Abstract

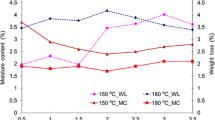

European beech (Fagus sylvatica) wood specimens were subjected to thermo-mechanical densification, and the influence of pressing parameters on dimensional stability, mean density and density profiles was evaluated. The specimens with two initial moisture contents, 18% and the fibre saturation point, were compressed by 20 and 40% at temperatures of 160, 180, 200, and 220 °C for several times, specified in the Methods, ranging from 6 to 12 min. Dimensional changes were observed immediately after the removal from the hot press and subsequent conditioning (20 °C, 65% relative humidity). The properties of the compressed beech wood were influenced by all the pressing parameters. This influence, however, varied based on the factor and property. The analysis showed as most appropriate: an initial moisture content ranging from 17 to 20%, a pressing temperature ≥ 180 °C and pressing time ≥ 10 min for the given thickness. As for the compression degree, it is necessary to consider the purpose of compression and the wood properties required.

Similar content being viewed by others

References

Babiak M, Kúdela J (1995) A contribution to the definition of the fiber saturation point. Wood Sci Technol 29:217–226

Bächle F, Niemz P, Schneider T (2007) Physical-mechanical properties of hard- and softwood heat treated in an Autoclave. In: Hill CAS, Jones D, Militz H, Ormondroyd GA (eds) European conference on wood modification processing 2007 Biocomposites Centre. University of Wales, Bangor, pp 177–182

Bahýl V (1992) Device for density profile analysis of wood based materials. (Analyzátor hustotného profilu aglomerovaných materiálov). Drevo 47(1):48–49

Barna M, Kulfan J, Bublinec E et al (2011) Beech and beech ecosystems of Slovakia. VEDA, Bratislava

Blomberg J (2006) Mechanical and physical properties of semi-isostatically densified wood. Dissertation, Luleå University of Technology

Blomberg J, Persson B, Bexell U (2006) Effects of semi-isostatic densification on anatomy and cell shape recovery on soaking. Holzforschung 60:322–331

Chuchrjanskij PN (1953) Wood compression (Lisovanie dreva). Práca, Bratislava

Dwianto W, Morooka T, Norimoto M, Kitajima T (1999) Stress relaxation of sugi (Cryptomeria japonica, D. Don) wood in radial compression under high temperature steam. Holzforschung 53:541–546

Esteves BM, Pereira HM (2009) Wood modification by heat treatment. BioResources 4:370–404

Hatakeyama H, Iwashita K, Meshitsuka G, Nakano J (1975) Effect of molecular weight on glass transition temperature of lignin. Mokuzai Gakkaishi 21:618–623

Inoue M, Kodama J, Yamamoto Y, Norimoto M (1998) Dimensional stabilization of compressed wood using high-frequency heating. Mokuzai Gakkaishi 44:410–416

Irvine GM (1984) The significance of the glass transition of lignin and hemicelluloses and their measurement by differential thermal analysis. Tappi J 67:118–121

ISO 13061-1 (2014) Physical and mechanical properties of wood—test methods for small clear wood specimens—Part 1: determination of moisture content for physical and mechanical tests. International Organization for Standardization, Geneva

ISO 13061-2 (2014) Physical and mechanical properties of wood—test methods for small clear wood specimens—part 2: determination of density for physical and mechanical tests. International Organization for Standardization, Geneva

Ito Y, Tanahashi M, Shigematsu M, Shinoda Y, Ohta Ch (1998a) Compressive-moulding of wood high pressure steam-treatment. Part 1. Development of compressively moulded squares from thinnings. Holzforschung 52:211–216

Ito Y, Tanahashi M, Shigematsu M, Shinoda Y (1998b) Compressive-moulding of wood high-pressure steam-treatment. Part 2. Mechanism of permanent fixation. Holzforschung 52:217–221

Johansson D, Persson M, Morén T (2006) Effect of heat treatment on capillary water absorption of heat-treated pine, spruce and birch. In: Kurjatko S et al (eds) 5th IUFRO symposium wood structure and properties’06. Arbora, Zvolen, pp 251–255

Kačík F (1997) Influence of temperature and moisture on alternations of wood saccharides. Technical University in Zvolen, Zvolen

Kačíková D, Kačík F (2011) Chemical and mechanical changes of wood during thermal treatment (Chemické a mechanické zmeny dreva pri termickej úprave). Technical University in Zvolen, Zvolen

Král P, Klímek P, Mishra PK, Wimmer R, Děcký D (2015) Specific Modulus and Density Profile as Characterization Criteria of Prefabricated Wood Composite Materials. Acta Universitatis Agriculturae et Silviculturae Mendelianae Brunensis 63(2):433–438

Kubo S, Ishikava N, Uraki Y, Sano Y (1997) Preparation of lignin fibers from softwood acetic acid lignin. Relationship between fusibility and the chemical structure of lignin. Mokuzai Gakkaishi 43:655–662

Kúdela J (2005) Moisture and heat loading of beech wood (Vlhkostné a tepelné namáhanie bukového dreva). Technical University in Zvolen, Zvolen

Kúdela J (2010) Mechanical properties of wood (Mechanické vlastnosti dreva). In: Kurjatko S (ed) Parametre kvality dreva určujúce jeho finálne použitie. Technical University in Zvolen, Zvolen, pp 101–127

Kúdela J, Čunderlík I (2012) European beech wood—structure, properties and use (Bukové drevo—štruktúra, vlastnosti a použitie). Technical University in Zvolen, Zvolen

Kúdela J, Rešetka M (2012) Influence of pressing parameters on dimensional stability and selected properties of pressed beech wood. I. Dimensional stability and density. Acta Facultatis Xylologiae 54(1):15–24

Kúdela J, Rešetka M (2013) Influence of pressing parameters on dimensional stability and selected properties of beech wood. II. Density profile and hardness. Acta Facultatis Xylologiae 55(1):41–49

Kutnar A, Kamke FA (2012) Influence of temperature and steam environment on set recovery of compressive deformation of wood. Wood Sci Technol 46(5):953–964

Kutnar A, Kamke FA, Sernek M (2008) Density profile and morphology of viscoelastic thermal compressed wood. Wood Sci Technol 43:57–68

Li L, Gong M, Yuan N, Li D (2013) An optimal thermo-hydro-mechanical densification (THM) process for densifying balsam fir wood. BioResources 8(3):3967–3981

Li L, Wang X, Wu F (2016) Chemical analysis of densification, drying, and heat treatment of scots pine (Pinus sylvestris L.) through a hot-pressing process. BioResources 11(2):3856–3874

Navi P, Girardet F (2000) Effect of thermo-hydro-mechanical treatment on the structure and properties of wood. Holzforschung 54:287–293

Navi P, Sandberg D (2012) Thermo-hydro-mechanical wood processing. CRC, Boca Raton

Norimoto M, Ota C, Akitsu H, Yamada T (1993) Permanent Fixation of Bending Deformation in Wood by Heat Treatment. Wood Research 79:23–33

Olson AM, Salmén L (1997) Humidity and temperature affecting hemicellulose softening of wood. Int Conf COST Act sE 8:267–279

Pelit H, Budakçı M, Sönmez A (2016) Effects of heat post-treatment on dimensional stability and water absorption behaviours of mechanically densified Uludağ fir and black poplar woods. BioResources 11(2):3215–3229

Pizzi A, Eaton NJ, Bariska M (1987a) Theoretical water sorption energies by conformational analysis. Part. 1.: crystalline cellulose I. Wood Sci Technol 21:235–248

Pizzi A, Bariska M, Eaton NJ (1987b) Theoretical water sorption energies by conformational analysis. Part. 2. Amorphous cellulose and the sorption isotherm. Wood Sci Technol 21:317–327

Popescu MC, Lisa G, Froidevaux J, Navi P, Popescu CM (2014) Evaluation of the thermal stability and set recovery of thermo-hydro-mechanically treated lime (Tilia cordata) wood. Wood Sci Technol 48(1):85–97

Rautkari L, Laine K. Laflin N, Hughes M (2011) Surface modification of Scots pine: the effect of process parameters on the through thickness density profile. J Mater Sci 46:4780–4786

Rautkari L, Laine K, Kutnar A, Medved S, Hughes M (2013) Hardness and density profile of surface densified and thermally modified Scots pine in relation to degree of densification. J Mater Sci 48(6):2370–2375

Rešetka M (2013) Changes in wood during compression at various temperatures and moisture contents (Zmeny v dreve v procese lisovania za rôznych teplotných a vlhkostných podmienok). Dissertation, Technical University in Zvolen

Rešetka M, Kúdela J (2013) Influence of pressing parameters on dimensional stability and density. In: Kúdela J, Babiak M (eds) Wood the best material for mankind. Arbora, Zvolen, pp 49–57

Seborg RM, Millett MA, Stamm AJ (1962) Heat-stabilized compressed wood. FPL, Report No. 1580

Solár R (1997) Changes of lignin in processes of hydrothermal treatment. (Zmeny lignínu v procesoch hydrotermickej úpravy. Technical University in Zvolen, Zvolen

Stamm AJ, Seborg RM (1941) Resin treated, laminated, compressed wood. Trans Am Inst Chem Eng 37:385–397

Tjeerdsma BF, Militz H (2005) Chemical changes in hydrothermal treated wood: FTIR analysis of combined hydrothermal and dry heat-treated wood. Holz Roh-Werkst 63(2):102–111

Tu D, Su X, Zhang T, Fan W, Zhou Q (2014) Thermo-mechanical densification of Populus tomentosa var. tomentosa with low moisture content. BioResources 9(3):3846–3856

Tuong VM, Li J (2011) Changes caused by heat treatment in chemical composition and some physical properties of acacia hybrid sapwood. Holzforschung 65:67–72

Wang JY, Cooper PA (2005) Effect of grain orientation and surface wetting on vertical density profiles of thermally compressed fir and spruce. Holz Roh-Werkst 63:397–402

Wang S, Winistorferf PM (2000) Fundamentals of vertical density profile formation in wood composites. Part II. Methodology of vertical density formation under dynamic conditions. Wood Fiber Sci 32(2):220–238

Welzbacher CR, Wehsener J, Rapp AO, Haller P (2008) Thermo-mechanical densification combined with thermal modification of Norway spruce (Picea abies Karst) in industrial scale-dimensional stability and durability aspects. Eur J Wood Prod 66(1):39–49

Young RA (1978) Thermal transitions of wood polymers by torsional pendulum analysis. Wood Sci 11:97–101

Acknowledgements

This work was funded by the following: the Scientific Grant Agency of the Ministry of Education SR and the Slovak Academy of Sciences (Grant no. 1/0822/17 “Surface modification of wood and coating materials in order to improve stability of the wood-coating material system”), and supported by the Specific University Research Fund of the FFWT Mendel University in Brno (LDF_PSV_2016015).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kúdela, J., Rousek, R., Rademacher, P. et al. Influence of pressing parameters on dimensional stability and density of compressed beech wood. Eur. J. Wood Prod. 76, 1241–1252 (2018). https://doi.org/10.1007/s00107-018-1298-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-018-1298-8