Abstract

In this paper, the thermodynamic configurational force associated with a moving interface is used to derive the conditions for phase growth and nucleation in bodies with multiple diffusing species and arbitrary surface stress at the phase interface. First, the mass, momentum and energy balances are derived on the evolving phase interface. The thermodynamic conditions that result from free energy inequality at the interface are derived leading to the analytical form of the configurational force for bodies subject to mechanical loads, heat and multiple diffusing species. The derived second law condition naturally extends the Eshelby energy–momentum tensor to include species diffusion terms. The above second law restriction is then used to derive the condition for the growth of new phases in a body undergoing finite deformation subject to inhomogeneous as well as anisotropic interface stress, and multiple diffusing species. The growth conditions are derived in both current and reference configurations. The statistical temperature-dependent growth velocity is next derived using the Boltzmann distribution. The derived finite deformation form of growth requirement is simplified to obtain the small deformation diffusive void growth condition. Next, a general, finite deformation, arbitrary surface stress form of phase nucleation condition is derived by considering uncertainty in growth of a small nucleus. The probability of nucleation is shown to naturally depend on a theoretical estimate of critical volumetric energy density, which is directly related to the surface stress. The classical nucleation theory is shown to result from a simplified special case of the general criterion. As an application of the developed theory, the classical Blech electromigration experiment is simulated to estimate the critical energy density corresponding to the onset of electromigration voids at Al–TiN interface.

Similar content being viewed by others

References

Jones, D.R., Ashby, M.F.: Engineering Materials 2: An Introduction to Microstructures, Processing and Design. Butterworth-Heinemann, Oxford (2005)

Tarascon, J.M., Armand, M.: Issues and challenges facing rechargeable lithium batteries. Nature 414(6861), 359–367 (2001)

Girishkumar, G., McCloskey, B., Luntz, A., Swanson, S., Wilcke, W.: Lithium–air battery: promise and challenges. J. Phys. Chem. Lett. 1(14), 2193–2203 (2010)

Sunwoo, A., Morris, J., Lucey, G.: The growth of cu-sn intermetallics at a pretinned copper–solder interface. Metall. Trans. A 23(4), 1323–1332 (1992)

Udupa, A., Sadasiva, S., Subbarayan, G.: A framework for studying dynamics and stability of diffusive–reactive interfaces with application to cu6sn5 intermetallic compound growth. Proc. R. Soc. Math. Phys. Eng. Sci. 472, 20160134 (2016)

Amar, M.B., Goriely, A.: Growth and instability in elastic tissues. J. Mech. Phys. Solids 53(10), 2284–2319 (2005)

Li, X., Magnuson, C.W., Venugopal, A., Tromp, R.M., Hannon, J.B., Vogel, E.M., Colombo, L., Ruoff, R.S.: Large-area graphene single crystals grown by low-pressure chemical vapor deposition of methane on copper. J. Am. Chem. Soc. 133(9), 2816–2819 (2011)

Wang, W., Suo, Z.: Shape change of a pore in a stressed solid via surface diffusion motivated by surface and elastic energy variation. J. Mech. Phys. Solids 45(5), 709–729 (1997)

Gleixner, R., Nix, W.: A physically based model of electromigration and stress-induced void formation in microelectronic interconnects. J. Appl. Phys. 86(4), 1932–1944 (1999)

Sukharev, V., Zschech, E.: A model for electromigration-induced degradation mechanisms in dual-inlaid copper interconnects: effect of interface bonding strength. J. Appl. Phys. 96(11), 6337–6343 (2004)

Xia, L., Bower, A.F., Suo, Z., Shih, C.: A finite element analysis of the motion and evolution of voids due to strain and electromigration induced surface diffusion. J. Mech. Phys. Solids 45(9), 1473–1493 (1997)

Basaran, C., Lin, M., Ye, H.: A thermodynamic model for electrical current induced damage. Int. J. Solids Struct. 40(26), 7315–7327 (2003)

Abeyaratne, R., Knowles, J.K.: On the driving traction acting on a surface of strain discontinuity in a continuum. J. Mech. Phys. Solids 38(3), 345–360 (1990)

Fried, E., Gurtin, M.E.: Coherent solid-state phase transitions with atomic diffusion: a thermomechanical treatment. J. Stat. Phys. 95(5–6), 1361–1427 (1999)

Gurtin, M.E.: Configurational Forces as Basic Concepts of Continuum Physics, vol. 137. Springer, Berlin (1999)

Lane, M., Liniger, E., Lloyd, J.: Relationship between interfacial adhesion and electromigration in cu metallization. J. Appl. Phys. 93(3), 1417–1421 (2003)

Avrami, M.: Kinetics of phase change II. Transformation-time relations for random distribution of nuclei. J. Chem. Phys. 8(2), 212–224 (1940)

Cahn, J.W.: The kinetics of grain boundary nucleated reactions. Acta Metall. 4(5), 449–459 (1956)

Christian, J.W.: The Theory of Transformations in Metals and Alloys. Newnes, London (2002)

Kelton, K., Greer, A.: Nucleation in Condensed Matter: Applications in Materials and Biology. Pergamon Materials Series, vol. 15. Pergamon, Oxford (2010)

Shatzkes, M., Lloyd, J.: A model for conductor failure considering diffusion concurrently with electromigration resulting in a current exponent of 2. J. Appl. Phys. 59(11), 3890–3893 (1986)

Lloyd, J., Kitchin, J.: The electromigration failure distribution: the fine-line case. J. Appl. Phys. 69(4), 2117–2127 (1991)

Chao, B., Chae, S.H., Zhang, X., Lu, K.H., Ding, M., Im, J., Ho, P.S.: Electromigration enhanced intermetallic growth and void formation in pb-free solder joints. J. Appl. Phys. 100(8), 084909 (2006)

Tu, K., Yeh, C., Liu, C., Chen, C.: Effect of current crowding on vacancy diffusion and void formation in electromigration. Appl. Phys. Lett. 76(8), 988–990 (2000)

Yeh, E.C., Choi, W., Tu, K., Elenius, P., Balkan, H.: Current-crowding-induced electromigration failure in flip chip solder joints. Appl. Phys. Lett. 80(4), 580–582 (2002)

Gleixner, R., Clemens, B., Nix, W.: Void nucleation in passivated interconnect lines: effects of site geometries, interfaces, and interface flaws. J. Mater. Res. 12(08), 2081–2090 (1997)

Clement, J., Thompson, C.: Modeling electromigration-induced stress evolution in confined metal lines. J. Appl. Phys. 78(2), 900–904 (1995)

Kirchheim, R.: Stress and electromigration in al-lines of integrated circuits. Acta Metall. Mater. 40(2), 309–323 (1992)

Bower, A.F., Shankar, S.: A finite element model of electromigration induced void nucleation, growth and evolution in interconnects. Model. Simul. Mater. Sci. Eng. 15(8), 923 (2007)

Xu, X.P., Needleman, A.: Void nucleation by inclusion debonding in a crystal matrix. Model. Simul. Mater. Sci. Eng. 1(2), 111 (1993)

Bhandakkar, T.K., Gao, H.: Cohesive modeling of crack nucleation under diffusion induced stresses in a thin strip: implications on the critical size for flaw tolerant battery electrodes. Int. J. Solids Struct. 47(10), 1424–1434 (2010)

Singh, N., Bower, A., Shankar, S.: A three-dimensional model of electromigration and stress induced void nucleation in interconnect structures. Model. Simul. Mater. Sci. Eng. 18(6), 065006 (2010)

Basaran, C., Nie, S.: An irreversible thermodynamics theory for damage mechanics of solids. Int. J. Damage Mech. 13(3), 205–223 (2004)

Yao, W., Basaran, C.: Computational damage mechanics of electromigration and thermomigration. J. Appl. Phys. 114(10), 103708 (2013)

Clemens, B., Nix, W., Gleixner, R.: Void nucleation on a contaminated patch. J. Mater. Res. 12(8), 2038–2042 (1997)

Truesdell, C., Toupin, R.: The classical field theories. In: Flügge, S. (ed.) Principles of Classical Mechanics and Field Theory/Prinzipien der Klassischen Mechanik und Feldtheorie, pp. 226–858. Springer, Berlin (1960)

Gurtin, M.E., Jabbour, M.E.: Interface evolution in three dimensions with curvature-dependent energy and surface diffusion: interface-controlled evolution, phase transitions, epitaxial growth of elastic films. Arch. Ration. Mech. Anal. 163(3), 171–208 (2002)

Gurtin, M.E., Fried, E., Anand, L.: The Mechanics and Thermodynamics of Continua. Cambridge University Press, New York (2010)

Eshelby, J.: The elastic energy–momentum tensor. J. Elast. 5(3–4), 321–335 (1975)

Rice, J.R.: A path independent integral and the approximate analysis of strain concentration by notches and cracks. J. Appl. Mech. 35(2), 379–386 (1968)

Landau, L.D., Lifshitz, E.M.: Statistical Physics, 2nd edn. Addison-Wesley Pub. Co., Reading (1969)

Servi, I., Turnbull, D.: Thermodynamics and kinetics of precipitation in the copper–cobalt system. Acta Metall. 14(2), 161–169 (1966)

LeGoues, F., Aaronson, H.: Influence of crystallography upon critical nucleus shapes and kinetics of homogeneous fcc–fcc nucleation. Comparisons between theory and experiment in cu–co alloys. Acta Metall. 32(10), 1855–1864 (1984)

Volmer, M., Weber, A.: Keimbildung in übersättigten gebilden. Z. Phys. Chem. 119, 277–301 (1926)

Turnbull, D., Fisher, J.C.: Rate of nucleation in condensed systems. J. Chem. Phys. 17(1), 71–73 (1949)

Blech, I.A.: Electromigration in thin aluminum films on titanium nitride. J. Appl. Phys. 47(4), 1203–1208 (1976)

Gurtin, M., Struthers, A., Williams, W.: A transport theorem for moving interfaces. Q. Appl. Math. 47(4), 773–777 (1989)

Acknowledgements

This study was partially supported by Intel Corporation and the Semiconductor Research Corporation under Task 1292.090.

Author information

Authors and Affiliations

Corresponding author

Additional information

Communicated by Andreas Öchsner.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Surface identities

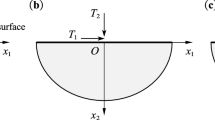

Following the definitions given in [37], the surface gradient is defined using the projection tensor:

where \(\mathbf {I}\) is the identity tensor and \(\mathbf {n}\) is the normal to the surface at the point of interest. Referring to Fig. 2, for a scalar field \(\phi _{\mathrm{s}}({\mathbf {x}}_{\mathrm{s}})\) defined on the subregion \({\varGamma }_{ \mathrm{s}}\) of \({\varGamma }\), the surface gradient operator is defined to relate the gradient of the field in its extension into the body as

where the quantity \(\nabla _{{\mathrm{s}}\,}\phi _{\mathrm{s}}\) is defined on the tangent plane at the point of interest. Similarly, for a vector field \(\mathbf {a}({\mathbf {x}}_{\mathrm{s}})\) defined on the surface \({\varGamma }_{ \mathrm{s}}\), the surface gradient operator and the surface divergence operators are defined as

Finally, for a second-order tensor field \(\mathbf {A}({\mathbf {x}}_{\mathrm{s}})\) defined on \({\varGamma }_{ \mathrm{s}}\), the two surface operators are similarly defined as,

The curvature tensor at any point on the surface and the total curvature are defined using the surface gradient as

where \(\kappa \) is the total curvature, or twice the mean value. The curvature tensor is fully tangential and symmetric. Further, from the above relationship, it is easy to show:

This gives a useful surface divergence product rule for any second-order tensor field \(\mathbf {A}({\mathbf {x}}_{\mathrm{s}})\),

We list next an identity that is useful for simplifications carried out in this paper. For smooth scalar and vector fields \(\phi ({\mathbf {x}}_{\mathrm{s}})\) and \(\mathbf {a}({\mathbf {x}}_{\mathrm{s}})\), respectively,

The surface divergence theorem for a tangential vector field \(\mathbf {a}_{\mathbf {t}}({\mathbf {x}}_{\mathrm{s}})\) defined on a subregion \({\varGamma }_{ \mathrm{s}}\) is:

where \(\mathbf {m}\) is tangent to the surface, but normal to the bounding curve \(\partial {\varGamma }_{ \mathrm{s}}\). For a superficial vector field with both normal and tangential components of the form \(\mathbf {a}=a_n\mathbf {n}+\mathbf {a}_{\mathbf {t}}\) such that \(a_n=\mathbf {a}\cdot \mathbf {n}\), the above surface divergence theorem can be generalized using Eqs. (95) and (92) as

Similarly for a superficial tensor field \(\mathbf {A}({\mathbf {x}}_{\mathrm{s}})\), the divergence theorem has the form,

Material time derivative of a bulk field

Given a field \(\phi (\mathbf {x},t)\), the material time derivative of the field is defined as [38]

Thus,

Surface transport theorem

The surface transport theorem then gives the rate of change of a superficial scalar field, \(\phi _{\mathrm{s}}({\mathbf {x}}_{\mathrm{s}}(t),t)\), defined on the interface [47]. The surface transport theorem can be derived using the concept of material time derivative:

By definition of material time derivative:

Now, the material time derivative of the differential surface element is [38]

Thus,

Kinematics of a coherent interface

We begin with the usual definition of the velocity of a particle at a spatial location \(\mathbf {x}\left( \mathbf {X},t\right) \) obtained by holding position in the reference configuration, \(\mathbf {X}\), fixed,

Now, we assume that the interface convects with the body and that different material particles come to occupy the interface at different instants of time. Hence, the interface can be viewed as evolving with time in both the reference and current configurations. Let \({\mathbf {X}}_{\mathrm{S}}\left( t\right) \) denote the reference coordinate of particles on the interface at time t. Then, the interface velocity as viewed in the reference configuration is given by [37],

Similarly, the velocity of the interface in the current configuration is,

The first term \( \mathbf {v}=\frac{\partial {\mathbf {x}}_{\mathrm{s}}}{\partial t}\) represents the velocity of a material point currently at the interface, and \(\mathbf {F}=\frac{\partial {\mathbf {x}}_{\mathrm{s}}}{\partial {\mathbf {X}}_{\mathrm{S}}}\) is the instantaneous deformation gradient at the spatial location \({\mathbf {x}}_{\mathrm{s}}\) with its corresponding reference location \({\mathbf {X}}_{\mathrm{S}}\). The subscripts on \({\mathbf {x}}_{\mathrm{s}}\) and \({\mathbf {X}}_{\mathrm{S}}\) in the definition of \(\mathbf {F}\) serve to remind the fact that these material points currently reside on the interface, but are free to change in any direction. The second term represents the contribution due to interfacial motion in the reference configuration, since by Eq. (107), \({\mathbf {V}}_{\mathrm{S}}=\frac{\mathrm{d} {\mathbf {X}}_{\mathrm{S}}}{\mathrm{d}t}\) is the velocity of the interface in the reference configuration. Thus, the difference between the velocity of the interface and the velocity of a particle currently at the interface is,

The inverse relationship is thus,

where \(\mathbf {G}=\mathbf {F}^{-1}=\frac{\partial {\mathbf {X}}_{\mathrm{S}}}{\partial {\mathbf {x}}_{\mathrm{s}}}\) is the inverse of the deformation gradient at a point on the interface. Furthermore, for a coherent interface, in both the reference and current configurations, at all times, the following conditions must be satisfied

This gives a relation for the jump in the bulk velocity across the interface,

where we have used  . Although not done in the present paper, the above condition is sometimes further reduced by assuming that the deformation gradient jump is nonzero only in the normal direction [13]. That is,

. Although not done in the present paper, the above condition is sometimes further reduced by assuming that the deformation gradient jump is nonzero only in the normal direction [13]. That is,

where \(V_{{\mathrm{S}}_{\mathrm{N}}}\) is the normal component of the reference interface velocity, \(V_{{\mathrm{S}}_{\mathrm{N}}}= \mathbf {N}\cdot {\mathbf {V}}_{\mathrm{S}}\), and \({\mathbf {V}}_{{\mathbf{S}}_{\mathbf{T}}}\) is the tangential component of the reference interface velocity.

The surface gradient and surface divergence of the interface velocity are next derived. Applying the surface gradient operation on Eq. (109), we get

Observing that \(\frac{\partial }{\partial {\mathbf {X}}_{\mathrm{S}}}\left( \frac{\partial {\mathbf {x}}_{\mathrm{s}}}{\partial t}\right) =\frac{\partial }{\partial t}\left( \frac{\partial {\mathbf {x}}_{\mathrm{s}}}{\partial {\mathbf {X}}_{\mathrm{S}}}\right) \), the above expression can be rewritten as

where \(\overset{\triangle }{\mathbf {F}}\) is the convected time derivative of the deformation gradient

Finally, using the above derivation, it is easy to show that

Derivation for the jump in stress–velocity term

Using Eq. (109), we write the stress–velocity jump term as

Denoting the average \( \left\langle \left\langle \mathbf {\cdot } \right\rangle \right\rangle = \frac{1}{2}(\mathbf {\cdot _{-}} +\mathbf {\cdot _{+}})\), the following product relationship may be derived:  . Thus,

. Thus,

where we have used Eqs. (23) and (111). Thus, using Eq. (93), and substituting Eqs. (120) into (119), we get:

Derivation of the second law condition in the reference configuration

Writing \(\left( \mathbf {v}_{\mathrm{s}}-\mathbf {v}\right) =\mathbf {F}{\mathbf {V}}_{\mathrm{S}}\), the second law condition Eq. (37) can be rewritten as,

Nanson’s formula [38] is now used to relate the differential surfaces in current and reference configurations,

where \(J=det(\mathbf {F})>0\) is the Jacobian or the determinant of the deformation gradient \(\mathbf {F}\), \(\mathbf {G}=\mathbf {F}^{-1}=\frac{\partial \mathbf {X}}{\partial \mathbf {x}}\) is the inverse of the deformation gradient, and \(\mathbf {N}\) is the normal to the interface in the reference configuration. By the definition of the first Piola–Kirchhoff stress tensor,

leading to the expression

Thus, expressing the integral in Eq. (122) in the reference configuration, and using the fact that \({\varGamma }_{ {\mathrm{s}}_0}\) is arbitrary, we get the second law condition in reference configuration as

Using the fact that the deformation gradient \(\mathbf {F}=\frac{\partial \mathbf {x}}{\partial \mathbf {X}}=\mathbf {I}+\nabla _0 \mathbf {U}^{\mathrm{T}}\) we can express the above condition in the following alternative form,

where we have used the fact that \(\rho _0=J\rho \). \(\mathbf {\Sigma }_0= \rho _0\psi _0\mathbf {I} - \nabla _0 \mathbf {U}\mathbf {{\varvec{\mathbf {\varvec{\sigma }}}}_{\mathrm{I}}}\) is the Eshelby energy–momentum tensor [39] in the reference configuration.

Rights and permissions

About this article

Cite this article

Vaitheeswaran, P., Udupa, A., Sadasiva, S. et al. Interface balance laws, phase growth and nucleation conditions for multiphase solids with inhomogeneous surface stress. Continuum Mech. Thermodyn. 32, 987–1010 (2020). https://doi.org/10.1007/s00161-019-00804-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00161-019-00804-z