Abstract

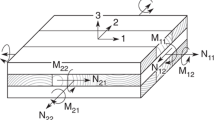

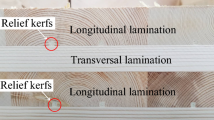

Cross Laminated Timber (CLT) is made by laminating three or more timber layers with grain directions in alternate layers at right angles to each other. This structure, with its numerous wood bonds glued in cross-grained directions, develops residual stresses whenever panels are exposed to variations in temperature or moisture content. This paper analyzes how these residual stresses combined with mechanical stresses can cause CLT cracks by deriving an expression for energy released when a new crack forms within one layer. By using finite fracture mechanics concepts, where a crack forms when energy released by that crack exceeds the transverse toughness of wood, this equation can predict layer cracking under many conditions. Two specific examples given are cracking due to residual shrinkage alone and cracking due to uniaxial tension. Finite fracture mechanics and energy release calculations provide useful tools for designing durable CLT products and structures. Various options for improving CLT are considered along with needs for more analysis and experiments. Two simple changes to CLT that could greatly enhance durability are to use thinner layers and to sufficiently dry the timber before panel fabrication.

Similar content being viewed by others

References

Batey TEJ (1955) Minimizing face checking of plywood. For Prod J 5(10):277–284

Bogensperger T, Moosbrugger T, Silly G (2010) Verification of clt-plates under loads in plane. In: World conference on timber engineering, June. Riva del Garda, Italy, pp 20–24

Cheng W, Finnie I (2007) Residual Stress Measurement and the Slitting Method. Springer, Boston

Christenson RM (1979) Mechanics of composite materials. Wiley, New York

Crossman FW, Wang ASD (1982) The dependence of transverse cracking and delamination on ply thickness in graphite/epoxy laminates. ASTM STP 775:118–139

Crossman FW, Warren WJ, Wang ASD, Law GE Jr (1980) Initiation and growth of transverse cracks and edge delamination in composite laminates: Part 2. experimental correlation. J Comp Mat Suppl 14:89–108

Forest Products Laboratory (2010) Wood handbook: wood as an engineering material. General technical report FPL-GTR-190. Madison, WI: U.S. Dept. of Agriculture, Forest Service, Forest Products Laboratory

Fruhmann K, Reiterer A, Tschegg EK, Stanzl-Tschegg SS (2002) Fracture characteristics of wood under mode i, mode ii and mode iii loading. Philos Mag A Phys Condens Matter Struct Defects Mech Prop 82(17–18):3289–3298

Gent AN (1990) Cavitation in rubber: a cautionary tale. Rubber Chem Technol 63(3):49–53

Gent AN, Lindley PB (1959) Internal rupture on bonded rubber cylinders in tension. Proc R Soc Lond A 249:195–205

Gent AN, Wang C (1991) Fracture mechanics and cavitation in rubber-like solids. J Mat Sci 26(12):3392–3395

Gilchrist MD, Kinloch AJ, Mathews F, Osiyemi SO (1996) Mechanical performance of carbon- fibre- and glass-fibre-reinforced epoxy I-beams: I Mechanical. Compos Sci Tech 56:37–53

Groisman A, Kaplan E (1994) An experimental study of cracking induced by desiccation. Europhys Lett 25(6):415

Hashin Z (1987) Analysis of orthogonally cracked laminates under tension. J Appl Mech 54:872–879

Hashin Z (1996) Finite thermoelastic fracture criterion with application to laminate cracking analysis. J Mech Phys Solids 44:1129–1145

Hu S, Bark JS, Nairn JA (1993) On the phenomenon of curved microcracks in \([({S})/90_n]_s\) laminates: their shapes, initiation angles, and locations. Compos Sci Tech 47:321–329

Johnson JA (1973) Crack initiation in wood plates. Wood Sci 6(2):151–158

Kim SR, Nairn JA (2000a) Fracture mechanics analysis of coating/substrate systems subjected to tension or bending loads I: theory. Engr Fract Mech 65:573–593

Kim SR, Nairn JA (2000b) Fracture mechanics analysis of coating/substrate systems subjected to tension or bending loads II: experiments in bending. Eng Fract Mech 65:595–607

Leterrier Y, Andersons J, Pitton Y, Månson JAE (1997a) Adhesion of silicon oxide layers on poly(ehtylene terepthalate). II Effect of coating thickness on adhesive and cohesive strengths. J Polym Sci Part B Polym Phys 35:1463–1472

Leterrier Y, Boogh L, Andersons J, Månson JAE (1997b) Adhesion of silicon oxide layers on poly(ehtylene terepthalate). I: effect of substrate properties on coating’s fragmentation process. J Polym Sci Part B Polym Phys 35:1449–1461

Leterrier Y, Fischer C, Médico L, Demarco F, Månson JAE, Bouten P, DeGoede J, Nairn JA (2003) Mechanical properties of transparent functional thin films for flexible displays. In: Proceedings of 46th annual technical conference society of vacuum coaters

Leterrier Y, Waller J, Manson JA, Nairn JA (2009) Models for saturation damage state in multilayer coatings. Mech Mater 42:326–334

Levin VM (1967) On the coefficients of thermal expansion in heterogeneous materials. Mech Solids 2:58–61

Lim SH, Li S (2005) Energy release rates for transverse cracking and delaminations induced by transverse cracks in laminated composites. Compos Part A 36:1467–1476

Liu S, Nairn JA (1990) Fracture mechanics analysis of composite microcracking: experimental results in fatigue. In: Proceedings of the american Society of Compsites, 5th Technical Conference, June 11–14, East Lansing, MI, USA, pp 287–295

Matsumoto N, Nairn JA (2012) Fracture toughness of wood and wood composites during crack propagation. Wood Fiber Sci 44(2):121–133

McCartney LN (1993) The prediction of cracking in biaxially loaded cross-ply laminates having brittle matrices. Composites 24:84–92

McCartney LN (2008) Energy methods for fatigue damage modelling of laminates. Compos Sci Technol 68:2601–2615

McCartney LN, Byrne MJW (2001) Energy balance method for predicting cracking in cross-ply laminates during bend deformation. In: Proceedings of 10th International Conference on Fracture (ICF-10), Advances in Fracture Research, 2–6 December, Honolulu, HI, USA

McCartney LN, Pierce C (1997) Stress transfer mechanics for multiple ply laminates for axial loading and bending. In: Proceedings of ICCM-11, Gold Coast, Australia

Mirzaei B, Sinha A, Nairn JA (2016) Measuring and modeling fiber bridging: application to wood and wood composites exposed to moisture cycling. Compos Sci Tech 128:65–74

Nairn JA (1989) The strain energy release rate of composite microcracking: a variational approach. J Compos Mater 23:1106–1129

Nairn JA (1992) Microcracking, microcrack-induced delamination, and longitudinal splitting of advanced composite structures. Tech. rep, NASA Contractor Report, p 4472

Nairn JA (1995) Some new variational mechanics results on composite microcracking. In: Proceedings 10th international conference on composite materials, Vancover, BC, Canada, 1995, vol I, pp 423–430

Nairn JA (1997) Fracture mechanics of composites with residual thermal stresses. J Appl Mech 64:804–810

Nairn JA (1999) Applications of finite fracture mechanics for predicting fracture events in composites. In: Fifth international conference on deformation and fracture of composites, London, UK, March 18-19, 1999, pp 1–10

Nairn JA (2000) Comprehensive composite materials, vol 2, Elsevier Science, Ed. R. Talreja and J.-A. E. Månson, chap Matrix Microcracking in Composites, pp 403–432

Nairn JA (2007) A numerical study of the transverse modulus of wood as a function of grain orientation and properties. Holzforschung 61:406–413

Nairn JA (2010) Polar shear-lag analysis of a composite of concentric cylinders with longitudinal cracks: Application to internal checking in wood. Compos Part A Appl Sci Manuf 41(7):850–858. 10.1016/j.compositesa.2010.02.017, http://www.sciencedirect.com/science/article/B6TWN-4YH56GC-2/2/a2bab0a21976664588b6e14a613df4a7

Nairn JA (2017) Cross-laminated timber properties including effects of non-glued edges and additional cracks. Eur J Wood Prod 75(6):973–983

Nairn JA, Hu S (1992) The initiation and growth of delaminations induced by matrix microcracks in laminated composites. Int J Fract 57:1–24

Nairn JA, Hu S (1994) Damage Mechanics of Composite Materials, Elsevier, Amsterdam, Ed. Ramesh Talreja, chap Micromechanics of damage: a case study of matrix microcracking, pp 187–243

Nairn JA, Kim SR (1992) A fracture mechanics analysis of multiple cracking in coatings. Engr Fract Mech 42:195–208

Nairn JA, Hu S, Bark JS (1993) A critical evaluation of theories for predicting microcracking in composite laminates. J Mat Sci 28:5099–5111

O’Brien TK (1984) Mixed-mode strain-energy-release rate effects on edge delamination of composites. Eff Defects Compos Mater ASTM STP 836:125–142

O’Brien TK (1985) Delamination and debonding of materials, vol STP 876, ASTM, Ed. W. S. Johnson, chap analysis of local delaminations and their influence on composite behavior, pp 282–297

Oh JK, Lee JJ, Hong JP (2015) Prediction of compressive strength of cross-laminated timber panel. J Wood Sci 61(1):28–34

Pang S, Orchard R, McConchie D (1999) Tangential shrinkage of pinus radiata earlywood and latewood, and its implication for within-ring internal checking. N Z J For Sci 29(3):484–491

Paris PC, Gomez RE, Anderson WE (1961) A rational analytical theory of fatigue. Trend Eng 13:9–14

Parvizi A, Garrett KW, Bailey JE (1978) Constrained cracking in glass fiber-reinforced epoxy cross-ply laminates. J Mat Sci 13:195–201

Reiterer A, Stanzl-Tschegg S, Tschegg E (2000) Mode I fracture and acoustic emission of softwood and hardwood. Wood Sci Technol 34(5):417–430

Salpekar SA, O’Brien TK (1991) Analysis of matrix cracking and local delamination in (0/\(\theta\)/-\(\theta\))s graphite epoxy laminates under tension load. In: Proceedings of 8th International Conference on Composite Materials Honolul, HI, USA, 28-G:1–14

Schniewind AP, Centeno JC (1973) Fracture toughness and duration of load factor I. six principal systems of crack propagation and the duration fractor for cracks propagating parallel to grain. Wood Fiber 5:152–159

Shir Mohammadi M, Nairn JA (2014) Crack propagation and fracture toughness of solid balsa used for cores of sandwich composites. J Sandw Struct Mater 16(1):22–41

Williams JG (1984) Fracture mechanics of polymers. Wiley, New York

Wilson E, Shir Mohammadi M, Nairn JA (2013) Crack propagation fracture toughness of several wood species. Adv Civil Eng Mater 2(1):316–327

Zabel RA, Morrell JJ (2012) Wood microbiology: decay and its prevention. Academic press, Cambridge

Acknowledgements

This work was made possible by the endowment for the Richardson Chair in Wood Science and Forest Products.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Nairn, J.A. Predicting layer cracks in cross-laminated timber with evaluations of strategies for suppressing them. Eur. J. Wood Prod. 77, 405–419 (2019). https://doi.org/10.1007/s00107-019-01399-7

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-019-01399-7