Abstract

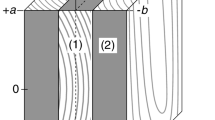

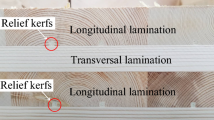

Cross laminated timber (CLT) is usually comprised of multiple timber layers having alternating grain directions. Because individual boards are glued on their faces between layers, but usually not glued on their edges within layers, those edges define “precracks” in the composite. When exposed to differential thermal and moisture expansion after installation, CLT, like all cross-laminated composites, is prone to formation of “additional cracks”. Confidant CLT design must be able to account for changes in CLT properties during life of a structure caused by such additional cracks. By extending variational mechanics methods for aerospace composites, this paper provides analytical solutions for all in-plane mechanical, thermal expansion, and moisture expansion properties of a three-layer CLT panel. By using the three-layer solution to evaluate effective layer properties as a function of the number of cracks, the analysis can be extended to in-plane mechanical, out-of-plane bending, and expansion properties for CLT panels with any number or arrangement of layers. Some sample calculations are provided along with comments on limitations of the approximations and needs for future work.

Similar content being viewed by others

References

Allen DH (1994) Damage evolution in laminates. In: Talreja R (ed) Damage mechanics of composite materials. Elsevier, Amsterdam, pp 79–116

Bogensperger T, Moosbrugger T, Silly G (2010) Verification of CLT-plates under loads in plane. In: World conference on timber engineering, Riva del Garda, Italy, pp June 20–24

Christenson RM (1979) Mechanics of composite materials. Wiley, New York

Frost SR (1994) The impact behaviour and damage tolerance of filament would glass fibre/epoxy matrix pipes. In: 6th international conference on of fiber-reinforced composites, University of Newcastle upon Tyne, March 29–31, vol 3, pp 1–10

Gibson LJ, Ashby MF (1997) Cellular solids: structure and properties. Cambridge University Press, Cambridge

Hashin Z (1985) Analysis of cracked laminates: a variational approach. Mech Mater 4:121–136

Hashin Z (1986) Analysis of stiffness reduction of cracked cross-ply laminates. Eng Fract Mech 25:771–778

Hashin Z (1987) Analysis of orthogonally cracked laminates under tension. J Appl Mech 54:872–879

Hashin Z (1988) Thermal expansion coefficients of cracked laminates. Comp Sci Technol 31:247–260

Hashin Z (1990) Thermoelastic properties of fiber composites with imperfect interface. Mech Mater 8:333–348

Hashin Z (1992) Extremum principles for elastic heterogenous media with imperfect interfaces and their application to bounding of effective moduli. J Mech Phys Solids 40(4):767–781

Hashin Z (2010) Shear modulus of orthongally crack laminates, personal communication

Jones RM (1975) Mechanics of composite materials. Scripta Book Company, Washington, DC

Kim SR, Nairn JA (2000a) Fracture mechanics analysis of coating/substrate systems subjected to tension or bending loads I: theory. Engr Fract Mech 65:573–593

Kim SR, Nairn JA (2000b) Fracture mechanics analysis of coating/substrate systems subjected to tension or bending loads II: experiments in bending. Engr Fract Mech 65:595–607

Levin VM (1967) On the coefficients of thermal expansion in heterogeneous materials. Mech Solids 2:58–61

McCartney LN (1993) Stress transfer mechanics for multiple perfectly bonded concentric cylinder models of unidirectional composites. National Physical Lab Report DMM(A), p 129

McCartney LN (1997) Predicting steady state delamination in a cross-ply laminate subject to through-thickness pressure. NPL Report CMMT(A), p 65

Nairn JA (1989) The strain energy release rate of composite microcracking: a variational approach. J Comp Mater 23:1106–1129

Nairn JA (2000) Matrix microcracking in composites. In: Talreja R, Manson JAE (eds) Comprehensive composite materials, vol 2. Elsevier Science, Amsterdam, pp 403–432

Nairn JA (2007) A numerical study of the transverse modulus of wood as a function of grain orientation and properties. Holzforschung 61:406–413

Nairn JA (2013) Modeling of imperfect interfaces in the material point method using multimaterial methods. Comput Model Eng Sci 92(3):271–299

Nairn JA (2016a) Material point method (NairnMPM) and finite element analysis (NairnFEA) open-source software. http://osupdocs.forestry.oregonstate.edu/index.php/Main_Page

Nairn JA (2016b) Mechanical properties of cross-laminated timber accounting for non-bonded edges and additional cracks. In: World Conference on Timber Engineering, Vienna, Austria, pp August 22–25

Nairn JA, Hu S (1994) Micromechanics of damage: a case study of matrix microcracking. In: Talreja R (ed) Damage mechanics of composite materials. Elsevier, Amsterdam, pp 187–243

Nairn JA, Hu S, Bark JS (1993) A critical evaluation of theories for predicting microcracking in composite laminates. J Mater Sci 28:5099–5111

Parvizi A, Garrett KW, Bailey JE (1978) Constrained cracking in glass fiber-reinforced epoxy cross-ply laminates. J Mater Sci 13:195–201

Sulsky D, Chen Z, Schreyer HL (1994) A particle method for history-dependent materials. Comput Methods Appl Mech Eng 118:179–186

Acknowledgements

This work was made possible by the endowment for the Richardson Chair in Wood Science and Forest Products.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Nairn, J.A. Cross laminated timber properties including effects of non-glued edges and additional cracks. Eur. J. Wood Prod. 75, 973–983 (2017). https://doi.org/10.1007/s00107-017-1202-y

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-017-1202-y