Abstract

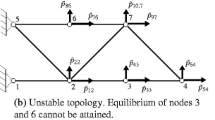

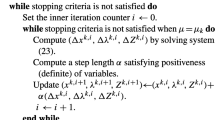

This paper illustrates the application of a two-level approximation method for truss topology optimization with local member buckling constraints and restrictions on member intersections and overlaps. Previously developed for truss topology optimization with stress and displacement constraints, that method is achieved by starting from an initial ground structure, and, combined with genetic algorithm (GA), it can handle both discrete and continuous variables, which denote the existence and cross-sectional areas of bar members respectively in the ground structure. In this work, this method is improved and extended to consider member buckling constraints and restrict intersection and overlap of members for truss topology optimization. The temporary deletion technique is adopted to temporarily remove buckling constraints when related bar members are deleted, and in order to avoid unstable designs, the validity check for truss topology configuration is conducted. By using GA to search in each possible design subset, the singularity encountered in buckling-constrained problems is remedied, and meanwhile, as the required structural analysis is replaced with explicit approximation functions in the process of executing GA, the computational cost is significantly saved. Moreover, for the consideration of restrictions on member intersecting and overlapping, the definition of such phenomena and mathematical expressions to recognize them are presented, and a new fitness function is developed to include such considerations. Numerical examples are presented to show the efficacy of the proposed techniques.

Similar content being viewed by others

References

Achtziger W (1999a) Local stability of trusses in the context of topology optimization part I: exact modelling. Struct Optim 17(4):235–246

Achtziger W (1999b) Local stability of trusses in the context of topology optimization part II: a numerical approach. Struct Multidiscip Optim 17(4):247–258

Achtziger W (2000) Optimization with variable sets of constraints and an application to truss design. Comput Optim Appl 15(1):69–96

An H, Chen S, Huang H (2015) Simultaneous optimization of stacking sequences and sizing with two-level approximations and a genetic algorithm. Compos Struct 123:180–189

An H, Huang H (2017) Topology and Sizing Optimization for Frame Structures with a Two-Level Approximation Method. AIAA J 55(3):1044–1057

An H, Xian K, Huang H (2016) Actuator placement optimization for adaptive trusses using a two-level multipoint approximation method. Struct Multidiscip Optim 53(1):29–48

Chen S, Lin Z, An H, Huang H, Kong C (2013) Stacking sequence optimization with genetic algorithm using a two-level approximation. Struct Multidiscip Optim 48(4):795–805

Chen S, Shui X, Huang H (2017) Improved genetic algorithm with two-level approximation using shape sensitivities for truss layout optimization. Struct Multidiscip Optim 55(4):1365–1382

Chen S, Shui X, Li D, Huang H (2015) Improved genetic algorithm with two-level approximation for truss optimization by using discrete shape variables. Math Probl Eng 2015(6):1–11

Cheng G (1995) Some aspects of truss topology optimization. Struct Multidiscip Optim 10(3):173–179

Cheng G, Guo X (1997) ε-relaxed approach in structural topology optimization. Struct Multidiscip Optim 13(4):258–266

Cheng G, Guo X, Olhoff N (2000) New formulation for truss topology optimization problems under buckling constraints. Topology Optimization of Structures and Composite Continua. Kluwer Academic Publishers, In, pp 115–131

Cheng G, Jiang Z (1992) Study on topology optimization with stress constraints. Eng Optim 20(2):129–148

Dong Y, Huang H (2004) Truss topology optimization by using multi-point approximation and GA. Chinese J Comput Mech 21(6):746–751

Dorn WS (1964) Automatic design of optimal structures. Journal de Mecanique 3:25–52

Guo X, Cheng G, Olhoff N (2005) Optimum design of truss topology under buckling constraints. Struct Multidiscip Optim 30(3):169–180

Guo X, Cheng G, Yamazaki K (2001) A new approach for the solution of singular optima in truss topology optimization with stress and local buckling constraints. Struct Multidiscip Optim 22(5):364–373

Hajela P, Lee E (1995) Genetic algorithms in truss topological optimization. Int J Solids Struct 32(22):3341–3357

Kawamura H, Ohmori H, Kito N (2002) Truss topology optimization by a modified genetic algorithm. Struct Multidiscip Optim 23(6):467–473

Leng G, Qiu Y, Bao H (2012) Topology optimization of frame strcture based on intersection-filter. Engineering Mechanics 2:013

Leng G, Zhang Z, Bao H, Yang D (2013) Topology optimization of truss structrue based on overlapping-filter and stability constraints. Engineering Mechanics 2:001

Li D, Chen S, Huang H (2014) Improved genetic algorithm with two-level approximation for truss topology optimization. Struct Multidiscip Optim 49(5):795–814

Li J (2015) Truss topology optimization using an improved species-conserving genetic algorithm. Eng Optim 47(1):107–128

Li L, Khandelwal K (2017) Topology optimization of geometrically nonlinear trusses with spurious eigenmodes control. Eng Struct 131:324–344

Liu X, Cheng G, Yan J, Jiang L (2012) Singular optimum topology of skeletal structures with frequency constraints by AGGA. Struct Multidiscip Optim 45(3):451–466

Mela K (2014) Resolving issues with member buckling in truss topology optimization using a mixed variable approach. Struct Multidiscip Optim 50(6):1037–1049

Nocedal J, Wright SJ (2006) Sequential quadratic programming. Springer

Ohsaki M (1995) Genetic algorithm for topology optimization of trusses. Comput Struct 57(2):219–225

Ohsaki M, Katoh N (2005) Topology optimization of trusses with stress and local constraints on nodal stability and member intersection. Struct Multidiscip Optim 29(3):190–197

Richardson JN, Adriaenssens S, Bouillard P, Coelho RF (2012) Multiobjective topology optimization of truss structures with kinematic stability repair. Struct Multidiscip Optim 46(4):513–532

Rozvany GI (1996) Difficulties in truss topology optimization with stress, local buckling and system stability constraints. Struct Multidiscip Optim 11(3):213–217

Sawada K, Matsuo A, Shimizu H (2011) Randomized line search techniques in combined GA for discrete sizing optimization of truss structures. Struct Multidiscip Optim 44(3):337–350

Stolpe M, Svanberg K (2003) A note on stress-constrained truss topology optimization. Struct Multidiscip Optim 25(1):62–64

Sved G, Ginos Z (1968) Structural optimization under multiple loading. Int J Mech Sci 10(10):803–805

Tang W, Tong L, Gu Y (2005) Improved genetic algorithm for design optimization of truss structures with sizing, shape and topology variables. Int J Numer Methods Eng 62(13):1737–1762

Xian K, Huang H (2008) Research on algorithm of optimal actuator/sensor location for piezoelectric truss. Chin J Comput Mech 25(6):827–832

Xu B, Ou J, Jiang J (2013) Integrated optimization of structural topology and control for piezoelectric smart plate based on genetic algorithm. Finite Elem Anal Des 64:1–12

Zhou M (1996) Difficulties in truss topology optimization with stress and local buckling constraints. Struct Multidiscip Optim 11(1):134–136

Acknowledgments

This research work is supported by the National Natural Science Foundation of China (Grant No. 11672016), which the authors gratefully acknowledge.

Author information

Authors and Affiliations

Corresponding author

Appendices

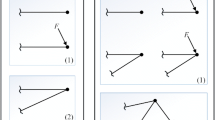

Appendix 1: Definition of member intersecting and overlapping

In this work, the intersection of two bars is defined as: the two bars are non-collinear and their intersectional point is inside their lengths. The schematic diagrams for the two types of intersection are shown in Fig. 17 where l1 and l2 represents any two bars in the truss. As for the overlap, it is defined as: the two bars are collinear, and a hinge node of one bar is located inside the length of the other bar. Likewise, the schematic diagrams for the three types of overlap are shown in Fig. 18.

For the bar nodes in Figs. 17 and 18, the hollow dots represent the normal hinge nodes, while the solid dots represent the bar nodes located inside the length of the other bar, which should be regarded as intersectional or overlapped points.

It is obvious that the intersection and overlap types defined above can include all the conditions where any two bars generate intersectional or overlapped points without physical meaning.

Appendix 2: Mathematical recognition of intersections and overlaps

Information of location coordinates for all nodes can be obtained from the structural model, and, based on the node coordinates, as shown in Fig. 19, the vectors (\( \overrightarrow{a} \), \( \overrightarrow{b} \), \( {\overrightarrow{s}}_1 \), \( {\overrightarrow{s}}_2\kern0.1em \)) can be constructed and used to exactly determine whether any two bars of the structure are intersecting or overlapping. Here, lA and lB represent any two bars with node points A1A2 and B1B2 respectively. \( \overrightarrow{a} \) is a vector defined for lA from point A1 to point A2, and similarly, \( \overrightarrow{b} \) is a vector defined for lB. \( {\overrightarrow{s}}_1 \) and \( {\overrightarrow{s}}_2 \) are two vectors defined from A1 to B1/B2,respectively.

Corresponding to the intersection or overlap types defined in Appendix 1, the strategy to recognize them is presented as follows:

-

1)

For intersection Type-1, such relationship between two bars can be determined by the following three conditions.

-

a.

\( \overrightarrow{a}\nparallel \overrightarrow{b} \), and the two bars are not hinge-jointed.

-

b.

Both hinge nodes of either bar are located beyond the length of the other bar.

-

c.

Values of the real number λ1 and λ2 exist to satisfy (24) and (25).

Here, (24) is a group of linear algebraic equations with respect to λ1 and λ2. Disassembling the vectors into their components in 3D space, these linear algebraic equations can be expressed as the (26). We can see that (26) consist of three linear algebraic equations with only two unknown variables. After solving it, one of the two conditions will appear: If (26) has no solution, the two bars are located in the different planes of the space, so they are not intersecting; if the real solutions λ1 and λ2 exist, i.e., two of the three equations in (26) are linear dependent, the two bars are coplanar, and when (25) is also satisfied, the two bars are intersecting with each other.

-

2)

The intersection Type-2 corresponds to the following two conditions.

-

a.

\( \overrightarrow{a}\nparallel \overrightarrow{b} \), and the two bars are not hinge-jointed.

-

b.

One hinge node of one bar is located inside the length of the other bar.

-

3)

Corresponding to the overlap Type-1 -2 and −3, such relationships can be determined by satisfying the following two conditions.

-

a.

\( \overrightarrow{a}\parallel \overrightarrow{b} \).

-

b.

One hinge node of one bar is located inside the length of the other bar.

Among the determining conditions above, the parallel relationship between the two vector \( \overrightarrow{a} \) and \( \overrightarrow{b} \) can be determined if (27) is satisfied, and, for example, point P is located inside the length of the bar lA if (28) is satisfied, where the definition of \( {\overrightarrow{p}}_1 \), \( {\overrightarrow{p}}_2 \) and \( \overrightarrow{a} \) can be clearly seen in Fig. 20.

It should be noted that, the recognition method for intersections and overlaps in this work is expressed in 3D space, and it can also be used easily in 2D truss structures only by fixing the value of one coordinate component to be a constant value, such as zero.

Rights and permissions

About this article

Cite this article

Cui, H., An, H. & Huang, H. Truss topology optimization considering local buckling constraints and restrictions on intersection and overlap of bar members. Struct Multidisc Optim 58, 575–594 (2018). https://doi.org/10.1007/s00158-018-1910-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00158-018-1910-x