Abstract

The experimental basis for testing the biological durability of wood often includes incubation experiments with wood-destroying basidiomycetes. Numerous parameters can affect the mass loss by fungal decay (MLF) in laboratory durability tests and therefore being decisive for the resulting durability classification. Among others, the dimension of the wood specimen and the time of incubation impact on fungal decay. Hence, both parameters were examined within this study using 19 different specimen formats and four different incubation times. Specimens of larch heartwood (Larix decidua Mill.) were incubated with pure cultures of the brown rot fungus Coniophora puteana. Scots pine sapwood (Pinus sylvestris L.) was used as a reference. The wood specimens’ format turned out to significantly affect both mass loss by fungal decay (MLF) and resulting x-values when MLF of larch was compared with that of the reference Scots pine sapwood. Both measures were highest for specimen formats with moderate surface-volume ratios. MLF and x-values depended on specimen size and shape as well as on the time of incubation. Reducing the specimen volume generally led to higher MLF at a given incubation time, but prolonging incubation times led to higher x-values and thus to lower durability expressed as durability classes (DC). In summary, it appeared highly questionable that results of basidiomycete durability tests can be easily compared to each other when specimen format and/or incubation time deviate from the standard conditions.

Similar content being viewed by others

1 Introduction

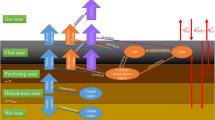

The biological durability of wood varies against different decay organisms as well as within and between wood species (Scheffer and Morrell 1998; Brischke et al. 2013). Some tropical timbers, which are rich in extractives, are among the most durable wood species; sapwood and non-coloured heartwoods are often less or non-durable (e.g. Scheffer and Morrell 1998; Taylor et al. 2002). Wood is generally prone to degradation by many organisms including wood-boring beetles, ants and termites, wood-destroying fungi, bacteria, and different marine borers. Outside the marine environment and in regions where termites are not present, decay fungi are the most critical biological hazard for wood used outdoors or elsewhere under humid conditions (e.g. Jones and Brischke 2017). The durability of wood against wood-destroying fungi can be determined using many different test protocols, which all have in common that the test result is a relative value. Under laboratory conditions, wood can be incubated with different decay fungi in agar plate tests, in soil block tests or in soil bed tests (so-called terrestrial microcosms containing unsterile natural top soil, CEN/TS 15083-1 2005; CEN/TS 15083-2 2005; EN 113 1996; AWPA E10 2015; prEN 113-2 2018). Fungal (and bacterial) degradation can be assessed and quantified by determination of mass loss or loss in elasto-mechanical properties (Wilcox 1978). Since the severity of fungal decay depends on the virulence of the test fungus and the test conditions, the test results can vary and need to be set into perspective. Therefore, reference species are tested and compared with the tested material. Most reference species are per definition ‘non-durable’, such as the sapwood of Scots pine (Pinus sylvestris), Radiata pine (Pinus radiata), Southern pine (Pinus spp.), or European beech (Fagus sylvatica). The obtained relative values (‘x-values’) are assigned to durability classes, for example five classes between ‘very durable’ (DC 1) and ‘non-durable’ (DC 5) according to EN 350 (2016) as shown exemplarily in Table 1.

As an alternative to laboratory tests, wood durability can be determined in field tests where wood specimens are exposed in ground (e.g. AWPA E7 2013; EN 252 2015) or above ground (e.g. CEN/TS 12037 2003, AWPA E18 2013; EN 330 2015). Field tests are considered more realistic compared to laboratory tests but require longer test durations; which are often inacceptable for clients and producers of wood-based products. Furthermore, field tests also require reference materials and a field test does not provide durability data in an absolute manner since the characteristics of the individual locations (e.g. climate, soil characteristics, fungal inoculum potential) affect performance and resulting service lives.

In contrast, several possibilities have been reported to accelerate both, field and laboratory durability tests. Decay rates in field tests can be increased by using pre-infected feeder-stakes, using water-trapping test configurations, providing extra moisture through spraying and dripping systems, and by applying elevated temperatures, either in green houses or by using warm and humid test locations (Meyer et al. 2016). Alternatively, the use of smaller test specimens can lead to shorter exposure periods until failure occurs as previously reported from so-called graveyard tests by different authors (Westin et al. 2002; Antwi-Boasiako and Allotey 2010; Brischke and Meyer-Veltrup 2017). In analogy, specimens for laboratory decay tests have been reduced in size with the aim of shortening the incubation time needed to achieve a requested mass loss, for example of a reference material. Worldwide, the most often used miniaturized specimen format is 5 × 10 × 30 (long.) mm³, the so-called ‘mini-blocks’ and sometimes ‘Braveries’ named after Dr. Anthony Bravery, who suggested the format (Bravery 1978). A mini-block has only 60% of the length, and 28% of the volume of a standard specimen, i.e. 15 × 25 × 50 mm³ according to CEN/TS 15083-1 (2005) and prEN 113-2 (2018). Bravery (1978) also pointed out that besides the mass of the specimen its surface to volume ratio and the proportion of end grain influence the decay rate. Finally, he gave preference to the mini-blocks, because they suffered from rapid decay, fit well into Petri dishes, and were already considered for inclusion in a European standard. Furthermore, toxic values of different wood preservatives obtained after an incubation period of 6 weeks compared well with those obtained after 12 weeks using the British standard specimens of 15 × 25 × 50 (long.) mm³. Nevertheless, later, mini-block tests were frequently performed using deviating incubation periods of 8 weeks (Palanti et al. 2012; Temiz et al. 2014) and 12 weeks (Ghosh et al. 2008; Verma et al. 2008). Several authors (e.g. Pohleven et al. 2000; Deklerck et al. 2017) pointed to the effect of incubation time and suggested incubation periods longer than 6 weeks to achieve more similar mass loss data compared with standard specimens and the standard incubation period, which is 16 weeks according to CEN/TS 15083-1 (2005) and prEN 113-2 (2018).

Further, different specimen shapes and dimensions have been used. Among others, the following have been reported: 10 × 10 × 3 (long.) mm³ (Brown et al. 1991), 10 × 30 × 10 (long.) mm³, 30 × 30 × 5 (long.) mm³ (Brischke et al. 2012), 15 × 5 × 40 mm³ (Lenz et al. 2017), 40 × 40 × 1–2 mm³ (Sutter 1987), and cylindrical specimens (d = 10 mm; length 30 mm) (Brischke et al. 2012). The reasons for using differently sized test specimens can be manifold, such as limited dimensions and volume of the test material (e.g. when products are tested), durability gradients within the test material (e.g. in impregnated wood), and finally to reduce the incubation time. Systematic comparative studies on the effect of specimen shape and dimension are rare. Brischke et al. (2012) compared mass loss after 12 weeks of incubation and found no differences in relative mass losses of English oak (Quercus robur) between drilling cores, discs and cubes compared to European beech serving as reference. In contrast, others such as Pohleven et al. (2000) and Larnøy et al. (2014) pointed to the effect of specimen size besides numerous further factors that can affect the results of laboratory decay tests in terms of mass loss. Reproducibility is a key requirement for laboratory test methods, but to the best knowledge of the authors a systematic and comprehensive study on the effect of specimen shape and dimension is still lacking. Therefore, this study aimed at comparing mass loss of Scots pine sapwood and European larch heartwood (Larix decidua) specimens in 19 different formats and after different periods of incubation with the brown rot fungus Coniophora puteana. The objectives of the study were to quantify the effect of specimen format on the mass loss in durability experiments and how the latter may affect durability classification based on mass loss data.

2 Materials and methods

2.1 Wood specimens

Specimens of different shapes and dimensions were prepared from single stems of Scots pine sapwood (Pinus sylvestris L.) and European larch heartwood (Larix decidua Mill.) to reduce the effect of intra-species variation in material resistance. In total, 1520 specimens were made in 19 different dimensions (Table 2) and n = 10 replicate specimens were used for each combination of format and incubation time.

The specimen dimensions were carefully selected to fulfil the following criteria:

-

Doubled end-grain areas (here: 1, 2, 4, 8, and 16 cm2).

-

Doubled length of the specimens within one group with equal end grain area (here: 10, 20, 40, and 80 mm).

-

Cubic specimens for each width or thickness respectively.

-

Specimens need to fit into a Kolle flask or polyethylene screw jars (here: maximum length 80 mm, maximum thickness 28.3 mm).

Specimens representing standard specimens according to CEN/TS 15083-1 (2005) and mini-block specimens according to Bravery (1978) were also prepared.

All specimens were pre-aged according to EN 84 (1997). All specimens were oven-dried at 103 ± 2 °C for 48 h, weighed to the nearest 0.001 g, and afterwards submerged in deionized water in plastic containers. After a vacuum impregnation at 4 kPa during 20 min, the specimens were kept submerged and the water was exchanged ten times during 14 days according to EN 84 (1997). After the leaching procedure, the specimens were carefully dried in four steps each of 24 h (20, 40, 70, and 103 °C).

2.2 Durability test with a Coniophora puteana monoculture

Laboratory decay resistance tests were conducted according to a modified CEN/TS 15083-1 (2005) protocol as follows: All specimens were oven-dried at 103 ± 2 °C for 48 h, weighed to the nearest 0.001 g, and afterwards conditioned at 20 °C/65% RH until constant mass. After sterilization in an autoclave at 121 °C and 2.4 bar for 20 min, two specimens of the same species and dimensions were placed on fungal mycelium in a Kolle flask. Ten replicates per specimen format were tested. To avoid direct contact between wood and overgrown malt agar (4%) stainless steel washers were placed in between. The incubation times were 4, 8, 12, and 16 weeks. The following test fungus was used: Coniophora puteana = (Schum.:Fr.) P. Karsten BAM Ebw. 15. After incubation, the specimens were cleaned from adhering mycelium, oven-dried, weighed to the nearest 0.001 g, and mass loss (MLF) was calculated according to Eq. 1.

Equation 1: Calculation of mass loss by fungal decay MLF:

m0,i is the oven-dry mass before incubation after leaching, m0,F is the oven-dry mass after incubation.

2.3 Durability classification and statistical analysis

The durability of European larch heartwood was classified according to EN 350 (2016) based on x-values (Table 1) for the different specimen dimensions and incubation periods. In addition, durability was classified based on median MLF according to CEN/TS 15083-1 (2005) after the standard incubation time of 16 weeks.

The arithmetic mean and the median were calculated for MLF and wood MC. The standard deviation (SD) was used to calculate the coefficients of variation (COV) as a percentage of the corresponding mean value. Regression curves were established using the method of least squares based on 2nd polynomial or potential fitting functions, respectively, to evaluate the interrelationship between selected parameters such as MLF, COV (MLF), specimen volume, specimen surface-volume ratio, and the x-values obtained. The quality of fitting has been assessed based on the degree of determination R2.

3 Results and discussion

3.1 Mass loss by fungal decay (MLF)

The average mass loss (MLF) caused by C. puteana differed between the two tested wood species, increased with incubation time and varied between the different specimen dimensions in both absolute and relative amounts as shown in Figs. 1 and 2. As expected, absolute MLF in grams differed more between specimen configurations than percentage MLF, but only the latter was used to analyze the effect of specimen size and shape on wood metabolizing through the fungus at a given incubation time.

The less durable Scots pine sapwood (durability class 5, DC 5, EN 350 2016) was more decayed than larch heartwood (DC 3–4, EN 350 2016). However, after 16 weeks of incubation, the mean MLF of larch exceeded 40% in specimen configurations 9 and 10, but was below 5% in the smallest specimens, i.e. configuration 1. Consequently, the overall range in MLF was clearly higher in larch compared to Scots pine sapwood. Mean MLF of Scots pine sapwood varied between 20 and 50% after 16 weeks of incubation (Fig. 1).

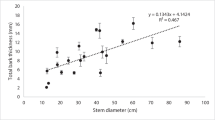

The smallest specimens in terms of volume and thus of mass (e.g. configurations 1–4 and 19) showed the lowest absolute and often also the lowest relative MLF. This contradicts to some extent that the incubation intervals usually applied in experiments with small specimens such as mini-blocks are reduced (Bravery 1978; Verma et al. 2005; Palanti et al. 2012; Larnøy et al. 2014; Temiz et al. 2014) compared to standard conditions (e.g. EN 113 1996; CEN/TS 15083-1 2005). Hence, it had been hypothesized that mass loss is increasing with longer incubation times. However, as can be seen from Fig. 2, some of the medium-volume configurations showed the highest relative MLF, but not those with highest or lowest volume. Therefore, further parameters than specimen volume were correlated with MLF for both wood species. In Table 3, the degrees of determination R² are summarized based on 2nd polynomial fitting functions. The best fit was found between the surface-volume ratio and MLF when looking at all four incubation intervals, which is separately shown in Fig. 3. However, from the R² values shown in Table 3, it can also be seen that the fit between the various parameters and MLF depended on the incubation time and the wood species.

In addition to the differences in average absolute and percentage MLF, the latter varied with specimen volume and incubation time as shown in Fig. 4. The more voluminous the specimens the smaller was the coefficient of variation of the percentage mass loss (COV (MLF)). In addition, the COV (MLF) was higher after shorter incubation intervals which became more prominent with larch heartwood compared to Scots pine sapwood. The MLF of larch heartwood varied generally stronger than that of Scots pine sapwood, which confirms previous findings by Brischke et al. (2018), who compared the MLF of sapwood and heartwood of Scots pine and Douglas fir (Pseudotsuga menziesii) and English oak (Quercus robur) and showed that the more durable heartwood usually has higher variation in MLF than corresponding sapwood.

3.2 Durability classes

In durability testing, reference species, such as Scots pine sapwood, are frequently used to become independent from the actual virulence of the test fungi and the applied incubation time. Therefore, x-values can be calculated and assigned to DC as previously summarized in Table 1. The x-values of larch are shown in Fig. 5 and correlated with the surface-volume ratio of the different specimen groups. The general trend that specimens with medium surface-volume ratios show highest MLF also became evident for the x-values.

Notably, durability expressed as DC was decreasing with increasing incubation time (Table 4). The mean x-value of larch increased from 0.23 (DC 3) after four weeks to 0.57 (DC 4) after 16 weeks of incubation. All this might be explained by the fact that Scots pine sapwood is approaching a maximum MLF with increasing incubation time. Interestingly, neither the standard specimens (Surface/Volume = S/V = 2.53) according to CEN/TS 15083-1 (2005) nor the mini-block specimens (S/V = 6.67) according to Bravery (1978) were among those expected to provide high MLF and x-values, respectively.

For 4 out of 19 groups the DC improved from 12 to 16 weeks of incubation, i.e. for the groups 1, 3, 4, and 19, which also showed the smallest specimen volumes. Furthermore, these four groups revealed some of the highest DC when using the median MLF and the assignment scheme according to CEN/TS 15083-1 (2005), i.e. DC 1 and DC 2 respectively (Table 4). Apparently, MLF of larch specimens did not develop as well as one would expect from those determined in Scots pine specimens after the same incubation period (see Figs. 1 and 2). However, no clear relationship between specimen volume and the improvement of DC became evident from the recent data.

In previous studies, MLF of mini-block specimens after 8 weeks of incubation were frequently used instead of those obtained with standard specimens (CEN/TS 15083-1 2005) after 16 weeks of incubation (e.g. Palanti et al. 2012; Pilgård et al. 2013; Larnøy et al. 2014; Temiz et al. 2014). Based on recent findings from this study it might be questioned whether the accelerated testing using mini-blocks or other deviating specimen formats leads to the same or even similar durability classes.

4 Conclusion

The wood specimens’ format turned out to significantly affect both mass loss by fungal decay MLF and resulting x-values when MLF of larch is compared with that of the reference Scots pine sapwood. Both measures were highest for specimen formats with moderate surface-volume ratios. The following can be concluded from the decay tests within this study:

-

MLF and x-values depend on specimen size and shape as well as on the time of incubation.

-

Reducing the specimen volume does not inevitably lead to higher MLF in decay tests at a given incubation time.

-

Prolonging incubation times (at least within the span between 4 and 16 weeks) generally leads to higher x-values and thus to lower durability expressed as DCs.

-

The x-values obtained using mini-blocks (independent from the incubation time) were never close to those obtained with standard specimens according to CEN/TS 15083-1 (2005), i.e. resulting classification differed between DC 2 and DC 3 with mini-blocks and DC 5 using standard specimens.

-

Generally, DCs based on x-values obtained with smaller test specimens such as the ‘mini-blocks’ appeared to be more stable during incubation compared to larger specimens, although variation in mass loss MLF decreased with increasing specimen volume.

In summary, it appeared highly questionable that results of basidiomycete durability tests can be easily compared to each other when specimen format and/or incubation time deviate from the standard conditions. However, one should note that this study included only one test fungus and one test timber. Hence, validation through tests with additional materials and test fungi representing different decay types and physiological requirements is needed.

Change history

29 June 2021

A Correction to this paper has been published: https://doi.org/10.1007/s00107-021-01730-1

References

Antwi-Boasiako C, Allotey A (2010) The effect of stake dimension on the field performance of two hardwoods with different durability classes. Int Biodeter Biodegrad 64:267–273

AWPA E7 (2013) Standard field test for evaluation of wood preservatives to be Used in Ground Contact (UC4A, UC4B, UC4C): stake test. American Wood Protection Association, Birmingham

AWPA E10 (2015) Standard method of testing wood preservatives by laboratory soil-block cultures. American Wood Protection Association, Birmingham

AWPA E18 (2013) Standard field test for evaluation of wood preservatives to be Used Above Ground (UC3B): ground proximity decay test. American Wood Protection Association, Birmingham

Bravery AF (1978) A miniaturised wood-block test for the rapid evaluation of wood preservative fungicides. In: The International Research Group on Wood Preservation, IRG/WP/78-2113, 10th Annual Meeting, Peebles, Scotland

Brischke C, Behnen CJ, Lenz MT, Brandt K, Melcher E (2012) Durability of oak timber bridges–Impact of inherent wood resistance and environmental conditions. Int Biodeter Biodegrad 75:115–123

Brischke C, Gellerich A, Homann P (2018) Impact of sapwood portions on the durability of adjacent heartwood of Pinus sylvestris, Pseudotsuga menziesii and Quercus robur. Part 1: laboratory studies. The International Research Group on Wood Protection, IRG/WP/18-10922, 48th Annual Meeting, Johannesburg, South Africa

Brischke C, Meyer L, Alfredsen G, Humar M, Francis L, Flæte PO, Larsson-Brelid P (2013) Natural durability of timber exposed above ground-a survey. Drvna Ind 64:113–129

Brischke C, Meyer-Veltrup L (2017) Durability of wood in ground contact–effects of specimen size. Pro Ligno 13:3–9

Brown J, Caswell S, Williams GR (1991) Development of a mini-block test method for the rapid evaluation of preservative performance against Basidiomycte fungi. International Research Group on Wood Protection, Stockholm, pp 91–2379

CEN/TS 12037 (2003) Wood preservatives-field test method for determining the relative protective effectiveness of a wood preservative exposed out of ground contact-Horizontal lap-joint method. European Committee for Standardization, Brussels

CEN/TS 15083-1 (2005) Durability of wood and wood-based products-Determination of the natural durability of solid wood against wood-destroying fungi, test methods -Part 1: Basidiomycetes. European Committee for Standardization, Brussels

CEN/TS 15083-2 (2005) Durability of wood and wood-based products-Determination of the natural durability of solid wood against wood-destroying fungi, test methods-Part 2: soft rotting micro-fungi. European Committee for Standardization, Brussels

Deklerck V, De Windt I, Defoirdt N, Van den Bulcke J, Beeckman H, Espinoza E, Van Acker J (2017) Assessing the natural durability for different tropical timber species using the mini-block test. In: The International Research Group on Wood Protection, IRG/WP/17-10886, 48th Annual Meeting, Ghent, Belgium

EN 84 (1997) Wood preservatives-Accelerated ageing of treated wood prior to biological testing-Leaching procedure. European Committee for Standardization, Brussels

EN 113 (1996) Wood preservatives-Method of test for determining the protective effectiveness against wood destroying basidiomycetes-Determination of the toxic values. European Committee for Standardization, Brussels

EN 252 (2015) Field test method for determining the relative protective effectiveness of a wood preservative in ground contact. European Committee for Standardization, Brussels

EN 330 (2015) Wood preservatives-Determination of the relative protective effectiveness of a wood preservative for use under a coating and exposed out-of-ground contact-Field test: L-joint method. European Committee for Standardization, Brussels

EN 350 (2016) Durability of wood and wood-based products-Testing and classification of the durability to biological agents of wood and wood-based materials. European Committee for Standardization, Brussels

Ghosh SC, Militz H, Mai C (2008) Decay resistance of treated wood with functionalised commercial silicones. BioResources 3:1303–1314

Jones D, Brischke C (eds) (2017) Performance of bio-based building materials. Elsevier, Woodhead Publishing, Amsterdam

Lenz C, Melcher E, Möller R, Lautner S (2017) Microscopic investigations concerning in situ oxalate formation by the brown-rot fungus Poria placenta. Drewno Prace Naukowe Doniesienia Komunikaty 60:5–19

Larnøy E, Alfredsen G, Treu A, Kolstad S (2014) A screening of factors that might influence the result of laboratory decay tests. In: The International Research Group on Wood Protection, IRG/WP/14-20548, 45th Annual Meeting, St. George, USA

Meyer L, Brischke C, Preston A (2016) Testing the durability of timber above ground: a review on methodology. Wood Mat Sci Eng 11:283–304

Palanti S, Feci E, Predieri G, Vignali F (2012) Copper complexes grafted to amino-functionalized silica gel as wood preservatives against fungal decay: mini-blocks and standard test. BioResources 7:5611–5621

Pilgård A, Brischke C, Meyer L (2013) Relevance of natural pre-weathering for laboratory decay tests with native, modified, and preservative-treated wood. In: The International Research Group on Wood Protection, IRG/WP/13-20522, 44th Annual Meeting, Stockholm, Sweden

Pohleven F, Petric M, Zupin J (2000) Effect of mini-block test conditions on activity of Coniophora puteana. In: The International Research Group on Wood Protection, IRG/WP/00-20184, 31st Annual Meeting, Kona, Hawaii, USA

prEN 113-2 (2018) Durability of wood and wood-based products-test method against wood destroying basidiomycetes-part 2: Assessment of inherent or enhanced durability. European Committee for Standardization, Brussels

Scheffer TC, Morrell JJ (1998) Natural durability of wood: a worldwide checklist of species. Forest Research Laboratory, Oregon State University. Res Contrib 22:58

Sutter HP (1987) A new technique for screening fungicides for wood preservatives. Int Biodeter Bull 23:95–99

Taylor AM, Gartner BL, Morrell JJ (2002) Heartwood formation and natural durability-a review. Wood Fiber Sci 34:587–611

Temiz A, Alfredsen G, Yildiz UC, Gezer ED, Kose G, Akbas S, Yildiz S (2014) Leaching and decay resistance of alder and pine wood treated with copper based wood preservatives. Maderas Cienc Tecnol 16:63–76

Verma P, Mai C, Krause A, Militz H (2005) Studies on the resistance of DMDHEU treated wood against white-rot and brown-rot fungi. In: The International Research Group on Wood Protection, IRG/WP/05-10566, 36th Annual Meeting, Bangalore, India

Verma P, Dyckmans J, Militz H, Mai C (2008) Determination of fungal activity in modified wood by means of micro-calorimetry and determination of total esterase activity. Appl Microbiol Biotechnol 80:125–133

Westin M, Rapp AO, Hadi YS, Nilsson T (2002) Field trials with mini-stakes. In: The International Research Group on Wood Protection, IRG/WP/02-20244, 33rd Annual Meeting, Cardiff, Wales

Wilcox WW (1978) Review of literature on the effects of early stages of decay on wood strength. Wood Fiber Sci 9:252–257

Acknowledgements

Dr. Gry Alfredsen is deeply acknowledged for her valuable comments on the manuscript and for sharing her knowledge and her experience with mini-block tests.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations'.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Brischke, C., Grünwald, L.K. & Bollmus, S. Effect of size and shape of specimens on the mass loss caused by Coniophora puteana in wood durability tests. Eur. J. Wood Prod. 78, 811–819 (2020). https://doi.org/10.1007/s00107-020-01559-0

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-020-01559-0