Abstract

An approximate thickness optimization of a rectangular Kirchhoff-Love plate with variable stiffness under uniform load is performed in this paper. The authors propose an original method for formulating problems of optimal design for plate structures of variable thickness. Partial discretization, which is described in this paper, reduces the number of independent variables in the problem formulation to only one, making the problem possible to solve via application of the Pontryagin’s minimum principle. The optimization problem relates to the search for the optimal plate thickness distributions, which provides the minimum structural volume of the material used while simultaneously meeting all constraint conditions. The optimal design task is formulated as a control theory problem, maintaining the formal structure of the minimum principle, and then is transformed into a two-point boundary value problem. Such an approximate solution, meeting all necessary optimality conditions, is found by using Dircol software for a chosen illustrative example.

Similar content being viewed by others

1 Introduction

Shape optimization is a fundamental concept of any structural design process in civil engineering—the process whose main goal is to minimize the total cost of construction. Despite this, shape optimization in civil engineering is commonly performed only in the most basic form, namely via the process of “dimensioning”: finding the minimal size of a single or at most of few geometric properties of a structural element of an assumed shape. The shape itself is usually given, a priori, in the architectural guidelines, or it is strongly constrained by the available solutions: steel sections, formwork elements, etc. In fact, any attempt to minimize the cost for the erection of a structure must take into account the fact that those easily available solutions are also the least expensive ones—the performance of a hot-rolled steel beam of custom cross-section or the performance of a custom curvilinear formwork increase the cost of construction considerably, due to their unitary (non-serial) character.

Another reason for which shape optimization methods are not commonly used in civil engineering is the complexity of the mathematical modeling required. The need to take into account all constraints arising from standards and those constraints additionally imposed by developers, as well as many decision variables and many load combinations, significantly increase the dimensions of the optimization problems. The optimization methods, which may make it possible to solve such complex shape optimization tasks, are methods based on the optimal control theory.

Most of the optimal control problems in engineering are related to the optimization of processes for which the independent variable is time (Geering 2007). The use of the control theory in problems related to the optimal design of one-dimensional structural elements became possible thanks to the analogy in the form of equations defining processes and equations defining structural elements. The formulation of the structural element optimization tasks within the formalism of the Pontryagin minimum principle (Pontryagin et al. 1962) was possible, in particular, as a result of adopting an independent variable, namely, the coordinate measured along a bar geometric axis, rather than time.

Various problems in the optimal design of one-dimensional bar systems have been solved in recent years, including, inter alia, those problems concerning the optimization of steel, composite, or wooden multi-span girders (Laskowski and Mikulski 2009; Kropiowska 2016), reinforced concrete or steel frames (Laskowski 2017) and arches (Mikulski 2004); the tasks of optimal shaping of spatially-loaded, thin-walled beams (Kropiowska 2016) and many more.

The methods of the optimal control in problems in which both system of governing equations, as well as the control, depend on a single variable are understood and developed to a much greater extent and are much easier in application than in the case of multidimensional problems governed by partial differential equations. Some examples of procedures for solving optimal control problems of dynamical systems governed by partial differential equations were presented by Pesch (2012). The task of optimal design of a plate structure is also an example of a multidimensional problem. The lack of analysis of thickness optimizations of a fundamental structural element such as a plane thin rectangular plate is clearly visible.

Some early work on the optimal design of plates with piecewise constant thickness can be found in (Szefer and Demkowicz 1984; Salupere 1992). More papers were published addressing the problem of the minimum cost design of concrete, reinforced concrete, or prestressed concrete slabs (see Ghandi et al. 2017; El Semelawy et al. 2012; Ahmadi-Nedushan and Varaee 2011; Ahmadkhanlou and Adeli 2005). These papers are related to the search for discrete design variables, such as the thickness of a slab, steel bar diameter, or bar spacing; the optimal thickness obtained as a result of numerical calculations was constant over the entire plate. Additional issues were related to the search for the optimal dimensions of flat slab buildings using a genetic algorithm and a hybrid optimization algorithm (see Sahab et al. 2005). The optimal design of a plate with variable thickness was studied in the paper by Pedregal and Donoso (2003)—the one-dimensional model was analyzed to optimize the plate, which was assumed to be infinite along one of its axes. Several problems concerning topology optimization of plate structures with reference to the volume minimization were discussed in (Goo et al. 2016). The topology optimization, which is one of the most popular structural optimization methods, was also used in those works concerning the optimization of plates (see Bruggi and Taliercio 2015; Long et al. 2009). Examples of the optimal design of plates under dynamic loads were presented by Falco et al. (2004), where a sequential quadratic programming algorithm was used to solve the shape optimization problem.

However, it can be observed, that a large majority of the research works linked to plate thickness optimization are related to the search for an optimal value of constant thickness or optimal piecewise constant thickness. There is still a lack of research regarding plate optimization problems that account for many constraints, especially in problems that are searching for the optimal thickness distribution, which is variable over the plate.

The thickness optimization of plates, especially when taking into account the number of constraint conditions, is a topic that still needs to be researched. Such research is even more important as plane plates are indispensable structural elements in most modern buildings—house, offices, and commercial-entertainment centers with plate-wall or plate-column structural systems. It is also one of the most material-consuming, thus a cost-generating element of a structure. Thickness optimization of plates may be of particular importance in the case of the design of serially manufactured prefabricated plates, e.g., metal sheet segments produced in the process of stamping.

The goal of this paper is to develop a simplified, approximate method of thickness optimization of rectangular Kirchhoff-Love plates, to perform such an optimization for given illustrative examples, and to discuss certain aspects of the analyzed problem, as well as of the introduced method and obtained results. The simplification of the optimization problem via its partial discretization enables the solving of it by using methods dedicated to one-dimensional problems. Among such methods, the Pontryagin’s minimum principle emerges as a useful tool with a wide scope of possible applications. In recent years, the minimum principle has been given a solid numerical basis (von Stryk 2000), which provides the possibility of finding solutions to complex optimization tasks. For this reason, it was chosen as a solution method for the computation presented in this paper. Numerical calculations were carried out by using Dircol software (von Stryk 2002).

2 Formal statement of a general problem

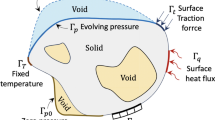

We consider a flat, thin elastic plate of rectangular shape, made of a homogeneous isotropic material, subjected to its own weight and a continuous load q perpendicular to a middle plane (Fig. 1).

The governing equation for the Kirchhoff-Love plate of variable thickness is a two-dimensional, non-homogeneous fourth-order linear partial differential equation of the following form (Timoshenko and Woinowsky-Krieger 1959):

where w (x, y) is the deflection of a point (x, y) of the plate, P (x, y) is a load described by (2), including the continuous load q and the self-weight, H (x, y) is the plate thickness distribution, and D (x, y) is the plate flexural stiffness distribution defined by relation (3).

The material data γ, E, and v are the specific weight, Young’s modulus, and the Poisson ratio, respectively, all of which are constant within the plate.

The edge supports provide the appropriate boundary conditions. The thickness, in every point of the plate, must be chosen in such a way that the maximum normal stress in each point does not exceed a certain fixed limit value σ0. This provides the inequality constraints of the form:

The inequality constraints on maximum normal stress is only for the sake of definiteness; in true design problem, also the shear stress should be limited to a certain value respective of the chosen limit state hypothesis. Both constraints may be accounted for by a choice of certain limit state criterion (e.g., Huber-Mises, Tresca) and imposing an inequality constraint for an “equivalent stress” respective for that criterion. This, however, requires a line search of maximum equivalent stress along z-coordinate in every (x;y) point. In order to simplify the task our considerations are restricted to limiting the normal stress only.

The optimization problem under consideration relates to the search for optimal plate thickness distributions, which provides the minimum structural volume V of the material used and simultaneously meets all of the constraint conditions. As the flexural stiffness is a one-to-one function of the plate thickness, it may be equivalently considered as a control. The control is constrained to take values from a given interval. The plate thickness, the load, and the total volume V may be expressed by the flexural stiffness, respectively:

3 Statement of the optimization problem of an approximate discretized system

3.1 Partial discretization

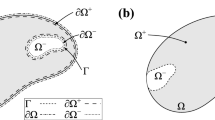

The idea of discretization of a two-dimensional system to a single-dimensional one was used, for example in Liepelt and Schittkowski (2001). In order to simplify the problem, namely to approximate it with a one-dimensional system, a partial discretization is performed. One of the independent spatial variables—let’s say the x variable—remains a continuous set, while the second one is replaced by a finite set of fixed values of variable y:

where

The two-dimensional area of the rectangular plate is thus replaced with strips with constant width Δy formed by the lines parallel to the x axis (Fig. 2).

We introduce a set of functions wi(x), Di(x) for every i = 1, 2, …, N, determining the distribution of deflection and flexural stiffness, respectively, along the line {(x, y) : 0 ≤ x ≤ Lx ∧ y = yi} for a given i.

A two-dimensional system, described by a single partial differential equation (PDE) (1), may be now replaced with a finite set of one-dimensional systems, coupled with a system of ordinary differential equations (ODE). In the governing (1), any differential operator involving differentiation with respect to the discretized variable must be replaced by an appropriate finite difference (FD) operator. The 2nd-order precision finite difference operators were chosen:

where fi and \( {\left.\frac{\partial^nf}{\partial {y}^n}\right|}_i \) denote chosen function along the i-th line y = yi and its n-th derivative, with respect to the y variable, respectively. The use of higher precision operators requires introduction of greater number of fictitious (out-of-domain) state variables in order to write down finite differences, as it is described below.

3.2 State equations of one-dimensional approximate system

Now, we introduce the following state variables for every i = 1, 2, …, N:

The set of N control variables is assumed:

The discretized system is governed by the following system of 6 N first order ODE:

where the derivative \( {\left({X}_i^{(4)}\right)}^{\prime } \) is determined by formula (1), thus satisfying relation (11).

The differential operators in (11) are replaced by the appropriate finite difference operators, which leads to the obtaining of the following expression for Fi:

In order to write down finite difference schemes in the above relation, one should also introduce fictitious state variables \( {X}_{-1}^{(1)},{X}_0^{(1)},{X}_0^{(2)},{X}_0^{(3)},{X}_{N+1}^{(1)},{X}_{N+1}^{(2)},{X}_{N+1}^{(3)},{X}_{N+2}^{(1)} \).

These functions are determined by using boundary conditions, as described below.

3.3 Boundary conditions

The edge supports provide appropriate boundary conditions on the state variables. We narrow our considerations to plates with no free edges. We will distinguish the boundaries along the axis of the discretized coordinate from the continuous one.

In the case of the first ones, we obtain for x0 = 0 or x0 = Lx:

where the bending moments are expressed in terms of the introduced state variables:

The supports at the edges parallel to the non-discretized coordinate provide additional relations, enabling us to write the finite differences mentioned above, by determining fictitious state variables \( {X}_{-1}^{(1)},{X}_0^{(1)},{X}_{N+1}^{(1)},{X}_{N+2}^{(1)} \), namely:

Additional boundary conditions must be defined for \( {X}_i^{(5)},{X}_i^{(6)} \) (i = 0, 1, 2, ..., N + 1), which are interpreted as the distribution of flexural stiffness along the line y = yi and its derivative, respectively. Their boundary values are to be found. If we narrow our considerations to a class of problems characterized by the existence of two symmetry axes, parallel to the axes of the chosen coordinate system, the boundary conditions for the functions in this discussion may be written as follows:

In the case of plates with two planes of symmetry, where one plane is perpendicular and the other is parallel to the discretized direction, one may obviously make use of symmetry in formulating the problem. Considering the plane of symmetry perpendicular to the discretized direction it may be done by substituting (or equating) every state variable with the one respective due to the symmetry. The other plane of symmetry (with respect to (y;z) plane) may also be taken into account in formulating the proper boundary conditions in the middle of the span by imposing zero boundary conditions on angle of a deflection and third derivative of a deflection. This would automatically provide us with solution of proper symmetry.

3.4 Inequality constraints

The desired optimal solution must satisfy two sets of inequality constraints. The first one is determined by the minimum and maximum permissible thicknesses of the plate, which is equivalent to:

where:

The second set of inequality constraints follows by constraining the maximum normal stress to the limit value:

The normal stresses are determined in accordance with (4) and can be expressed as follows:

3.5 Optimization of plate in the minimum principle formal structure

Solving the aforementioned problem is possible by using calculus of variations, Euler-Lagrange differential equations, and the minimum principle (Pesch and Bulirsch 1994). The Pontryagin minimum principle makes it possible to establish the necessary optimality conditions of the task under discussion. Each optimal control task is presented as a multi-point boundary value problem, which can only be solved numerically.

The optimization problem, formulated in the category of the control theory, must have a strictly defined formal structure, which will allow the minimum principle to be applied. The basic elements of this structure are state equations with boundary conditions, constraints, and the objective function. The problem of the plate optimal shaping was solved numerically by using the direct collocation method, implemented in Dircol (A Direct Collocation Method for the Numerical Solution of Optimal Control Problems), developed by Oskar von Stryk (von Stryk 2002). This program is one of the few that allows for the solving of complex optimal control tasks with significant dimensions. The accuracy of the solutions obtained via Dircol and the operation of the program have been previously verified in numerous optimization tasks by comparing the results with solutions obtained by other methods. The numerical calculations provide a control which satisfies a necessary condition for being optimal; thus, among all controls found, one should look for a global extremum by comparing the respective values of the objective function.

4 Numerical example

A numerical solution was found for the chosen example. Our considerations were narrowed to the special case of a square plate, which enables the direct verification of the proposed method’s accuracy. The plate dimensions are Lx = 2 m, Ly = 2 m, and it is made of material characterized by the constants E = 15GPa, γ = 20kN/m3, ν = 0.15. The plate was simply-supported at its circumference.

An external load was assumed to be q = 100 kPa. This data was chosen in order to verify the obtained results with a benchmark example discussed in (Radwańska 2009).

We incorporated the symmetry perpendicular to the discretized direction in our example, and the half system could be considered in the analysis (Fig. 3). This symmetry is satisfied by substitution of proper state variables as described above. The discretization was performed for N = 10, thus the strip width is Δy = 0.1m.

4.1 Optimization task structure

The optimization problem can be defined as the search for the optimal thickness distributions that minimizes the assumed objective function, while satisfying all constraint conditions.

4.1.1 State and control variables

In general, sixty state variables were defined—six state variables for each i = 1, 2, …, 10, respectively. They are listed in Table 1.

The second derivatives of the flexural stiffness functions were assumed to be control variables:

Defining the set of ten control variables in the form (25) allows us to determine the optimal thickness distributions Hi (22) for each i = 1, 2,…,10, as the flexural stiffness is a one-to-one function of the plate thickness. The problem was eventually defined by the system of 60 state equations in accordance with (10) and (12).

4.1.2 Objective function

The volume minimization was assumed to be an optimization criterion. The total volume of the plate may be expressed as follows:

where

The additional state variable (28) and 61 state equation (29) was introduced:

The optimization problem of the Lagrange functional in the form:

was transformed, thanks to the introduction of the state (29), into a Mayer problem with functional (31) and initial condition (32):

where:

- X(x), U(x):

-

the vector of state variables and control variables, respectively.

4.1.3 Boundary conditions

All boundary conditions were defined as explicit conditions. The explicit conditions of the first order define the initial and final value of state variables. The boundary conditions for the state variables \( {X}_i^{(1)},{X}_i^{(2)},{X}_i^{(3)} \) result from the way that the plate is supported (for simply supported edges—see Section 3.3). For the bisymmetric plate, additional boundary conditions were defined for the state variables \( {X}_i^{(5)},{X}_i^{(6)} \):

The plate thickness, at all simply supported edges was assumed to be constant and equal to 7.5 cm: H0 = Hi(0) = Hi(Lx) = 0.075m for i = 1, 2, …, 10. Thus, the proper value of the flexural stiffness was determined.

4.1.4 Constraints

For the task under discussion, ten inequality constraint conditions were implemented. The inequality-type conditions result from the limits of normal stresses:

The normal stresses were determined in accordance with (24) and the limit value was assumed to be σ0 = 12.5MPa. In addition, constraints for the courses of thickness distribution were imposed:

where Hmin = 0.05m, Hmax = 0.15m. On the basis of these values, appropriate constraints for the courses of flexural stiffness distribution were assumed.

4.2 Optimal solution and numerical results

The optimal controls were determined in accordance with the Pontryagin minimum principle. The Hamilton function and the adjoint equations for the discussed problem were defined. The boundary conditions for the adjoint variables result from the transversality conditions. Because of the irregularity of the Hamilton function, which results from its linear dependency on the control variables, it is necessary to produce constraints on the controls, in the form of:

Then, after introducing the switching function Si (37), the optimal controls are defined in accordance with (38) valid within the intervals for which no constraints are active, namely, gi > 0.

In the case of the occurrence of the intervals [xS1, xS2], in which Si = 0, a singular control is determined. If there are no intervals [xS1, xS2] and the switching function Si takes the zero value only at isolated switching points, then the control starts to \bang at switching points between the values of Ui, min, Ui, max and bang-bang control is determined.

All ten constraints gi are constraints only for state variables and there is no explicit dependency of constraints on the control variables. The order of all constraints is equal to 2, because the controls occur in the explicit form in the second derivative of the constraint functions.

The optimal control task was transformed into a two-point boundary value problem. A total of 244 values were determined for the optimization task, namely: 61 state variables, 61 adjoint variables, 10 control variables, 10 Lagrange multipliers relating to state variable constraints, 51 constants responsible for the bangs of state variables at supporting points, and 51 constants responsible for the bangs of adjoint variables at supporting points. The two-point boundary value problem was solved numerically by means of the Dircol 2.1 program. The calculation results were obtained as a set of data and in a graphic form, as diagrams. As a result of the calculations performed, a solution meeting all necessary optimality conditions was found, where the value of the objective function (namely, the volume of material) was V = 34.386 ⋅ 10−2m3(Fig. 4). Comparing the volume obtained for the optimally shaped plate with that value obtained for the plate with a constant thickness: H = 0.1 m (V = 40 ⋅ 10−2m3), it can be seen that the value of the objective function has been reduced by approximately 14%. The shaping of the plate with constant thickness H = 0.09 m would result in stresses that exceed the allowable values.

Computational effort for finding an optimal solution to a single problem was relatively large as it depends on numerous factors. Finding the correct initial values for all state variables and control variables was the most time-consuming part of computation for our task. Expertise with respect to the system’s behavior was thus required. Finding the optimal solution meeting all necessary conditions, required several runs of the program to be made. However, for given initial data, the computation itself is performed quickly, within seconds up to minutes.

The Hamilton function for the problem under discussion is constant, and all conditions for the adjoint variables resulting from the transversality conditions are met. This additionally confirms the correctness of the obtained results.

The optimal distributions of the control variables providing the minimization of the plate volume were obtained. The controls assumed values from the boundary of the allowable area, and also singular solutions were found. The optimal controls structure is shown in Table 2.

For the constraints gi, which were defined in accordance with the formula (34), boundary intervals of constraint activities may occur. For the problem under consideration, the constraint g10 is active in the boundary interval x ∈ [0.65, 1.35m], as shown in Fig. 5.

The optimal distributions of control variables with corresponding thickness distributions are presented in Fig. 6.

It is worth noting that for the control, which is piecewise constant-valued, its second anti-derivative (flexural stiffness distribution) is given by a second degree spline. Based on the obtained diagrams of thickness functions (Fig. 5), it is possible to determine the distributions of thickness for the entire plate structure (Figs. 7 and 8).

The trajectories of all 61 state variables and corresponding adjoint variables were obtained. Figure 9 shows the diagrams of the set of state variables for the line i = 10.

The selection of the square plate for the illustrative example was intentional, because this allows us to additionally verify the accuracy of the obtained solutions. To this end, results received in the center section of the plate were compared, for instance continuous solutions for y = 1 m with the discrete ones for x = 1 m. Diagrams of the deflections, bending moments, and plate thickness distributions from two directions are presented in Figs. 10, 11, and 12, respectively. As it can be observed, the presented method is effective for the regular area of the rectangular plate. The discrete solutions approximate the respective continuous solutions properly. Slightly greater differences appeared for the plate thickness distributions, but the maximal difference between the continuous and the discrete solutions do not exceed 0.76 mm, which is ca. 1% of plate’s minimum thickness. It is worth adding that the minimum and maximum permissible values of the control variables also impact the course of the plate thickness; thus, expertise with respect to the system’s behaviour is required to select the best possible limit values.

We should also remember that minimum principle provides us only with the necessary conditions for the existence of a local extremum. The continuation of the calculations and the search for other optimal solution candidates will make it possible to select the best solutions with the smallest objective function value. In the considered example, the symmetry conditions are violated only to a small extent which in the authors’ opinion, may be neglected. Therefore, one should expect that a greater density in the discretization grid, as well as better assumptions of limit values may allow for the obtaining of even better solutions.

4.3 Results for various discretization

Basic analysis of influence of density of discretization on obtained results was performed. Optimization of square simply supported plate under uniform load was performed for two more discretizations, namely for the strip width Δy equal 20 cm and 50 cm, respectively, additionally to already presented results obtained for Δy = 10 cm. In Fig. 13 deflection along the central (mid-span) strip is plotted for each discretization. The optimal thickness along the central strip is presented in Fig. 14.

It may be observed that final results are not significantly influenced by the discretization density in case of any finer discretization (Δy = 10 cm or Δy = 20 cm). Any comment on rough discretization (Δy = 50 cm—the same as in chosen FDM benchmark example) must take into account issues concerning poor approximation of both objective function and normal stress determining the inequality constraints. Value of the total structural volume is approximated by the assumption that the value of thickness distribution is constant at width Δy. For large Δy approximation of objective function with piece-wise constant functions makes the objective of optimization far from the desired one. Similarly, normal stress distribution is determined by 2nd-order derivatives along both independent variables. Rough discretization makes the finite difference approximation of derivative ∂2/∂y2 poor, so the stress distribution is also “averaged” (not sensu stricto) as it accounts for influence of distant parts of the structure. As a result, rough discretization underestimates the maximum normal stress in the middle of the span what yields smaller thickness—in particular it may happen to be too small to resist true stress. Smaller thickness results in turn in greater deflection. This smaller thickness is then extrapolated within width Δy, in which optimal thickness distribution would be otherwise smaller than the mid-span value (due to smaller stress values)—it cannot be, however, stated in advance what this reduced value would be comparing to the extrapolated value. Combined averaging of stresses and approximating the objective function with constant-valued strips, which are the consequences of rough discretization, makes the actual objective of optimization unpredictable in the sense that its relation with the original objective is disturbed in an unknown manner.

More precise analysis of the influence of density of discretization on optimization results require computations of much larger scope—accounting for different geometries, non-uniform loads, various boundary conditions etc.

5 Practical application of the method

Despite possible theoretical generalization of the proposed approach, it must be admitted that its practical applicability is obviously limited to plates, the shape of which is any composition of rectangular areas—this includes also plates with openings. Additional rectangular subareas, formed by lines perpendicular to the discretized direction, in general rise the number of state equations. Each rectangular subarea marked with dashed gray line (Fig. 15) requires independent set of state equations.

Despite this limitation, within considered class of problems, proposed method do not impose additional restrictions. In particular, one may consider mixed boundary conditions varying along edges—in case of varying support along non-discretized direction this requires introduction of an additional subarea. In case of supports along discretized direction, mixed boundary conditions are introduced by imposing respective conditions for proper state variables. Supports in the interior of the plate may also be accounted for. The method imposes no limitations on the function of load distribution. Only rapid variety in boundary conditions and load distribution makes the approximate solution more dependent of discretization density as well as of stability and convergence requirement of the finite difference method itself. However, for more regular problems—and this is still the majority of problems, which are dealt with in engineering practice—proposed approach provides a simple method of obtaining an applicable solution to an optimization problem.

In this section, solutions to additional problem of more general geometry (rectangular, non-square plate, different boundary conditions on the edges) were also presented.

We considered a rectangular plate of dimensions: Lx = 2 m, Ly = 3 m with two edges simply-supported and the other two fixed (Fig. 16).

The other data assumed for the calculations (material constants, constraint conditions, load value) were the same as for the previous task. The discretization was performed for N = 10, thus the strip width was currently equal: Δy = 0.15m.

The search was for the optimal thickness distributions that minimized the structural volume of the material used, while satisfying all constraint conditions. All boundary conditions, which were defined as explicit conditions, resulted from the way that the plate was supported.

As a result of numerical calculations performed with use of the Dircol program, solutions meeting the assumed constraints and all necessary optimality conditions were found.

Only the most important results were shown as diagrams. The optimal thickness distribution for the most stressed central line number i = 10 was presented in Fig. 17.

The distributions of thickness for the entire plate structure were shown in Figs. 18, 19, and 20.

The objective function, namely total volume of the optimally shaped plate, was V = 59.437 ⋅ 10−2m3. The structural volume has been reduced by approximately 24%, when comparing with the plate about a minimal constant thickness for which V = 78 ⋅ 10−2m3 .

6 Conclusions

In this paper, the original method for formulating thickness optimization problems of a rectangular Kirchhoff-Love plate with variable stiffness was presented. The objective was to minimize the volume of the material of the optimally shaped plate while simultaneously meeting all constraint conditions. The methodology, which makes the multidimensional problem governed by partial differential equations possible to solve via application of the Pontryagin’s minimum principle was described in detail. The solutions, which meet all necessary optimality conditions, were found for chosen illustrative examples. The proper formulation of the optimization tasks was challenging due to the complexity of the problem and the necessity of searching for singular controls.

The results demonstrate that the optimization method, based on the optimal control theory, may be a promising method in the optimal design of plate structures. Especially on the basis of the presented formulations, calculations for the optimal design in real plate structures, such as flat slabs of buildings, can be performed since the implementation of additional constraints, loads, and other boundary conditions in the analysis is possible. Alternatively, the objective function can be set to minimize maximum stresses or maximum displacements of the plate. An undoubted advantage of this method is obtaining the solutions that depict the complete courses of all control variables, state variables, adjoint variables, and constraint functions.

The presented method proves that the optimal control theory can be successfully used in calculations for plate structures and brings us closer to the practical application of mathematical optimal control methods in structural design.

References

Ahmadi-Nedushan B, Varaee H (2011) Minimum cost design of concrete slabs using particle swarm optimization with time varying acceleration coefficients. World Appl Sci J 13(12):2484–2494

Ahmadkhanlou F, Adeli H (2005) Optimum cost design of reinforced concrete slabs using neural dynamics model. Eng Appl Artif Intell 18(1):65–72

Bruggi M, Taliercio A (2015) Optimal strengthening of concrete plates with unidirectional fiber-reinforcing layers. Int J Solids Struct 67-68:311–325

El Semelawy M, Nassef AO, El Damatty AA (2012) Design of prestressed concrete flat slab using modern heuristic optimization techniques. Expert Syst Appl 39(5):5758–5766

Falco SA, Afonso SMB, Vaz LE (2004) Analysis and optimal design of plates and shells under dynamic loads – II: optimization. Struct Multidiscip Optim 27(3):197–209

Geering HP (2007) Optimal control with engineering applications. Springer-Verlag, Berlin Heidelberg

Ghandi E, Shokrollahi N, Nasrolahi M (2017) Optimum cost design of reinforced concrete slabs using cuckoo search optimization algorithm. Int J Optim Civil Eng 7(4):539–564

Goo S, Wang S, Hyun J, Jung J (2016) Topology optimization of thin plate structures with bending stress constraints. Comput Struct 175:134–143

Kropiowska D (2016) Selected problems of the optimal design of bar systems within the formal structure of the minimum principle. Cracow University of Technology Publishing House, Cracow

Laskowski H (2017) Optimal design of structural elements as a control theory problem. TT 114(6):119–134

Laskowski H, Mikulski L (2009) Control theory in composite structure optimizing. MAM 55(6):346–351

Liepelt M, Schittkowski K (2001) Optimal control of distributed systems with break points. In: Groetschel M, Krumke SO, Rambau J (eds) Online optimization of large scale systems. Springer, pp 271–294

Long CS, Loveday PW, Groenwold AA (2009) Effects of finite element formulation on optimal plate and shell structural topologies. Finite Elem Anal Des 45(11):817–825

Mikulski L (2004) Control structure in optimization problems of bar systems. Int J Appl Math Comput Sci 14(4):515–529

Pedregal P, Donoso A (2003) Optimal design of a plate of variable thickness: a variational approach in dimension one. Comput Appl Math 22(1):75–89

Pesch HJ (2012) Optimal control of dynamical systems governed by partial differential equations: a perspective from real-life applications. IFAC Proc Vol 45(2):1–12

Pesch HJ, Bulirsch R (1994) The maximum principle, Bellman's equation, and Carathéodory's work. J Optim Theory Appl 80(2):199–225

Pontryagin LS, Boltyanskii VG, Gamkrelidze RV, Mishchenko EF (1962) The mathematical theory of optimal processes. Wiley-Interscience, New York

Radwańska M (2009) Ustroje powierzchniowe: podstawy teoretyczne oraz rozwiązania analityczne i numeryczne: podręcznik dla studentów wyższych szkół technicznych. Cracow University of Technology Publishing House, Cracow (in Polish)

Sahab MG, Ashour AF, Toropov VV (2005) Cost optimisation of reinforced concrete flat slab buildings. Eng Struct 27(3):313–322

Salupere A (1992) Optimal design of rigid-plastic annular plates with piecewise constant thickness. Struct Optim 4(3–4):186–192

Szefer G, Demkowicz L (1984) Optimal design of Von Karman plates. J Struct Mech 12(1):111–149

Timoshenko S, Woinowsky-Krieger S (1959) Theory of plates and shells. Mc Graw-Hill, New York

von Stryk O (2000) Numerical hybrid optimal control and related topics. Habilitation dissertation. Technische Universität München

von Stryk O (2002) User’s guide for Dircol (Version 2.1): a direct collocation method for the numerical solution of optimal control problems. Technical report, simulation and systems optimization group. Technische Universität Darmstadt

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible Editor: Fred van Keulen

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Kropiowska, D., Mikulski, L. & Szeptyński, P. Optimal design of a Kirchhoff-Love plate of variable thickness by application of the minimum principle. Struct Multidisc Optim 59, 1581–1598 (2019). https://doi.org/10.1007/s00158-018-2148-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00158-018-2148-3