Abstract

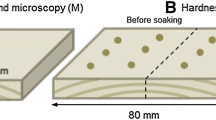

The mechanical properties of wood can be improved by compressing its porous structure between heated metal plates. By adjusting the process parameters it is possible to target the densification only in the surface region of wood where the property improvements are mostly needed in applications, such as flooring. The compressed form is, however, sensitive to moisture and will recover to some extent in high humidity. In this study, therefore, acetylated radiata pine was utilised in the surface densification process in order to both reduce the set-recovery of densified wood and to improve the hardness of the acetylated wood. Pre-acetylation was found to significantly reduce the set-recovery of surface densified wood. However, after the second cycle the increase in set-recovery of acetylated wood was relatively higher than the un-acetylated wood. The acetylated samples were compressed by only 1 mm (instead of the target 2 mm), yet, the hardness and hardness recovery of the acetylated samples significantly increased as a result of densification. It was also discovered that rough (un-planed) surfaces may be surface densified, however, even if the surface became smooth to the touch, the appearance remained uneven.

Similar content being viewed by others

References

Blomberg J, Persson B, Bexell U (2006) Effects of semi-isostatic densification on anatomy and cell-shape recovery on soaking. Holzforschung 60:322–331

Dinwoodie JM (2010) Timber: its nature and behavior. Taylor & Francis, New York, p 257

Dwianto W, Morooka T, Norimoto M, Kitajima T (1999) Stress relaxation of Sugi (Cryptomeria japonica D. Don) wood in radial compression under high temperature steam. Holzforschung 53:541–546

EN 1534 (2000) Wood and parquet flooring—determination of resistance to indentation (Brinell)—test method. CEN—European Committee for Standardization, Brussels

Fratzl P, Bugert I, Keckes J (2004) Mechanical model for the deformation of the wood cell wall. Z Metallkd 95(7):579–584

Heger F, Groux M, Girardet F, Welzbacher C, Rapp AO, Navi P (2004) Mechanical and durability performance of THM-densified wood. In: Proceedings of the final workshop COST action E22 ‘environmental optimization of wood protection’ Lisbon, Portugal, vol 22, pp 1–10

Inoue M, Norimoto M, Otsuka Y, Yamada T (1990) Surface compression of coniferous lumber I. A new technique to compress the surface layer. Mokuzai Gakkaishi 36:969–975

Jebrane M, Harper D, Labbé N, Sèbe G (2011) Comparative determination of the grafting distribution and viscoelastic properties of wood blocks acetylated by vinyl acetate or acetic anhydride. Carbohydr Polym 84:1314–1320

Keckes J, Burgert I, Frühmann K, Müller M, Kölln K, Hamilton M, Burghammer M, Roth SV, Stanzl-Tschegg S, Fratzl P (2003) Cell-wall recovery after irreversible deformation of wood. Nat Mater 2(12):810–813

Laine K, Rautkari L, Hughes M (2013) The effect of process parameters on the hardness of surface densified Scots pine solid wood. Eur J Wood Prod 71:13–16

Laine K, Segerholm K, Wålinder M, Rautkari L, Ormondroyd G, Hughes M, Jones D (2014) Micromorphological studies of surface densified wood. J Mat Sci 49:2027–2034

Lamason C, Gong M (2007) Optimization of pressing parameters for mechanically surface-densified aspen. For Prod J 57:64–68

Lankveld C, Alexander J, Tangen A, Olson T, Bongers F (2014) Accoya® wood flooring and decking in extreme environments. In: Proceedings of ECWM7—The 7th European conference on wood modification, Lisbon, Portugal

Larsson Brelid P, Simonson R, Risman PO (1999) Acetylation of solid wood using microwave heating. Part 1: studies of dielectric properties. Holz Roh Werkst 57:259–263

Larsson P, Simonson R (1994) A study of strength, hardness and deformation of acetylated Scandinavian softwoods. Holz Roh Werkst 52:83–86

Navi P, Heger F (2004) Combined densification and thermo-hydro-mechanical processing of wood. MRS Bull 29(5):332–336

Navi P, Pittet V, Plummer CJG (2002) Transient moisture effects on wood creep. Wood Sci Technol 36:447–462

Niemz P, Stübi T (2000) Investigations of hardness measurements on wood based materials using a new universal measurement system. In: Proceedings of the symposium on wood machining, properties of wood and wood composites related to wood machining, Vienna, Austria

Norimoto M, Ota C, Akitsu H, Yamada T (1993) Permanent fixation of bending deformation in wood by heat treatment. Wood Res 79:23–33

Obataya E, Furuta Y, Gril J (2003) Dynamic viscoelastic properties of wood acetylated with acetic anhydride solution of glucose pentaacetate. J Wood Sci 49:152–157

Papadopoulos AN, Tountziarakis P (2011) The effect of acetylation on the Janka hardness of pine wood. Eur Wood Prod 69:499–500

Pfriem A, Dietrich T, Buchelt B (2012) Furfuryl alcohol impregnation for improved plasticization and fixation during the densification of wood. Holzforschung 66:215–218

Popescu C-M, Hill CAS, Curling S, Ormondroyd G, Xie Y (2014) The water vapour sorption behaviour of acetylated birch wood: how acetylation affects the sorption isotherm and accessible hydroxyl content. J Mater Sci 49:2362–2371

Rautkari L, Laine K, Laflin N, Hughes M (2011) Surface modification of Scots pine: the effect of process parameters on the through thickness density profile. J Mat Sci 46(14):4780–4786

Rautkari L, Hänninen T, Johansson L-S, Hughes M (2012) A study by X-ray photoelectron spectroscopy (XPS) of the chemistry of the surface of Scots pine (Pinus sylvestris L.) modified by friction. Holzforschung 66:93–96

Rowell RM, Tillman AM, Simonson R (1986) A simplified procedure for the acetylation of hardwood and softwood flaxes for flakeboard production. J Wood Chem Technol 6(3):427–448

Rowell RM, Simonson R, Hess S, Plackett DV, Cronshaw D, Dunningham E (1994) Acetyl distribution in acetylated whole wood and reactivity of isolated wood cell-wall components to acetic anhydride. Wood Fiber Sci 26(1):11–18

Salmén L (1990) On the interaction between moisture and wood fibre materials. In: Materials interactions relevant to the pulp, paper and wood industries. MRS Proceedings Pittburgh, USA, vol 197, pp 193–201

Seltman J (1995) Opening the wood structure by UV-irradiation. Holz Roh Werkst 53:225–228

Tarkow H, Seborg R (1968) Surface densification of wood. For Prod J 18:104–107

Tarkow H, Stamm AJ, Erickson ECO (1955) Acetylated wood. Rep: 1593. Forest Products Laboratory, US Department of Agriculture Forest Service, Madison, WI, USA

Wålinder M, Omidvar A, Seltman J, Segerholm K (2009) Micromorphological studies of modified wood using a surface preparation technique based on ultraviolet laser ablation. Wood Mat Sci Eng 1–2:46–51

Wang JY, Cooper PA (2005) Effect of grain orientation and surface wetting on vertical density profile of thermally compressed fir and spruce. Holz Roh Werkst 63:397–402

Acknowledgments

The authors would like to acknowledge Accsys Technologies for providing the wood material for this study. The authors would also like to thank Joachim Seltman (SP, Sweden) and Joonas Kanerva (Aalto University) for technical support. The study was supported by the EcoBuild Centre, Stiftelsen Nils och Dorthi Troëdssons forskningsfond and the Finnish Cultural Foundation.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Laine, K., Segerholm, K., Wålinder, M. et al. Surface densification of acetylated wood. Eur. J. Wood Prod. 74, 829–835 (2016). https://doi.org/10.1007/s00107-016-1077-3

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-016-1077-3