Abstract

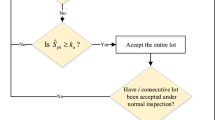

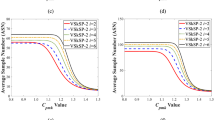

This paper develops Markovian-based models for determining the optimum process means with the consideration of an acceptance sampling plan in a serial production system. This paper studies a production system where products are produced continuously with specified lower and upper specification limits for each stage in the production system for quality assurance purposes. Considering the inherent variability in production processes, the quality characteristic(s) of a product might fall below the lower specification limit, resulting in scrap cost, or above the upper specification limit, resulting in rework costs. To study the dynamics of this problem, this paper first develops a Markovian-based model for the optimum process target level for a single quality characteristic assuming a single sampling inspection plan for both a single- and a two-stage production system. Then, the proposed model is extended for dual quality characteristics that are dependent for single- and two-stage production systems. Numerical examples and sensitivity analysis are performed to investigate the effect of different system parameters on the expected profit and optimum process means. The results showed that both single- and two-stage production systems have convex function for the expected profit. In addition, the results showed that the optimum process means are slightly larger than the average of the specification limits. Finally, the correlation between the quality characteristics affects the expected profit significantly.

Similar content being viewed by others

References

Bowling SR, Khasawneh MT, Kaewkuekool S, Cho BR (2004) A Markovian approach to determining optimum process target levels for a multi-stage serial production system. Eur J Oper Res 159:636–650

Lee MK, Elsayed EA (2002) Process mean and screening limits for filling processes under two-stage screening procedure. Eur J Oper Res 138:118–126

Chen CH, Chou CY (2003) Determining the optimum process mean under bivariate quality characteristics. Int J Adv Manuf Technol 21:193–195

Chan WM, Ibrahim RN (2004) Evaluating the quality level of a product with multiple quality characteristics. Int J Adv Manuf Technol 24:738–742

Chan WM, Ibrahim RN, Lochert PB (2005) Evaluating the product quality level under multiple L-type quality characteristics. Int J Adv Manuf Technol 27:90–95

Shao YE, Fowler JW, Runger GC (2005) A note on determining an optimum target by considering the dependence of holding costs and the quality characteristics. J Appl Stat 32:813–822

Teeravaraprug J (2005) Determining optimum process mean of two-market products. Int J Adv Manuf Technol 25:1248–1253

Khasawneh MT, Bowling SR, Cho BR (2008) A Markovian approach to determining optimum process means with dual quality characteristics in a multi-stage production system. J Syst Sci Syst Eng 17:66–85

Duffuaa SO, Al-Turki UM, Kolus AA (2009) Process-targeting model for a product with two dependent quality characteristics using acceptance sampling plans. Int J Prod Res 47:4031–4046

Selim SZ, Al-Zu’bi WK (2011) Optimum means for continuous processes in series. Eur J Oper Res 210:618–623

Springer CH (1951) A method for determining the most economic position of a process mean. Ind Qual Control 8:36–39

Bettes DC (1962) Finding an optimum target value in relation to a fixed lower limit and an arbitrary upper limit. Appl Stat 11:202–210

Hunter WG, Kartha CP (1977) Determining the most profitable target value for a production process. J Qual Technol 9:176–181

Bisgaard S, Hunter WG, Pallesen L (1984) Economic selection of quality of manufactured product. Technometrics 26:9–18

Golhar DY (1987) Determination of the best mean contents for a canning problem. J Qual Technol 19:82–84

Vidal RV (1988) A graphical method to select the optimum target value of a process. Eng Optim 13:285–291

Arcelus FJ, Rahim MA (1990) Optimum process levels for the joint control of variables and attributes. Eur J Oper Res 45:224–230

Boucher TO, Jafari MA (1991) The optimum target value for single filling operations with quality plans. J Qual Technol 23:44–47

Elsayed EA, Chen A (1993) Optimum levels of process parameters for products with multiple characteristics. Int J Prod Res 31:1117–1132

Al-Sultan KS (1994) An algorithm for determination of the optimum target values for two machines in series with quality sampling plan. Int J Prod Res 32:37–45

Chen S, Chung K (1996) Selection of the optimum precision level and target value for a production process: The lower specification-limit case. IIE Trans 28:979–985

Liu W, Raghavachari M (1997) The target mean problem for an arbitrary quality characteristic distribution. Int J Prod Res 35:1713–1727

Al-Sultan KS, Pulak MFS (2000) Optimum target values for two machines in series with 100 % inspection. Eur J Oper Res 120:181–189

Al-Fawzan MA, Rahim MA (2001) Optimum control of deteriorating process with a quadratic loss function. Int J Qual Reliab Eng 17:459–466

Cho BR (2002) Optimum process target for two quality characteristics using regression analysis. Qual Eng 15:37–47

Teeravaraprug J, Cho BR (2002) Designing the optimum process target levels for multiple quality characteristics. Int J Prod Res 40:37–54

Moroni G, Petrò S (2014) Optimal inspection strategy planning for geometric tolerance verification. Precis Eng 38:71–81

Montgomery DC (1991) Introduction to statistical quality control, 2nd edn. Wiley, New York

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Peng, CY., Khasawneh, M.T. A Markovian approach to determining optimum process means with inspection sampling plan in serial production systems. Int J Adv Manuf Technol 72, 1299–1323 (2014). https://doi.org/10.1007/s00170-014-5741-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-5741-7