Abstract

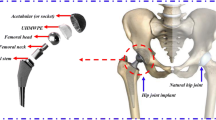

It is difficult to achieve nano-level surface finish on freeform surfaces. Femoral (knee joint) is one of such components which has freeform surface. Finishing operations are very costly and time consuming. Surface finish of femoral plays a major role in its functionality, efficiency, and life expectancy. To have uniform (or minimum variation) surface roughness value along its curvature, an inverse replica of the femoral component as a fixture has been designed and fabricated so that the magnetorheological (MR) fluid velocity is approximately constant in different areas of the femoral. In this work, an attempt has been made for achieving comparatively more uniform finish on different surfaces and reducing the time required for finishing femoral. For this, a special tooling is used in rotational-magnetorheological abrasive flow finishing (R-MRAFF) process. Different extrusion pressures have been used to examine the effect on percentage change in Ra, finishing rate, and final surface finish of the femoral in both directions, X and Y. Minimum surface roughness of 78 and 89 nm has been achieved on femoral from the initial surface roughness of 172 and 178 nm in X- and Y-directions, respectively.

Similar content being viewed by others

References

Jain VK (ed) (2016) Nanofinishing science and technology: basic and advanced finishing and polishing processes. December 22, 2016 by CRC Press, Reference - 655 Pages - 327 B/W Illustrations, ISBN 9781498745949 - CAT# K26967

Saito K (1984) Finishing and polishing of freeform surfaces. Bull Japan Soc Mech Eng 18:104–109

ASTM standard: F2083-11 standard specifications for total knee prosthesis, 1–9. https://doi.org/10.1520/F2083-11.2

Dalury DF, Pomeroy DL, Gorab RS, Adams MJ (2013) Why are total knee arthroplasties being revised? J Arthroplast 28(8):120–121. https://doi.org/10.1016/j.arth.2013.04.051

Gallo J, Goodman SB, Konttinen YT, Wimmer MA, Holinka M (2013) Osteolysis around total knee arthroplasty: a review of pathogenetic mechanisms. Acta Biomater 9(9):8046–8058. https://doi.org/10.1016/j.actbio.2013.05.005

Schroer WC, Berend KR, Lombardi AV, Barnes CL, Bolognesi MP, Berend ME, Ritter MA, Nunley RM (2013) Why are total knees failing today? Etiology of total knee revision in 2010 and 2011. J Arthroplasty 28(8):116–119. https://doi.org/10.1016/j.arth.2013.04.056

Nagdeve L, Jain VK, Ramkumar J (2016) Nano-finishing of freeform surfaces: a review. J Inst Eng India (IEI) Prod Div 1:50–57

Lasemi A, Xue D, Gu P (2010) Recent development in CNC machining of freeform surfaces: a state-of-the-art review. CAD Comput Aided Des 42(7):641–654. https://doi.org/10.1016/j.cad.2010.04.002

Sidpara AM Jain VK (2012) Nanofinishing of freeform surfaces of prosthetic knee joint implant. Proc Inst Mech Eng B J Eng Manuf 226(11):1833–1846. https://doi.org/10.1177/0954405412460452

Baghel P, Singh S, Nagdeve L, Jain VK, Dua Sharma N (2015) Preliminary investigations into finishing of artificial dental crown. Int J Precis Technol 5:229–245

Kumar S, Jain VK, Sidpara A (2015) Nanofinishing of freeform surfaces (knee joint implant) by rotational-magnetorheological abrasive flow finishing (R-MRAFF) process. Precis Eng 42:165–178. https://doi.org/10.1016/j.precisioneng.2015.04.014

Sarkar M, Jain VK (2015) Nanofinishing of freeform surfaces using abrasive flow finishing process. Proc Inst Mech Eng B J Eng Manuf 231(9):1501–1515. https://doi.org/10.1177/0954405415599913

Nagdeve L, Jain VK, Ramkumar J (2016) Experimental investigations into nano-finishing of freeform surfaces using negative replica of the knee joint. Procedia CIRP 42:793–798. https://doi.org/10.1016/j.procir.2016.02.321

Yamaguchi H, Graziano A (2014) Surface finishing of cobalt chromium alloy femoral knee components. CIRP Ann Manuf Technol 63(1):309–312. https://doi.org/10.1016/j.cirp.2014.03.020

Rosler. oberflachentechnik GmbH, Compact Drag Finisherhttp:/etypo3p.rosler.com/blaetterkatalog/blaetterkatalog/pdf/complete.pdf

OTEC prazisionsfinish GmbH. An Overview of the Machines. http://www.oteccusa.com/brochure.pdfs/Medical%20brouchure.pdf

Jha S, Jain VK (2004) Design and development of the magnetorheological abrasive flow finishing (MRAFF) process. Int J Mach Tools Manuf 44(10):1019–1029. https://doi.org/10.1016/j.ijmachtools.2004.03.007

Das M, Jain VK, Ghoshdastidar PS (2010) Nano-finishing of stainless-steel tubes using rotational magnetorheological abrasive flow finishing process. Mach Sci Technol 14(3):365–389. https://doi.org/10.1080/10910344.2010.511865

Rabinow J (1948) The magnetic fluid clutch. Trans Am Inst Electr Eng 67(2):1308–1315. https://doi.org/10.1109/T-AIEE.1948.5059821

Das M, Jain VK, Ghoshdastidar PS (2012) Nanofinishing of flat workpieces using rotational-magnetorheological abrasive flow finishing (R-MRAFF) process. Int J Adv Manuf Technol 62(1-4):405–420. https://doi.org/10.1007/s00170-011-3808-2

Sidpara A, Jain VK (2012) Magnetorheological fluid based nanofinishing of flat and freeform surfaces. Ph.D. Dissertation, Indian Institute of Technology, Kanpur, Kanpur India

Acknowledgements

We acknowledge the help of Manufacturing Science Lab and 4i Lab, IIT Kanpur for extending their facilities to fabricate fixtures for femoral and other devices. This paper is a revised and expanded version of the paper entitled “Preliminary investigations into nano-finishing of freeform surface (femoral) using inverse replica fixture” by Leeladhar Nagdeve, V. K. Jain, J. Ramkumar, presented at the 6th International and 27th AIMTDR Conference (2016) held at College of Engineering Pune, India, during 16–18 December 2016.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nagdeve, L., Jain, V.K. & Ramkumar, J. Preliminary investigations into nano-finishing of freeform surface (femoral) using inverse replica fixture. Int J Adv Manuf Technol 100, 1081–1092 (2019). https://doi.org/10.1007/s00170-017-1459-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-1459-7