Abstract

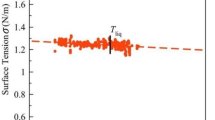

The simulation of casting processes demands accurate information on the thermophysical properties of the alloy; however, such information is scarce in the literature for multicomponent alloys. Generally, metallic alloys applied in industry have more than three solute components. In the present study, a general solution of Butler’s formulation for surface tension is presented for multicomponent alloys and is applied in quaternary Al–Cu–Si–Fe alloys, thus permitting the Gibbs–Thomson coefficient to be determined. Such coefficient is a determining factor to the reliability of predictions furnished by microstructure growth models and by numerical computations of solidification thermal parameters, which will depend on the thermophysical properties assumed in the calculations. The Gibbs–Thomson coefficient for ternary and quaternary alloys is seldom reported in the literature. A numerical model based on Powell’s hybrid algorithm and a finite difference Jacobian approximation has been coupled to a Thermo-Calc TCAPI interface to assess the excess Gibbs energy of the liquid phase, permitting liquidus temperature, latent heat, alloy density, surface tension and Gibbs–Thomson coefficient for Al–Cu–Si–Fe hypoeutectic alloys to be calculated, as an example of calculation capabilities for multicomponent alloys of the proposed method. The computed results are compared with thermophysical properties of binary Al–Cu and ternary Al–Cu–Si alloys found in the literature and presented as a function of the Cu solute composition.

Similar content being viewed by others

References

Perez, M.: Gibbs–Thomson effects in phase transformations. Scr. Mater. 52, 709–712 (2005)

Zinn, T., Willner, L., Lund, R.: Nanoscopic confinement through self-assembly: crystallization within micellar cores exhibits simple Gibbs–Thomson behavior. Phys. Rev. Lett. 113(238305), 238305 (2014)

Bouchard, D., Kirkaldy, J.S.: Prediction of dendrite arm spacings in unsteady and steady-state heat flow of unidirectionally solidified binary alloys. Metall. Mater. Trans. B 28B, 651–663 (1997)

Hunt, J.D., Lu, S.Z.: Numerical modeling of cellular/dendritic array growth: spacing and structure predictions. Metall. Mater. Trans. A 27, 611–623 (1996)

Rappaz, M., Boettinger, W.J.: On dendritic solidification of multicomponent alloys with unequal liquid diffusion coefficients. Acta Mater. 47, 3205–3219 (1999)

Kurz, W., Fisher, J.D.: Dendrite growth at the limit of stability: tip radius and spacing. Acta Metall. 29, 11–20 (1981)

Trivedi, R.: A comparison of theory and experiments. Metall. Mater. Trans. 15A, 977–982 (1984)

Goulart, P.R., Cruz, K.S., Spinelli, J.E., Ferreira, I.L., Cheung, N., Garcia, A.: Cellular growth during transient directional solidification of hypoeutectic Al–Fe alloys. J. Alloys Compd. 470, 589–599 (2009)

Costa, T.A., Moreira, A.L., Moutinho, D.J., Dias, M., Ferreira, I.L., Spinelli, J.E., Rocha, O.L., Garcia, A.: Growth direction and Si alloying affecting directionally solidified structures of Al–Cu–Si alloys. Mater. Sci. Technol. 31, 1103–1112 (2015)

Gündüz, M., Hunt, J.D.: The measurement of solid-liquid surface energies in the Al–Cu, Al–Si and Pb–Sn systems. Acta Metall. 33, 1651–1672 (1985)

Gündüz, M., Hunt, J.D.: Solid–liquid surface energy in the Al–Mg system. Acta Metall. 37, 1839–1845 (1989)

Marasli, N., Hunt, J.D.: Solid-liquid surface energies in the \(\text{ Al-CuAl }_{2}\), \(\text{ Al-NiAl }_{3}\) and Al–Ti systems. Acta Mater. 44, 1085–1096 (1996)

Keslioglu, K., Marasli, N.: Solid–liquid interfacial energy of the eutectoid \(\beta \) phase in the Al–Zn eutectic system. Mater Sci. Eng. A 369, 294–301 (2004)

Keslioglu, K., Gunduz, M., Kaya, H., Çadirli, E.: Solid–liquid interfacial energy in the Al–Ti system. Mater. Lett. 58, 3067–3073 (2004)

Aksöz, S., Ocak, Y., Marasli, N., Keslioglu, K.: Dependency of the thermal and electrical conductivity on the temperature and composition of Cu in the Al based Al–Cu alloys. Exp. Therm. Fluid Sci. 35, 395–404 (2011)

Butler, J.A.V.: The thermodynamics of the surfaces of solutions. Proc. R. Soc. A 135, 348–375 (1932)

Speiser, R., Poirier, D.R., Yeum, K.S.: Surface tension of binary liquid alloys. Scr. Metall. 21, 68–692 (1987)

Yeum, K.S., Speiser, R., Poirier, D.R.: Estimation of the surface tensions of binary liquid alloys. Metall. Trans. 20B, 693–703 (1989)

Picha, R., Vrestal, J., Kroupa, A.: Prediction of alloy surface tension using a thermodynamic database. CALPHAD 28, 141–146 (2004)

Brillo, J., Egry, I., Matsushita, T.: Density and surface tension of liquid ternary Ni–Cu–Fe alloys. Int. J. Thermophys. 27, 1778–1791 (2006)

Tanaka, T., Lida, T.: Application of a thermodynamic database to the calculation of surface. Tension for iron-base liquid alloys. Steel Res. 65, 21–28 (1994)

Miettinen, J.: Thermodynamic–kinetic model for the simulation of solidification in binary copper alloys and calculation of thermophysical properties. Comput. Mater. Sci. 36, 367–380 (2006)

Jácome, P.A.D., Landim, M.C., Garcia, A., Furtado, A.F., Ferreira, I.L.: The application of computational thermodynamics and a numerical model for the determination of surface tension and Gibbs–Thomson coefficient of aluminum based alloys. Thermochim. Acta 523, 142–149 (2011)

Jácome, P.A.D., Moutinho, D.J., Gomes, L.G., Garcia, A., Ferreira, A.F., Ferreira, I.L.: The application of computational thermodynamics for the determination of surface tension and Gibbs–Thomson coefficient of aluminum ternary alloys. Mater. Sci. Forum 730–732, 871–876 (2013)

Hoar, T.P., Melford, D.A.: The surface tension of binary liquid mixtures: lead + tin and lead + indium alloys. Trans. Faraday Soc. 53, 315–326 (1957)

Gasior, W., Moser, Z., Pstrus, J., Krzyzak, B., Fitzner, K.: Surface tension and thermodynamic properties of liquid Ag–Bi solutions. J. Phase Equilib. 24, 40–49 (2003)

Tanaka, T., Hack, K., Lida, T., Hara, S.: Application of thermodynamic databases to the evaluation of surface tension of molten alloys, salt mixture and oxide mixtures. Z. Metallkd. 87, 380–389 (1996)

Tanaka, T., Hack, K., Hara, S.: Use of thermodynamic data to determine surface tension and viscosity of metallic alloys. MRS Bull. 24, 45–51 (1999)

Kasama, A., Inui, T., Morita, Z.: Measurements of surface tension of liquid Ag–Au and Cu–(Fe, Co, Ni) binary alloys. Jpn. Inst. Met. 42, 1206–1212 (1978)

Hajra, J.P., Lee, H.K., Frohberg, M.G.Z.: Calculation of surface tension of liquid binary systems from the data of the pure components and the thermodynamic infinite dilution values. Z. Metallkde. 82, 603–608 (1991)

Hajra, J.P., Frohberg, M.G.Z., Lee, H.K.: Calculation of surface tension of liquid binary systems from the data of the pure components and the thermodynamic infinite dilution values. Z. Metallkde. 82, 603–608 (1991)

Lee, H.K., Hajra, J.P., Frohberg, M.G.Z.: Calculation of the surface tensions in liquid ternary metallic systems. Z. Metallkde. 83, 638–643 (1992)

Lee, H.K., Frohberg, M.G.Z., Hajra, J.P.: The determination of the surface tensions of liquid iron, nickel and iron–nickel alloys using the electromagnetic oscillating droplet technique. Steel Res. 64, 191–196 (1993)

Tanaka, T., Kitamura, T.: Evaluation of surface tension of molten ionic mixtures, I. A. Back. ISIJ Int. 46, 400–406 (2006)

Nascimento, F.C., Paresque, M.C.C., de Castro, J.A., Jácome, P.A.D., Garcia, A., Ferreira, I.L.: Application of computational thermodynamics to the determination of thermophysical properties as a function of temperature for multicomponent Al-based alloys. Thermochim. Acta 619, 1–7 (2015)

Jácome, P.A.D., Fernandes, M.T., Garcia, A., Ferreira, A.F., Castro, J.A., Ferreira, I.L.: Application of computational thermodynamics to the evolution of surface tension and Gibbs–Thomson Coefficient during multicomponent aluminum alloy solidification. Mater. Sci. Forum 869, 416–422 (2016)

Author information

Authors and Affiliations

Corresponding author

Additional information

Communicated by Andreas Öchsner.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ferreira, D.J.S., Bezerra, B.N., Collyer, M.N. et al. The use of computational thermodynamics for the determination of surface tension and Gibbs–Thomson coefficient of multicomponent alloys. Continuum Mech. Thermodyn. 30, 1145–1154 (2018). https://doi.org/10.1007/s00161-018-0670-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00161-018-0670-6