Abstract

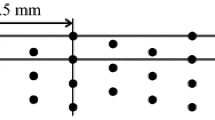

In order to clarify the processing characteristics of wood by UV laser and to improve the processing speed of laser micro incising, the influences of pulse repetition rate and pulse energy of the laser on processing efficiency were investigated. As a result, it was found that each parameter combined affects the processing efficiency and processing form of wood. Based on the optimum processing conditions obtained there, two processing methods, dispersed irradiation method and concentrated irradiation method, were proposed for the laser micro incising. The dispersed irradiation method was considered to be suitable for conditions with high incision density. On the other hand, the concentrated irradiation method was considered to be suitable for cases where absolute hole depth is required or conditions with relatively low incision density. By selecting the processing method appropriately, a possibility of improving the processing speed was found.

Similar content being viewed by others

References

Fukuta S, Nomura M, Ikeda T, Yoshizawa M, Yamasaki M, Sasaki Y (2016a) UV laser machining of wood. Euro J Wood Prod 74(2):261–267

Fukuta S, Nomura M, Ikeda T, Yoshizawa M, Yamasaki M, Sasaki Y (2016b) Wavelength dependence of machining performance in UV-, VIS- and NIR-laser cutting of wood. J Wood Sci 62(4):316–323

Fukuta S, Nomura M, Wakabayashi K (2017) Laser micro incising for adding functionality to wood by chemical modification. In: Proceedings of the 88th Laser Materials Processing Conference. p. 28–35 (in Japanese)

Fukuta S, Nomura M, Ikeda T, Yoshizawa M, Yamasaki M, Sasaki Y (2018) UV-laser incisions to apply wood-plastic compositions to wood surfaces. Mokuzai Gakkaishi 64(1):28–35 (in Japanese)

Hattori N (1995) Laser processing of wood. Mokuzai Gakkaishi 41(8):703–709 (in Japanese)

Nomura M, Fukuta S (2018) Vapor phase acetylation of wood using UV-laser incisions. Wood Industry 73(1):8–12 (in Japanese)

Ooie T, Miyamoto I (1996) Characteristics of excimer laser-induced iron plasma. Fundamental research of materials processing by excimer laser, report 1. J Japan Welding Soc 14(3):489–494 (in Japanese)

Raylase GmbH (2018) Ultra-high-speed scanner. https://www.raylase.de/de/produkte/2-achsen-ablenkeinheiten/ultra-high-speed-scanner.html. Accessed 2 May 2018

Acknowledgements

This research was partially supported by the Matching Planner Program from Japan Science and Technology Agency, JST.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Fukuta, S., Nomura, M., Ikeda, T. et al. Processing characteristics of laser micro incising and possibility of its high speed processing. Eur. J. Wood Prod. 77, 249–255 (2019). https://doi.org/10.1007/s00107-019-01384-0

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-019-01384-0