Abstract

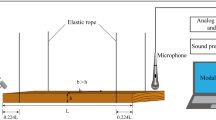

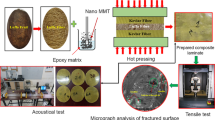

Although ultra-low density fiberboards (ULDFs) have good sound and thermal insulation performance, formaldehyde emission in the manufacturing process and in the subsequent use of the products limits their field of application. The objective of this study was to employ an unsaturated polyester resin (UPR) in the manufacturing of the boards as a substitute of formaldehyde-based adhesives in order to develop environment-friendly ULDFs. The effects of UPR dosage, fiber treatment agent, press time and fiber consumption on the properties of fiberboards were studied. Sound absorption and thermal conductivity were also measured to ensure sound and thermal insulation properties of the fiberboards. Board density, modulus of rupture and thickness swelling in 2 h were 320 kg/m3, 4.14 MPa and 3.75%, respectively, under optimal conditions such as 12% UPR dosage, 1% fiber treatment agent, 400 g fiber consumption and 210 s press time. Noise reduction coefficient and thermal conductivity of the boards were found within a range of 0.68–0.58 and 0.038–0.048 W/(m K), respectively, while the density of boards ranged from 150 to 400 kg/m3. Therefore, sound absorption property of the fiberboards developed in this study satisfies the requirement of high-efficiency sound absorption materials, which is close to the value (0.67) of ULDF having a density of 56.3 kg/m3 obtained by a wet process. Thermal insulation property of boards was close to that of commonly used insulation materials such as rock wool [0.036 W/(m K)] and glass fiber [0.045 W/(m K)]. In conclusion, fiberboards can be used for non-structural furniture materials, sound and thermal insulation materials in buildings because of their environmental friendliness, good mechanical properties, and excellent sound and thermal insulation properties.

Similar content being viewed by others

References

Chen TT (2014) Study on the modification, characterization and properties of hemp fibers reinforced unsaturated polyester composites. Dissertation, Fujian Agr and Forestry U

Chen JY (2015) Study on sound absorption of ultra-low density plant fiber material. Dissertation, Fujian Agr and Forestry U

Chirayil CJ, Joy J, Mathew L, Koetz J, Thomas S (2014) Nanofibril reinforced unsaturated polyester nanocomposites: morphology, mechanical and barrier properties, viscoelastic behavior and polymer chain confinement. Ind Crop Prod 56(3):246–254

GB/T 10297-1998 (1998) Plan name in English test method for thermal conductivity of nonmetal solid materials by hot-wire method. State Bureau of Quality Technical Supervision, Beijing

GB/T 16731-1997 (1997) The graduation of sound absorption property for absorbent products. Standardization administration of the People’s Republic of China, Beijing

GB/T 17657-2013 (2013) Test methods of evaluating the properties of wood-based panels and surface decorated wood-based panels. General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China & Standardization administration of the People’s Republic of China, Beijing

GB/T 18696.1-2004 (2004) Acoustics-determination of sound absorption coefficient and impedance in impedance tubes-part 1: method using standing wave ratio, General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China; Standardization administration of the People’s Republic of China, Beijing

Huang YT, Wang X, Jiang FC (2003) Experimental production of ultra-light medium density fiberboard from Chinese Fir. China For Prod Ind 30:15–17

ISO 16895: 2016 (2016) Wood-based panels—dry-process fibreboard. International Organization for Standardization, Geneva, Switzerland

Kawasaki T, Zhang M, Kawai S (1998) Manufacture and properties of ultra-low-density fiberboard. J Wood Sci 44:354–360

Lavoratti A, Scienza LC, Zattera AJ (2016) Dynamic-mechanical and thermomechanical properties of cellulose nanofiber/polyester resin composites. Carbohyd Polym 136:955–963

Lian YY, Feng GZ, Liao LW (2009) Research advances in modification of unsaturated polyester resin. Guangdong Chem Ind 36:78–80

Liao R, Xu JY, Tang ZY, Zhong Z, Wu XF, You Y (2015) Study on ultra-low density bagasse binderless particleboard. J Cent South U For Technol 35:109–113

LY/T 1718-2007 (2007) Ultra-low density fiberboards. State Forestry Bureau, Beijing

Ma Y (2006) Exploring the processing technology for low density boards with micro-wood fiber. China Wood Ind 20:19–21

Rowell RM, Kawai S, Inoue M (2007) Dimensionally stabilized, very low density fiberboard. Wood Fiber Sci 27:428–436

Saheb DN, Jog JP (1999) Natural fiber polymer composites: a review. Adv Polym Technol 18:351–363

Shen K (2005) Unsaturated polyester resin and its application (third editor). Chem Ind Press, Beijing

Shen YY (2014) Preparation and performance of PET fibers and bamboo fibers reinforced unsaturated polyester hybrid composites. Dissertation, Fujian Agriculture and Forestry University

Tarnami K, Zhang M, Kawai S (1999) Sandwich panel of veneer-overlaid low-density fiberboard. J Wood Sci 45:291–298

Vilay V, Mariatti M, Taib RM, Todo M (2008) Effect of fiber surface treatment and fiber loading on the properties of bagasse fiber-reinforced unsaturated polyester composites. Compos Sci Technol 68:631–638

Xie YQ, Tong QJ, Chen Y, Liu JH, Lin M (2011) Manufacture and properties of ultra-low density fibreboard from wood fibre. Bio Res 6:4055–4066

Xu JY, Widyorini R, Yamauchi H, Kawai S (2006) Development of binderless fiberboard from kenaf core. J Wood Sci 52:236–243

Zhang WM, Dong BX, Xu HL (2004) Study on the modification of unsaturated polyesters/polyurethanes. China Elastom 14:26–29

Acknowledgements

The authors thank Fujian Yongyue Science and Technology Co., Ltd. for the kind supply of UPR, TDI and MEMK, and associate professor Qingping Zhuang for assistance with the experiments. This work is supported by the project named “Preparation and Industrialization of Ultra-low Density Engineering materials Using Plant Fiber as the matrix” (Grant No. 119/K52136003).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Niu, M., Wu, Z., Lin, X. et al. Manufacturing and properties of ultra-low density fiberboards with an unsaturated polyester resin by a dry process. Eur. J. Wood Prod. 76, 853–859 (2018). https://doi.org/10.1007/s00107-017-1252-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-017-1252-1