015-8227-3

Gromada M, Świeca A, Kostecki M, Olszyna A, Cygan R (2015) Ceramic cores for turbine blades via injection moulding. J Mater Process Technol 220:107–112. https://doi.org/10.1016/j.jmatprotec.2015.01.010

Cai KF, Nan CW, Schmuecker M, Mueller E (2003) Microstructure of hot-pressed B4C-TiB2 thermoelectric composites. J Alloys Compd 350:313–318. https://doi.org/10.1016/S0925-8388(02)00993-3

Yang S, Zhao YF (2015) Additive manufacturing-enabled design theory and methodology: a critical review. Int J Adv Manuf Technol 80:327–342. https://doi.org/10.1007/s00170-015-6994-5

Zhao H, Ye C, Fan Z, Wang C (2017) 3D printing of CaO-based ceramic core using nanozirconia suspension as a binder. J Eur Ceram Soc 37:5119–5125. https://doi.org/10.1016/j.jeurceramsoc.2017.06.050

Liu F, Liao Y (2010) Fabrication of inner complex ceramic parts by selective laser gelling. J Eur Ceram Soc 30:3283–3289. https://doi.org/10.1016/j.jeurceramsoc.2010.08.001

Bae C, Halloran JW (2011) Integrally cored ceramic mold fabricated by ceramic stereolithography. Int J Appl Ceram Technol 8:1255–1262. https://doi.org/10.1111/j.1744-7402.2010.02568.x

Moon Y, Choi I, Koh Y, Kim H (2015) Porous alumina ceramic scaffolds with biomimetic macro/micro-porous structure using three-dimensional (3-D) ceramic/camphene-based extrusion. Ceram Int 41:12371–12377. https://doi.org/10.1016/j.ceramint.2015.06.069

Costakis WJ, Rueschhoff LM, Diaz-Cano AI, Youngblood JP, Trice RW (2016) Additive manufacturing of boron carbide via continuous filament direct ink writing of aqueous ceramic suspensions. J Eur Ceram Soc 36:3249–3256. https://doi.org/10.1016/j.jeurceramsoc.2016.06.002

Hotta M, Shimamura A, Kondo N, Ohji T (2016) Powder layer manufacturing of alumina ceramics using water spray bonding. J Ceram Soc Jpn 124:750–752. https://doi.org/10.2109/jcersj2.16041

Wu H, Li D, Chen X, Sun B, Xu D (2010) Rapid casting of turbine blades with abnormal film cooling holes using integral ceramic casting molds. Int J Adv Manuf Technol 50:13–19. https://doi.org/10.1007/s00170-009-2502-0

Franchin G, Scanferla P, Zeffiro L, Elsayed H, Baliello A, Giacomello G, Pasetto M, Colombo P (2017) Direct ink writing of geopolymeric inks. J Eur Ceram Soc 37:2481–2489. https://doi.org/10.1016/j.jeurceramsoc.2017.01.030

Zhou K, Zhang X, Chen Z, Shi L, Li W (2015) Preparation and characterization of hydroxyapatite-sodium alginate scaffolds by extrusion freeforming. Ceram Int 41:14029–14034. https://doi.org/10.1016/j.ceramint.2015.07.016

Jo I, Ahn M, Moon Y, Koh Y, Kim H (2014) Novel rapid direct deposition of ceramic paste for porous biphasic calcium phosphate (BCP) scaffolds with tightly controlled 3-D macrochannels. Ceram Int 40:11079–11084. https://doi.org/10.1016/j.ceramint.2014.03.125

Fu Q, Saiz E, Tomsia AP (2011) Direct ink writing of highly porous and strong glass scaffolds for load-bearing bone defects repair and regeneration. Acta Biomater 7:3547–3554. https://doi.org/10.1016/j.actbio.2011.06.030

Li Y, Li L, Li B (2015) Direct ink writing of 3-3 piezoelectric composite. J Alloys Compd 620:125–128. https://doi.org/10.1016/j.jallcom.2014.09.124

Lu ZL, Fan YX, Miao K, Jing H, Li DC (2014) Effects of adding aluminum oxide or zirconium oxide fibers on ceramic molds for casting hollow turbine blades. Int J Adv Manuf Technol 72:873–880. https://doi.org/10.1007/s00170-014-5723-9

Wang N, Wang W, Jiang R, Cui K, Cao X (2017) Ceramic core shifting monitoring through clamping rods optimization for wax pattern of turbine blade. Int J Adv Manuf Technol 91:2193–2204. https://doi.org/10.1007/s00170-016-9943-z

Wiesner VL, Rueschhoff LM, Diaz-Cano AI, Trice RW, Youngblood JP (2016) Producing dense zirconium diboride components by room-temperature injection molding of aqueous ceramic suspensions. Ceram Int 42:2750–2760. https://doi.org/10.1016/j.ceramint.2015.11.005

Huang M, He P, Yang J, Duan F, Lim SC, Yip MS (2014) Fabrication and characterization of mini alumina ceramic turbine rotor using a tailored gelcasting process. Ceram Int 40:7711–7722. https://doi.org/10.1016/j.ceramint.2013.12.112

Rueschhoff L, Costakis W, Michie M, Youngblood J, Trice R (2016) Additive manufacturing of dense ceramic parts via direct ink writing of aqueous alumina suspensions. Int J Appl Ceram Technol 13:821–830. https://doi.org/10.1111/ijac.12557

Wang F, Yin J, Yao D, Xia Y, Zuo K, Xu J, Zeng Y (2016) Fabrication of porous SiC ceramics through a modified gelcasting and solid state sintering. Mater Sci Eng A 654:292–297. https://doi.org/10.1016/j.msea.2015.12.061

Qin Y, Pan W (2009) Effect of silica sol on the properties of alumina-based ceramic core composites. Mater Sci Eng A 508:71–75. https://doi.org/10.1016/j.msea.2008.12.016

Ronald J. Keller RSHJ (2003). Ceramic core and method of making. U.S. Patent No.6578623, 2003.06.17

Acknowledgements

The authors would like to express appreciations to the National Nature Science Foundation of China (NFSC) (No. 51775204), Research Project of State Key Laboratory of Materials Processing and Die & Mould Technology, HUST, and the Analytical and Testing Center, HUST.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tang, S., Fan, Z., Zhao, H. et al. Layered extrusion forming—a simple and green method for additive manufacturing ceramic core. Int J Adv Manuf Technol 96, 3809–3819 (2018). https://doi.org/10.1007/s00170-018-1712-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-1712-8