Abstract

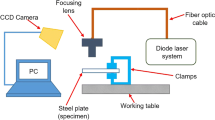

This research reports on the effect of workpiece geometry using circular scan patterns in low output power multi-pass laser forming processes applied to graphite coated AISI 304 stainless steel 0.6-mm-thick sheets. Curved plates, both circular and ring sectors, with multiple circular concentric laser path irradiation have been bent applying a fiber laser beam of diameter 1.2 mm, power 27 W power, and moving with a scanning velocity of 10 mm/s. Their behaviors are compared with those of rectangular plates linearly irradiated. In order to study the different variables that affect the bending plates with circular and linear patterns, finite element simulations of the forming processes have been carried out. Geometrical experimental measurements validate this formulation which, in turn, provides information about evolutions of the temperature, strain, and stress fields in the plate. A noticeable spring-back effect has been predicted for the curved sheets where, in addition, a direct relationship between equivalent plastic strain and bending angle could not be established. In such situations, the geometric shape of the plates was found to have a marked influence on the plate deformation.

Similar content being viewed by others

References

Edwardson SP (1999) Laser forming dish shapes—a 3D case study. Master Science (Engineering) Thesis, The University of Liverpool

Vollerstsen F (1995) Applications of lasers for flexible shaping processes. Proceedings of the 12th International Congress (LASER’95) Meisenbach, pp 151–162

Cheng P, Fan Y, Zhang J, Yao YL, Mika DP, Zhang W, Graham M, Marte J, Jones M (2006) Laser forming of varying thickness plate-part I: process analysis. ASME J Manuf Sci Eng 128(3):634–641. https://doi.org/10.1115/1.2172280

Cheng P, Fan Y, Zhang J, Yao YL, Mika DP, Zhang W, Graham M, Marte J, Jones M (2006) Laser forming of varying thickness plate-part II: process synthesis. ASME J Manuf Sci Eng 128(3):642–650. https://doi.org/10.1115/1.2162912

Wu D, Zhang Q, Ma G, Guo Y, Guo D (2010) Laser bending of brittle materials. Opt Lasers Eng 48(4):405–410. https://doi.org/10.1016/j.optlaseng.2009.09.009

Safari M, Farzin M, Ghaei A (2013) Introduction into the effects of process parameters on bending angle in the laser bending of tailor machined blank based on a statistical analysis. J Laser Appl 25:1–10

Shen H, Vollertsen F (2009) Modelling of laser forming—a review. Comput Mater Sci 46(4):834–840. https://doi.org/10.1016/j.commatsci.2009.04.022

Dahotre N, Harimkar S (2008) Laser fabrication and machining of materials. Springer, New York

Paunoiu V, Squeo EA, Quadrini F, Gheorghies C, Nicoara D (2008) Laser bending of stainless steel sheet metals. Int J Mater Forum Supply 1(S1):1371–1374. https://doi.org/10.1007/s12289-008-0119-8

Magee J, Watkins KG, Steen WM, Cooke RL, Sidhu J (1998) Development of an integrated laser forming demonstrator system for the aerospace industry. Proceedings of ICALEO’98, Section E, pp 141–150

Magee J, Watkins KG, Steen WM, Calder NJ, Sidhu J, Kirby J (1997) Laser forming of aerospace alloys. Proceedings of ICALEO’97, Section E, pp 156–165

Magee J, Watkins KG, Steen WM (1998) Advances in laser forming. J Laser Appl 10(6):235–246. https://doi.org/10.2351/1.521859

Frackiewicz H (1996) High-technology metal forming. Ind Laser Rev. Penn Well Publishing Co:15–17

Maji K, Shukla R, Nath AK, Pratihar DK (2013) Finite element analysis and experimental investigations on laser bending of AISI304 stainless steel sheet. Procedia Eng 64:528–535. https://doi.org/10.1016/j.proeng.2013.09.127

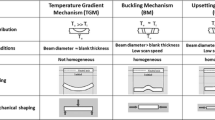

Geiger M, Vollertsen F (1993) The mechanism of laser forming. CIRP Ann 42(1):301–304. https://doi.org/10.1016/S0007-8506(07)62448-2

Shi Y, Yao Z, Shen H, Hu J (2006) Research on the mechanisms of laser forming for the metal plate. Int J Mach Tool Manu 46:689–1697

Cook F, Jacobsen V, Celentano D, Ramos J (2015) Characterization of the absorptance of laser irradiated steel sheets. J Laser Appl 27(3):032006–1–8. https://doi.org/10.2351/1.4918975

Shen H, Shi Y, Yao Z (2006) Numerical simulation of laser forming of plates using two simultaneous scans. Comput Mater Sci 37(3):239–245. https://doi.org/10.1016/j.commatsci.2005.06.012

Hu Z, Labudovic M, Wang H, Kovacevic R (2001) Computer simulation and experimental investigation of sheet metal bending using laser beam scanning. Int J Mach Tool Manu 41(4):589–607. https://doi.org/10.1016/S0890-6955(00)00058-4

Yanjin G, Sheng S, Guoqun Z, Yiguo L (2003) Finite element modeling of laser bending of pre-loaded sheet metals. J Mater Process Technol 142(2):400–407. https://doi.org/10.1016/S0924-0136(03)00603-4

Zhang L, Reutzel EW, Michaleris P (2004) Finite element modeling discretization requirements for the laser forming process. Int J Mech Sci 46(4):623–637. https://doi.org/10.1016/j.ijmecsci.2004.04.001

Stevens V, Celentano D, Ramos-Grez J, Walczak M (2012) Experimental and numerical analysis of low output power laser bending of thin steel sheets. J Manuf Sci Eng 134(3):031010. https://doi.org/10.1115/1.4005807

Cook F, Celentano D, Ramos-Grez J (2016) Experimental-numerical methodology for the manufacturing of cranial prosthesis via laser forming. Int J Adv Manuf Technol 86(5-8):2187–2196. https://doi.org/10.1007/s00170-015-8316-3

Vollertsen F. (1994) An analytical model for laser bending. Lasers Eng 2:261–276

Liu FR, Chan KC, Tang CY (2005) Theoretical analysis of deformation behavior of aluminum matrix composites in laser forming. Mater Sci Eng A 396(1-2):172–180. https://doi.org/10.1016/j.msea.2005.01.036

Mucha Z (2007) Deformations and stresses induced in materials by moving beam of CO2 laser. Proc SPIE 6598:65980M-1–65980M-9

Lambiase F (2012) An analytical model for evaluation of bending angle in laser forming of metal sheets. J Mater Eng Perform 21(10):2044–2052. https://doi.org/10.1007/s11665-012-0163-x

Shichun W, Zhong J (2002) FEM simulation of the deformation field during the laser forming of sheet metal. J Mater Process Technol 121(2-3):269–272. https://doi.org/10.1016/S0924-0136(01)01241-9

Liu FR, Chan KC, Tang CY (2007) Numerical simulation of laser forming of aluminum matrix composites with different volume fractions of reinforcement. Mater Sci Eng A 458(1-2):48–57. https://doi.org/10.1016/j.msea.2006.12.110

Che Jamil MS, Sheikh MA, Li L (2011) A numerical study of the temperature gradient mechanism in laser forming using different laser beam geometries. Lasers Eng 22:413–428

Smith TM, Michaleris P, Reutzel EW, Hall B (2012) Finite element model of pulsed laser forming. Proceedings of LPM2012- the 13th International Symposium on Laser Precision Microfabrication

Safari M (2014) Numerical investigation of the effect of process and sheet parameters on bending angle in the laser bending process. World J Mech 4(04):97–101. https://doi.org/10.4236/wjm.2014.44011

Magee J, Watkins KG, Steen WM, Calder N, Sidhu J, Kirby J (1997) Edge effects in laser forming. Laser Assist Net Shape Eng Proc LANE 2:399–408

Bao J, Yao YL (2001) Analysis and prediction of edge effects in laser bending. J Manuf Sci Eng 123(1):53–61. https://doi.org/10.1115/1.1345729

Shen H, Yao ZQ (2008) Analysis of varying velocity scanning schemes on bending angle in laser forming. International Workshop on Thermal Forming and Welding Distortion, pp 215–227

Cheng J, Yao YL (2001) Cooling effects in multiscan laser forming. J Manuf Process 3(1):60–72. https://doi.org/10.1016/S1526-6125(01)70034-5

Edwardson SP, Abed E, Bartkowiak K, Dearden G, Watkins KG (2006) Geometrical influences on multi-pass laser forming. J Phys D Appl Phys 39(2):382–389. https://doi.org/10.1088/0022-3727/39/2/021

Edwardson SP, Abed E, Carey C, Edwards KR, Dearden G, Watkins KG (2007) Factors influencing the bend per pass in multi-pass laser forming. Laser Assist Net Shape Eng Proc LANE 5:557–568

Shen H, Zhou J, Yao ZQ (2007) Study on overlapping of two sequential scans in laser forming. Proc Inst Mech Eng C J Mech Eng Sci (9):993–997

Liu J, Sun S, Guan Y, Ji Z (2010) Experimental study on negative laser bending process of steel foils. Opt Lasers Eng 48(1):83–88. https://doi.org/10.1016/j.optlaseng.2009.07.019

Hoseinpour Gollo M, Moslemi Naeini H, Payganeh GH, Ding S, Mahdavian S.M (2012) Experimental analyses of bending angle by a pulsed Nd:YAG laser in sheet metal forming process. Sci Res Essays 7:279–287

Pence C, Ding H, Shen N, Ding H (2013) Experimental analysis of sheet metal micro-bending using a nanosecond-pulsed laser. Int J Adv Manuf Technol 69(1-4):319–327. https://doi.org/10.1007/s00170-013-5032-8

Shen H, Ran M, Hu J, Yao Z (2014) An experimental investigation of underwater pulsed laser forming. Opt Lasers Eng 62:1–8. https://doi.org/10.1016/j.optlaseng.2014.04.011

Chen D, Wu S, Li M (2004) Deformation behaviours of laser curve bending of sheet metals. J Mater Process Technol 148(1):30–34. https://doi.org/10.1016/j.jmatprotec.2003.12.024

Venkadeshwaran K, Das S, Misra D (2010) Finite element simulation of 3-D laser forming by discrete section circle line heating. Int J Eng Sci Technol 2:163–175

Chakraborty S, Racherla V, Nath A (2012) Parametric study on bending and thickening in laser forming of a bowl shaped surface. Opt Lasers Eng 50(11):1548–1558. https://doi.org/10.1016/j.optlaseng.2012.06.003

Gautam S, Singh S, DixiU (2015) Laser forming of mild steel sheets using different surface coatings. Lasers Based Manuf Top Min Metall Mater Eng. https://doi.org/10.1007/978-81-322-2352-8_2

Peng Z, Jingbo Y, Xiongfei Z (2009) Deformation behaviors of laser forming of ring sheet metals. Tsinghua Sci Technol 14:132–136

Nadeem Q, Seong WJ, Na SJ (2012) Process designing for laser forming of circular sheet metal. Chin Opt Lett 10(2):021405–021407. https://doi.org/10.3788/COL201210.021405

Nadeem Q, Na SJ (2013) An approach to form the dome shape by 3D laser forming. Chin Opt Lett 11(2):021402–021405. https://doi.org/10.3788/COL201311.021402

Hennige T (2000) Development of irradiation strategies for 3D-laser forming. J Mater Process Technol 103(1):102–108. https://doi.org/10.1016/S0924-0136(00)00392-7

Nadeem Q, Na SJ (2011) Deformation behavior of laser bending of circular sheet metal. Chin Opt Lett 9(5):051402–051406. https://doi.org/10.3788/COL201109.051402

Berretta JR, de Rossi W, Martins das Neves MD, Alves de Almeida I, Dias Vieira Junior N (2007) Pulsed Nd:YAG laser welding of AISI 304 to AISI 420 stainless steel. Opt Lasers Eng 45(9):960–966. https://doi.org/10.1016/j.optlaseng.2007.02.001

Celentano D (2002) Thermomechanical analysis of the tensile test: simulation and experimental validation. Struct Eng Mech 13(6):591–614. https://doi.org/10.12989/sem.2002.13.6.591

Bao J, Yao YL (2001) Analysis and prediction of edge effects in laser bending. ASME J Manuf Sci Eng 123:53–61

Jha GC, Nath AK, Roy SK (2008) Study of edge effect and multi-curvature in laser bending of AISI 304 stainless steel. J Mater Process Technol 197(1-3):434–438. https://doi.org/10.1016/j.jmatprotec.2007.06.040

Acknowledgements

The support provided by the National Council for Scientific and Technological Research CONICYT (FONDECYT Project No. 1130404) is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Navarrete, Á., Celentano, D. Effect of workpiece geometry using circular scan patterns in sheet laser forming processes. Int J Adv Manuf Technol 96, 1835–1846 (2018). https://doi.org/10.1007/s00170-018-1628-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-1628-3