Abstract

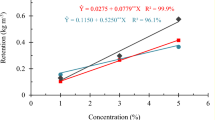

Two phenol–formaldehyde resols, namely a low and a medium molecular weight phenol–formaldehyde, were investigated for their applicability as plasticizers in moulding of European beech veneer (Fagus sylvatica L.). Therefore, beech veneers specimens were impregnated with both phenol–formaldehyde resol types in various concentrations. Subsequently, two-dimensional mouldability of the veneer was tested in a three-point-bending test along and perpendicular to the grain. Additionally, three-dimensional moulding of the phenol–formaldehyde impregnated veneer was tested throughout a modified Erichsen cupping test, where the veneer is pressed through a circular shaped coining die. The obtained results indicate a significantly improved mouldability of the treated beech veneers compared to untreated, water-saturated control specimens. Even at low phenol–formaldehyde concentrations plasticizing effects were detected in longitudinal direction and perpendicular to the grain. These findings are substantiated by results from three-dimensional moulding. Furthermore, the low molecular weight phenol–formaldehyde treated veneers displayed a higher mouldability than medium molecular weight phenol–formaldehyde specimens at similar phenol–formaldehyde concentration.

Similar content being viewed by others

References

Beery WH, Ifu G, McLain TE (1983) Quantitative wood anatomy—relating anatomy to transverse tensile strength. Wood Fiber Sci 15(4):395–407

Biziks V, Bicke S, Militz H (2015) Penetration of phenol formaldehyde (PF) resin into beech wood studied by light microscopy. In: Annual Meeting of International Research group on Wood Protection, Vina del Mar, Chile. IRG/WP 15-20558

Buchelt B, Wagenführ A (2008) The mechanical behaviour of veneer subjected to bending and tensile loads. Holz Roh Werkst 66:289–294

Davidson RW, Baumgardt WG (1970) Plasticizing wood with ammonia—a progress report. For Prod J 20(3):1925

DIN 50101, issue 1979-09 (withdrawn) Testing of metals; Erichsen cupping test on sheet and strip metal having a width of ≥ 90 mm; Thickness range: 0.2 to 2 mm. German Institute for Standardization

DIN 52186-06 (1978) Testing of wood; bending test (in German). German Institute for Standardization

Fekiac J, Zemiar J, Gaff M, Gabirik J, Gasparik M, Marusak R (2015) 3D-moldability of veneers plasticized with water and ammonia. BioResources 10(1):866–876

Franke T, Mund A, Lenz C, Herold N, Pfriem A (2017) Microscopic and macroscopic swelling and dimensional stability of beech wood impregnated with phenol-formaldehyde. Pro Ligno 13(4):373–378

Furuno T, Imamura Y, Kajita H (2004) The modification of wood by treatment with low molecular weight phenol-formaldehyde resin: a properties enhancement with neutralized phenolic-resin and resin penetration into wood cell walls. Wood Sci Technol 37:349–361

Gabrielli CP, Kamke FA (2010) Phenol-formaldehyde impregnation of densified wood for improved dimensional stability. Wood Sci Technol 44:95–104

Gasparik M, Barcik S (2013) Impact of plasticization by microwave heating on the total deformation of beech wood. BioResources 8(4):62976308

Gasson P (1987) Some implications of anatomical variations in the wood of pedunculate oak (Quercus robur L.), including comparisons with common beech (Fagus sylvatica L.). IAWA Bull 8(2):149–166

Herold N, Pfriem A (2013) Impregnation of veneer with furfuryl alcohol for an improved plasticization and moulding. Eur J Wood Prod 71(2):281–282

Herold N, Pfriem A (2014) Shape retention of furfurylated and moulded wood veneer. BioResources 9(1):545 553

Huang Y, Fei B, Zhao R (2014) Investigations of low-molecular weight phenol formaldehyde distribution in tracheid cell walls of Chinese fir wood. BioResources 9(3):41504158

Huttunen J (1975) Method for plasticizing wood. US 3,894,569

Jebrane M, Harper D, Labbé N, Sèbea G (2011) Comparative determination of the grafting distribution and viscoelastic properties of wood blocks acetylated by vinyl acetate or acetic anhydride. Carbohydr Polym 84:1314–1320

Kelley SS, Rials TG, Glasser WG (1987) Relaxation behaviour of the amorphous components of wood. J Mater Sci 22:617–624

Knop A, Pilato LA (1985) Phenolic resins. Chemistry, applications and performance—future directions. Springer, Berlin

Loughborough WK (1942) Process for plasticizing lignocellulosic materials. US 2,298,017 A

Norimoto M, Gril J (1989) Wood bending using microwave heating. J Microwave Power EE 24(4):203–212

Pfriem A, Dietrich T, Buchelt B (2012) Furfuryl alcohol impregnation for improved plasticization and fixation during densification of wood. Holzforschung 66:215–218

Pizzi A (2003) Phenolic resins. In: Pizzi A, Mittal KL (eds) Handbook of adhesive technology, 2nd edn. Taylor & Francis, New York

Sadoh T (1981) Viscoelastic properties of wood in swelling systems. Wood Sci Technol 15:57–66. https://doi.org/10.1007/BF00366501

Sass U, Eckstein D (1995) The variability of vessel size in beech (Fagus sylvatica L.) and its ecophysiological interpretation. Trees 9:247252

Schuerch C (1963) Plasticizing wood with liquid ammonia. Ind Eng Chem 55(10):39

Shams MI, Yano H (2011) Compressive deformation of phenol formaldehyde (PF) resin-impregnated wood related to the molecular weight of resin. Wood Sci Technol 45:73–81

Shams MI, Yano H, Endou K (2004) Compressive deformation of wood with low molecular weight phenol formaldehyde (PF) resin I: effects of pressing and pressure holding. J Wood Sci 50:337–342

Sontag LA, Norton J (1935) Phenolic resin adhesives in the plywood industry. Ind Eng Chem 277(10):11141119

Stamm AJ, Seborg RM (1942) Resin treated wood (Impreg) Forest Products Laboratory. Report 1380 (Revised 1962)

Stamm AJ, Seborg RM (1955) Resin-treated, laminated compressed wood (Compreg). Forest Products Laboratory. Report 1381 (Revised 1960)

Wagenführ A, Buchelt B, Pfriem A (2006) Material behaviour of veneer during multidimensional moulding. Holz Roh Werkst 64:83–89

Acknowledgements

The authors gratefully acknowledge the German Federal Ministry for Education and Research (BMBF) for the financial support (Grant number 13FH001PX4). Furthermore, we like to acknowledge Prefere Resins® Germany GmbH Erkner for providing the PF resins.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Franke, T., Herold, N., Buchelt, B. et al. The potential of phenol–formaldehyde as plasticizing agent for moulding applications of wood veneer: two-dimensional and three-dimensional moulding. Eur. J. Wood Prod. 76, 1409–1416 (2018). https://doi.org/10.1007/s00107-018-1320-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-018-1320-1