Abstract

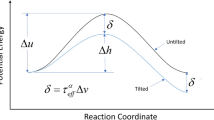

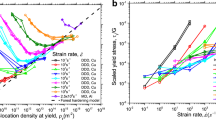

Posed within the two-temperature theory of non-equilibrium thermodynamics, we propose a model for thermoviscoplastic deformation in metals. We incorporate the dynamics of dislocation densities–mobile and forest—that play the role of internal state variables in the formulation. The description based on two temperatures appears naturally when one recognizes that the thermodynamic system undergoing viscoplastic deformation is composed of two weakly interacting subsystems, viz. a kinetic-vibrational subsystem of the vibrating atomic lattices and a configurational subsystem of the slower degrees of freedom relating to defect motion, each with its own temperature. Starting with a basic model that involves only homogeneous deformation, a three-dimensional model for inhomogeneous viscoplasticity applicable to finite deformation is charted out in an overstress driven viscoplastic deformation framework. The model shows how the coupled evolutions of mobile and forest dislocation densities, which are critically influenced by the dynamics of configurational temperature, govern the strength and ductility of the metal. Unlike most contemporary models, the current proposal also affords a prediction of certain finer details as observed in the experimental data on stress–strain behaviour of metals and this in turn enhances the understanding of the evolving and interacting dislocation densities.

Graphical Abstract

Similar content being viewed by others

References

Cheng, F., Kim, S., Reddy, J.: Computational modeling of the plastic-damage behavior of porous max phase with aligned ellipsoid-like pores under uniaxial compression. Int. J. Solids Struct. 63, 121–138 (2015)

Chowdhury, S.R., Kar, G., Roy, D., Reddy, J.: Two-temperature thermodynamics for metal viscoplasticity: continuum modeling and numerical experiments. J. Appl. Mech. 84(1), 011002 (2017a)

Chowdhury, S.R., Roy, D., Reddy, J.: Relating entropy flux with heat flux in two-temperature thermodynamic model for metal thermoviscoplasticity. J. Appl. Mech. 84(2), 021007 (2017b)

Chowdhury, S.R., Roy, D., Reddy, J., Srinivasa, A.: Fluctuation relation based continuum model for thermoviscoplasticity in metals. J. Mech. Phys. Solids 96, 353–368 (2016)

Coleman, B.D., Noll, W.: The thermodynamics of elastic materials with heat conduction and viscosity. Arch. Ration. Mech. Anal. 13(1), 167–178 (1963)

Edelen, D.G.: On the existence of symmetry relations and dissipation potentials. Arch. Ration. Mech. Anal. 51(3), 218–227 (1973)

Edelen, D.G.: Applied Exterior Calculus. Courier Corporation, North Chelmsford (2005)

Estrin, Y.: Dislocation-density-related constitutive modeling. Unified Const. Laws Plast. Deform. 1, 69–106 (1996)

Hoge, K., Mukherjee, A.: The temperature and strain rate dependence of the flow stress of tantalum. J. Mater. Sci. 12(8), 1666–1672 (1977)

Jia, D., Ramesh, K., Ma, E., Lu, L., Lu, K.: Compressive behavior of an electrodeposited nanostructured copper at quasistatic and high strain rates. Scr. Mater. 45(5), 613–620 (2001)

Kamrin, K., Bouchbinder, E.: Two-temperature continuum thermomechanics of deforming amorphous solids. J. Mech. Phys. Solids 73, 269–288 (2014)

Kubin, L., Estrin, Y.: Evolution of dislocation densities and the critical conditions for the portevin-le chatelier effect. Acta Metallurgica et Materialia 38(5), 697–708 (1990)

Langer, J., Bouchbinder, E., Lookman, T.: Thermodynamic theory of dislocation-mediated plasticity. Acta Mater. 58(10), 3718–3732 (2010)

Langer, J.S.: Statistical thermodynamics of strain hardening in polycrystalline solids. Phys. Rev. E 92(3), 032125 (2015)

Milošević, N., Vuković, G., Pavičić, D., Maglić, K.: Thermal properties of tantalum between 300 and 2300 k. Int. J. Thermophys. 20(4), 1129–1136 (1999)

Nemat-Nasser, S., Guo, W.: Flow stress of commercially pure niobium over a broad range of temperatures and strain rates. Mater. Sci. Eng. A 284(1), 202–210 (2000)

Nemat-Nasser, S., Guo, W.-G.: Thermomechanical response of hsla-65 steel plates: experiments and modeling. Mech. Mater. 37(2), 379–405 (2005)

Nemat-Nasser, S., Isaacs, J.: Direct measurement of isothermal flow stress of metals at elevated temperatures and high strain rates with application to Ta and TaW alloys. Acta Mater. 45(3), 907–919 (1997)

Shabalin, I.L.: Ultra-High Temperature Materials I: Carbon (Graphene/Graphite) and Refractory Metals. Springer, Berlin (2014)

Author information

Authors and Affiliations

Corresponding author

Additional information

Communicated by Andreas Öchsner.

Rights and permissions

About this article

Cite this article

Roy Chowdhury, S., Kar, G., Roy, D. et al. Metal viscoplasticity with two-temperature thermodynamics and two dislocation densities. Continuum Mech. Thermodyn. 30, 397–420 (2018). https://doi.org/10.1007/s00161-017-0606-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00161-017-0606-6