Abstract

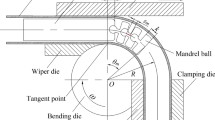

In order to investigate the influence of mandrel on the forming quality of bending L-shaped hollow parts, three types of mandrels, which are polyurethane rubber mandrel, low-melting-point mandrel, and ball bearing mandrel. Polyurethane rubber mandrel and low-melting-point mandrel, which supposed as elastic–plastic deformable part in the numerical simulation. The effect of different forms of mandrel on the forming quality of L-shaped hollow parts, such as section deformation and wall thickness variation, were compared with push bending without a mandrel. The results show that the low-melting-alloy mandrel leads to a better formability and a more uniform tube thickness distribution compared with the polyurethane rubber mandrel and ball bearing mandrel, for the low-point-melting mandrel brings about smaller stress in the bending process. Cold push-bending trials of rectangular cross-section tubes were conducted successfully based on the finite element simulation results. The experimental results showed that the formability and quality of L-shaped tubes greatly improved compared to no mandrel, ball bearing mandrel, and rubber mandrel when the low-melting-point-alloy mandrel was used as the flexible mandrel.

Similar content being viewed by others

References

Ku TW, Cha JH, Kim YB, Kwak OG, Kim WS, Kang BS (2013) A study on process parameters for cold U-bending of SUS304L heat transfer tube using rotary draw bending [J]. J Mech Sci Technol 27(10):3053–3061. https://doi.org/10.1007/s12206-013-0825-0

Li H, Yan H, Zhan M, Gu RJ (2007) The interactive effects of wrinkling and other defects in thin-walled tube NC bending process [J]. J Mater Process Technol 87–188(3):502–507

Lima RJDS, Thome JR (2012) Two-phase flow patterns in U-bends and their contiguous straight tubes for different orientations, tube and bend diameters [J]. Int J Refrig 35(5):1439–1454. https://doi.org/10.1016/j.ijrefrig.2012.02.002

Daxin E, Liu Y, Feng H (2010) Deformation analysis for the rotary draw bending process of circular tubes: stress distribution and wall thinning [J]. Steel Research International 81(12):1084–1088. https://doi.org/10.1002/srin.201000109

Zhu YX, Liu YL, Yang H (2015) Effect of mandrel-cores on springback and sectional deformation of rectangular H96 tube NC bending [J]. Int J Adv Manuf Technol 78(1–4):351–360. https://doi.org/10.1007/s00170-014-6657-y

Shi SC, Yang LF, Guo C (2011) Deformation behaviors of tube rotary-draw bending filled with steel balls [J]. Adv Mater Res 328–330:1403–1407. https://doi.org/10.4028/www.scientific.net/AMR.328-330.1403

Liu K, Liu Y, Yang H (2015) A study on mandrel role in rotary draw bending of rectangular tube [J]. Int J Mater Prod Technol 50(1):65. https://doi.org/10.1504/IJMPT.2015.066867

Zhao GY, Liu YL, Yang H, Lu CH, Gu RJ (2009) Three-dimensional finite-elements modeling and simulation of rotary-draw bending process for thin-walled rectangular tube [J]. Mater Sci Eng 499(1):257–261. https://doi.org/10.1016/j.msea.2007.11.127

Guo X, Tao J, Yuan Z (2011) Effects of rigid mandrel and lubrication on the process of elbow parts by cold push-bending [J]. J Comput Theor Nanosci 4(8):2618–2622

Zhu YX, Liu YL, Li HP, Yang H (2013) Comparison between the effects of PVC mandrel and mandrel-cores die on the forming quality of bending rectangular H96 tube [J]. Int J Mech Sci 76(6):132–143. https://doi.org/10.1016/j.ijmecsci.2013.09.011

ASME code book Specification for seamless ferrite and austenitic alloy-steel boiler, super-heater and heat-exchanger tubes, Section II Part A

S Baudin, P Ray, BJM Donald, MSJ Hashmi (2004) Development of a novel method of tube bending using finite element simulation [J]. J Mater Process Technol. s (22): 153–154

Zhao GY, Liu YL, Yang H, Cai-Hong LU (2010) Cross-sectional distortion behaviors of thin-walled rectangular tube in rotary-draw bending process. Trans Nonferrous Metals Soc China 20(3):484–489. https://doi.org/10.1016/S1003-6326(09)60166-7

Yang H, Li H, Zhan M (2010) Friction role in bending behaviors of thin-walled tube in rotary-draw-bending under small bending radii [J]. J Mater Process Technol 210(15):2273–2284. https://doi.org/10.1016/j.jmatprotec.2010.08.021

Zeng Y, Li Z (2002) Experimental research on the tube push-bending process [J]. J Mater Process Technol 122(2–3):237–240. https://doi.org/10.1016/S0924-0136(02)00027-4

Funding

The authors greatly acknowledge the financial support from the Natural Science Foundation of Jiangsu Province (grant No. BK20151469), the Research Fund of Nanjing University of Aeronautics and Astronautics (grant No. YAH17019), the Fundamental Research Funds for the Central Universities (grant No. NJ20150023, No. NJ20160035, and No. NJ20160036), and the Project funded by the Priority Academic Program Development of Jiangsu Higher Education Institutions.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Guo, Q., Ma, F., Guo, X. et al. Influence of mandrel on the forming quality of bending L-shaped hollow parts. Int J Adv Manuf Technol 95, 4513–4522 (2018). https://doi.org/10.1007/s00170-017-1536-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-1536-y