Abstract

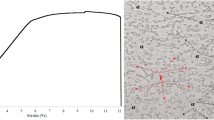

An experimental program of welding a titanium alloy, Ti-6Al-4V, was carried out using ultrahigh-frequency pulse gas tungsten arc welding (UHF-GTAW). The characteristics of the welds were investigated, such as the defection, microstructure, and mechanical properties. The experimental results show that the high pulse frequency reduces the heat input from the UHF-GTAW process, while gaining one-side welding with backing as a precondition. Basketweave and long acicular α′ martensite only existed in some areas of the FZ (fusion zone) with both low uniformity and distribution density (8.4 %) as a result of conventional GTAW processes. With a pulsed current, basketweave and short acicular α′ martensite were distributed in the FZ evenly. Short acicular α′ martensite could be detected within the parallel long acicular α′ martensite in the CGR when f > 30 kHz. Plastic weld joints were characterized by both the elongation, A, and the percentage of the area reduction, Z, and were optimized with a high pulse frequency. Ideal mechanical properties of the joints were achieved with an A of 68 % and a Z of 150 % with f = 30 kHz. The integrated effects of the pulse frequency and the heat input are the key factors for determining the microstructure morphology and the mechanical properties.

Similar content being viewed by others

References

Leyens C, Peters M (2003) Titanium and titanium alloys. Wiley-VCH, Weinheim

Boyer RR (1996) An overview on the use of titanium in the aerospace industry. Mat Sci Eng A-Struct 213:103–114

DDS, MSD, Wang RR et al (1995) Joining titanium materials with tungsten inert gas welding, laser welding and infrared brazing. J Prosthet Dent 74(5):521–530

Malinov S, Sha W (2004) Application of artificial neural networks for modeling correlations in titanium alloy. Mater Sci Eng A-Struct 365:202–211

Wang SH, Wei MD (2004) Tensile properties of gas tungsten arc weldments in commercially pure titanium, Ti-6Al-4V and Ti-15V-3Al-3Sn-3Cr alloys at different strain rates. Sci Technol Weld Joi 9:415–422

Qi Yunlian J, Deng QH, Zeng L (2000) Electron beam welding, laser beam welding and gas tungsten arc welding of titanium sheet. Mater Sci Eng A-Struct 280:177–181

Donachie MJ Jr (2000) Titanium: a technical guide, 2nd edn. ASM International, Materials Park

Baeslack WA III, Banas CM (1981) A comparative evaluation of laser and gas tungsten arc weldments in high temperature titanium alloys. Weld J 60:121s–130s

Peters JO, Luterjing G (2001) Comparison of the fatigue and fracture of α+β and β titanium alloys. Metall Mater Trans A 32A:2805–2818

Balasubramanian M, Jayabalan V, Balasubramanian V (2008) Developing mathematical models to predict tensile properties of pulsed current gas tungsten arc welded Ti-6Al-4V alloy. J Mater Des 29:92–97

Becker DW, Adams CM Jr (1979) The role of pulsed GTA welding variables in solidification and grain refinement. Weld J 58:143s–152s

Fude W, Stewart W, Matthew R (2011) Morphology investigation on direct current pulsed gas tungsten arc welded additive layer. Int J Adv Manuf Technol 57:597–603

Kishore Babu N, Ganesh Sundara Raman S (2006) Influence of current pulsing on microstructure and mechanical properties of Ti-6Al-4V TIG weldments. Sci Technol Weld Joi 11:442–447

Prasad Rao K (2001) Fusion zone grain refinement in GTA welds using magnetic arc oscillation and current pulsing. RAMP p. 176–96

Ge ZX, Chen HM, Ge Y (2004) Affection of arc-weld inversion power’s frequency on weld grain’s thinning. J Hot Work Technol 7:47–48

Balasubramanian V, Ravisankar V, Madhusudhan Reddy G (2008) Effect of pulsed current welding on mechanical properties of high strength aluminum alloy. Int J Adv Manuf Technol 36:254–262

Simpson RP (1977) Refinement of weld fusion zones in alpha-beta titanium alloys. Weld J 56–67s

Garland JG (1974) Weld pool solidification control. Met Constr 16:25

Kishore BN, Ganesh SRS, Mythili R et al (2007) Correlation of microstructure with mechanical properties of TIG weldments of Ti-6Al-4V made with and without current pulsing. Mater Charact 58:581–587

Sundaresan S, Janaki D et al (1999) Microstructural refinement of weld fusion zones in α-β titanium alloys using pulsed current welding. Mat Sci Eng A-Struct 262:88–100

Keshava Murthy K, Sundaresan S (1997) Fatigue crack growth behavior in a welded α-β Ti-Al-Mn alloy in relation to microstructural features. Mater Sci Eng A-Struct 222:201–211

Wei W, Hongming G, Lin W (2008) Microstructures in CGHAZ and mechanical properties of welded joint during welding of fine grain titanium alloy. Trans Chn Weld Inst 29:61–64

Ahmed T, Rack HJ (1998) Phase transformation during cooling in α+β titanium alloys. Mat Sci Eng A-Struct A243:206–211

Elmer JW, Palmer TA (2004) Phase transformation dynamics during welding of Ti-6Al-4V. J Appl Phys 95:8327–8339

Mingxuan Y, Bojin Q et al (2012) Microstructures and properties of titanium alloys welds using ultrasonic frequency pulse GTAW. Trans Chn Weld Inst 33:39–42

Karimzadeh F, Salehi M, Saatchi A et al (2005) Effect of microplasma arc welding process parameters on grain growth and porosity distribution of thin sheet Ti6Al4V alloy weldment. J Mater Manuf Process 20:205–219

Atapour M, Pilchak AL, Frankel GS, Williams JC (2010) Corrosion behavior of friction stir-processed and gas tungsten arc-welded Ti-6Al-4V. J Metall Mater Trans A 41(9):2318–2327

Atthey DR (1980) A mathematical model for fluid flow in a weld pool at high currents. J Fluid Mech 98(4):787–801

Qi BJ, Yang MX, Cong BQ, Liu FJ (2012) The effect of arc behavior on weld geometry by high frequency pulse GTAW process with 0Cr18Ni9Ti stainless steel. Int J Adv Manuf Technol. doi:10.1007/s00170-012-4438-z

Zuo JH, Wang ZG, Han EH (2008) Effect of microstructure on ultra-high cycle fatigue behavior of Ti-6Al-4V. J Mat Sci Eng A-Struct 473:147–152

Nakajima K, Terao K, Miyata T (1998) The effect of microstructure on fatigue crack propagation of α+β titanium alloys: in-situ observation of short fatigue crack growth. J Mat Sci Eng A-Struct 243(1–2):176–181

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, M., Qi, B., Cong, B. et al. Effect of pulse frequency on microstructure and properties of Ti-6Al-4V by ultrahigh-frequency pulse gas tungsten arc welding. Int J Adv Manuf Technol 68, 19–31 (2013). https://doi.org/10.1007/s00170-013-4822-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-013-4822-3