Abstract

This study was carried out in order to determine the efficacy of microwave (MW) plasticization for wood densification purposes. The plasticization process was carried out using a continuous feed laboratory MW at a frequency of 2.45 GHz. European beech (Fagus sylvatica L.) specimens measuring 50 mm × 40 mm × 8 mm were MW treated (plasticized) with an output of 3.5 kW at a conveyor speed of 0.4 m/min. Afterwards, MW plasticized specimens were densified with a ratio of 50%. Microscopic structure changes of densified wood were detected using a scanning electron microscope (SEM) and density profiles were measured using the X-ray densitography. An average density of 677 kg m−3 and 771 kg m−3 increased significantly to 951 kg m−3 for radially densified and to 1194 kg m−3 for tangentially densified specimens. X-ray densitography results show uniformity of density profiles through specimen thickness, which confirmed the evenly plasticized volume of wood. Microscopic structure observation revealed that the MW plasticization was not accompanied by any fractures, and deformations present in the densified wood were due to viscoelastic buckling of cell walls without crack propagation. Therefore, MW treatment can be considered as an effective method for wood plasticization.

Similar content being viewed by others

References

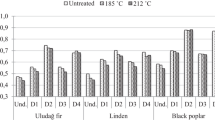

Boonstra M, Blomberg J (2007) Semi-isostatic densification of heat-treated radiata pine. Wood Sci Technol 40(7):607–617

Bouriaud O, Bréda N, Moguédec G, Nepveu G (2004) Modelling variability of wood density in beech as affected by ring age, radial growth and climate. Trees 18(3):264–276

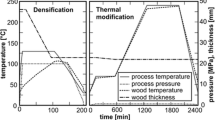

Čermák P, Horáček P, Rademacher P (2013) Heat distribution in thermally modified timber. Eur J Wood Prod 71(6):827–830

Čermák P, Rautkari L, Horáček P, Saake B, Rademacher P, Sablík P (2015) Analysis of dimensional stability of thermally modified wood affected by re-wetting cycles. BioResources 10(2):3242–3253

Dömény J, Koiš V, Zapletal M (2014) Application of microwave treatment for the plasticization of beech wood (Fagus sylvatica L.) and its densification for flooring system purposes. BioResources 9(4):7519–7528

EN 13183-1 (2002) Moisture content of a piece of sawn timber—Part 1: Determination by oven dry method. European Committee for Standardization, Brussels, Belgium

Fang CH, Mariotti N, Cloutier A, Koubaa A, Blanchet P (2012) Densification of wood veneers by compression combined with heat and steam. Eur J Wood Prod 70(1–3):155–163

Fukuta S, Asada F, Sasaki Y (2008) Manufacture of compressed wood fixed by phenolic resin impregnation trough drilled holes. J Wood Sci 54(2):100–106

Gabrielli C, Kamke FA (2008) Treatment of chemically modified wood with VTC process to improve dimensional stability. Forest Prod J 58(12):82–86

Gašparík M, Gaff M (2013) Changes in temperature and moisture content in beech wood plasticized by microwave heating. BioResources 8(3):3372–3384

Hansson L, Antti AL (2003) The effect of microwave drying on Norway spruce woods strength: a comparison with conventional drying. J Mater Process Tech 141(1):41–50

Haygreen J, Bowyer J (1996) Forest products and wood science, 3rd edn. Iowa State University Press. ISBN: 0-81382-256-4

Higashihara T, Morooka T, Norimoto M. (2000) Permanent fixation transversely compressed wood by steaming and its mechanism. Mokuzai Gakkaishi 46(4):291–297

Hill CA (2006) Wood modification: chemical, thermal and other processes. John Wiley and Sons, West Sussex

Hill CA, Jones D (1996) The dimensional stabilisation of Corsican pine sapwood by reaction with carboxylic acid anhydrides. Holzforschung 50(5):457–462

Hillis WE, Rozsa AN (1978) The softening temperatures of wood. Holzforschung 32:68–73

Hong-Hai L, Qing-Wen W, Lin Y, Tao J, Ying-Chun C (2005) Modification of larch wood by intensive microwave irradiation. J For Res 16(3):237–240

Inoue M, Norimoto M, Tanahashi M, Rowell RM (1993) Steam or heat fixation of compressed wood. Wood Fiber Sci 25(3):224–235

Kamke FA (2006) Densified radiate pine for structural composites. Maderas, Ciencia y Technologia 8(2):83–92

Kasal B (1989) Behavior of wood under transverse compression. MS. Thesis, Virginia Polytechnic Institute and State University, Blacksburg, VA, USA

Koiš V, Dömény J, Tippner J (2014) Microwave device for continuous modification of wood. BioResources 9(2):3025–3037

Kollmann FP, Côté W (1968) Principles of wood science and technology. vol. I: Solid Wood. Springer Verlag, Berlin

Kollmann FP, Kuenzi EW, Stamm AJ (1975) Principles of wood science and technology. Vol. II Wood based materials. Springer-Verlag, New York Heidelberg Berlin, pp 139–149

Kutnar A, Kamke FA, Sernek M (2009) Density profile and morphology of viscoelastic thermal compressed wood. Wood Sci Technol 43:57–68

Lamason C, Gong M (2007) Optimization of pressing parameters for mechanically surface-densified aspen. For Prod J 57(10):64–68

Leiker M, Aurich K, Adamska MA (2005) Accelerated drying of single hardwood boards by combined vacuum-microwave application. 9th Intl. IUFRO Wood Drying Conf. Nanjing, China: 185–190

Machado JP (2006) Effect of microwave treatment on oak compression strength. Silva Lusitana, Lisboa, Portugal 14(1):51–58

Makovíny I (2000) Dielectric and electromagnetic characteristics of beech wood. Wood Research 45(3): 23–34

Merenda L, Holan J (2008) The permeability of microwave treated wood for distilled water. Acta Universitatis Agriculturae et. Silviculturae Mendelianae Brunensis 56(1):137–142

Metaxas A, Meredith R (1983) Industrial microwave heating. P. Peregrinus on behalf of the Institution of Electrical Engineers, London, UK, ISBN 0906048893

Militz H (2002) Heat treatment technologies in Europe: Scientific background and technological state of art. Proceedings of Conference on Enhancing the durability of lumber and Engineered Wood Products, Forest Products Society, Madison, USA

Morsing N (2000) Densification of wood—the influence of hygrothermal treatment on compression of beech perpendicular to the grain. Ph.D. thesis, Technical University of Denmark, Department of Structural Engineering and Materials, p 138

Norimoto M, Gril J (1989) Wood bending using microwave heating. J Microwave Power EE 24(4):203–212

Oloyede A, Groombridge P (2000) The influence of microwave rating on the mechanical properties of wood. J Mater Process Technol 100(1):67–73

Rautkari R (2012) Surface modification of solid wood using different techniques. Ph.D. thesis, Department of forest products technology. Aalto University, Helsinki ISBN 9789526044644

Rautkari L, Kutnar A, Hughes M, Kamke FA (2010) Wood surface densification using different methods. In: Proceedings of the 11th World Conference on Timber Engineering, Riva del Garda, Italy

Rautkari L, Laine K, Laflin N, Hughes M (2011) Surface modification of Scots pine: the effect of process parameters on the through thickness density profile. J Mater Sci 46(14):4780–4786

Rowell RM (2005) Chemical modification of wood. In: Rowell RM (ed) Handbook of Wood chemistry and wood composites. CRC Press, Florida, pp 381–420

Seyfarth R, Leiker M, Mollekopf N (2003) Continuous drying of lumber in a microwave vacuum kiln. In: Proceedings of the 8th International IUFRO Wood Drying Conference, Brasov, Romania, pp 159–163

Skyba O, Schwarze FWMR, Niemz P (2009) Physical and mechanical properties of thermo-hygro-mechanically (THM)—densified wood. Wood Res 54(2):1–18

Torgovnikov GI (1993) Dielectric properties of wood and wood-based materials. Springer-Verlag, Berlin. doi:10.1007/978-3-642-77453-9

Torgovnikov GI, Vinden P (2009) High intensity microwave wood modification for increasing permeability. Forest Prod J 59(4):84–92

Tu D, Su X, Zhang T, Fan W, Zhou Q (2014) Thermo-mechanical densification of Populus tomentosa var. tomentosa with low moisture content. BioRes. 9(3):3846–3856

Uhmeir A, Morooka T, Norimoto M (1998) Influence of thermal softening and degradation on the radial compression behaviour of wet spruce. Holzforschung 52(1):77–81

Vinden P, Torgovnikov GI, Hann J (2011) Microwave modification of radiata pine railway sleepers for preservative treatment. Eur J Wood Prod 69(2):271–279

Vongpradubchai S, Rattanadecho P (2009) The microwave processing of wood using a continuous microwave belt drier. Chem Eng Process 48(5):997–1003

Wangaard F (1950) The mechanical properties of wood. John Wiley, New York, p 377

Acknowledgements

This work was carried out at Research Center Josef Ressel in Brno-Útěchov and financially supported by the Internal Grant Agency (IGA) of the Faculty of Forestry and Wood Technology, Mendel University in Brno, (LDF_PSV_2016015). The authors gratefully acknowledge Thünen Institute of Wood Research for supporting the SEM analysis.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dömény, J., Čermák, P., Koiš, V. et al. Density profile and microstructural analysis of densified beech wood (Fagus sylvatica L.) plasticized by microwave treatment. Eur. J. Wood Prod. 76, 105–111 (2018). https://doi.org/10.1007/s00107-017-1173-z

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-017-1173-z