Abstract

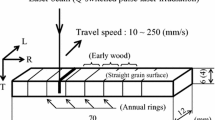

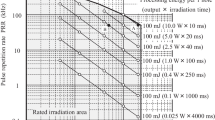

Wood was treated with lasers of 349- and 355-nm wavelength and 5- and 12-ns pulse width. First, holes were drilled in the wood, and high aspect ratio holes of 20-µm diameter and 5-mm depth were obtained within several seconds at 80 mW of output. The diameter of the holes was relatively uniform in the depth direction. Incising was then conducted on the wood surface at 667 holes/cm2, which resulted in no damage of the surface texture nor visually recognizable machining marks. Holes drilled with the laser were deepest when the focal point of the laser was set at the surface of the wood. Hole diameter on the surface was about 20 µm, and heat affected zone surrounding the holes was not recognized. With the aim of increasing the machining speed, the same process was conducted using a 5 W device as opposed to a 80 mW device, and machining time was reduced to 1/500th of the original time. The energy required to drill a hole of the same depth was also reduced to 1/10th of the original energy. In this test, changing the focusing lens to alter the optical focusing parameters changed the shape of the holes in the depth direction. When cutting of wood was attempted under these conditions at a speed of 50 mm/s, a cutting width of approximately 20 µm at a thickness of several millimeters was achieved.

Similar content being viewed by others

References

Arai T, Hayashi D (1992) Factors affecting the laser processing of wood. I. Effects of mechanical laser parameters on machinability. Mokuzai Gakkaishi 38(4):350–356

Barnekov VG, Mcmillin CW, Huber HA (1986) Factors influencing laser cutting of wood. Forest Prod J 36(1):55–58

Chong TC, Hong MH, Shi LP (2010) Laser precision engineering. From microfabrication to nanoprocessing. Laser Photon Rev 4(1):123–143

Fukuta S, Asada F, Sasaki Y (2008) The simultaneous treatment of compression drying and deformation fixation in the compression processing of wood. Forest Prod J 58(7/8):82–88

Goodell B, Kamke FA, Liu J (1991) Laser incising of spruce lumber for improved preservative penetration. Forest Prod J 41(9):48–52

Hattori N (1995) Laser processing of wood. Mokuzai Gakkaishi 41(8):703–709

Hattori N, Ando K, Kitayama S, Nakamura Y (1994) Laser incising of wood. Impregnation of columns with water-soluble dye. Mokuzai Gakkaishi 40(12):1381–1388

Hidai H, Itoh S, Tokura H, Nagasawa S, Tachikawa S (2010) High-aspect-ratio microdrilling with UV laser ablation. I. Drilling holes with an aspect-ratio of 190 in borosilicate glass. J Jpn Soc Precis Eng 76(10):1161–1165

Islam MN, Ando K, Yamauchi H, Kobayashi Y, Hattori N (2008) Comparative study between full cell and passive impregnation method of wood preservation for laser incised Douglas fir lumber. Wood Sci Technol 42:343–350

Laser Society of Japan (2006) Laser drilling. In: Laser processing application handbook, NGT, Tokyo, pp 153–163. Chap 4–2

Li L, Mazumder J (1991) A study of the mechanism of laser cutting of wood. Forest Prod J 41(10):53–59

Ruddick JNR (1991) Laser incising of Canadian softwood to improve treatability. Forest Prod J 41(4):53–57

Tokarev VN, Lopez J, Lazare S, Weisbuch F (2003) High-aspect-ratio microdrilling of polymers with UV laser ablation. Experiment with analytical model. Appl Phys A 76:385–396

Wang Y, Ando K, Hattori N (2013) Changes in the anatomy of surface and liquid uptake of wood after laser incising. Wood Sci Technol 47:447–455

Weck A, Crawford THR, Wilkinson DS, Haugen HK, Preston JS (2008) Laser drilling of high aspect ratio holes in copper with femtosecond, picosecond and nanosecond pulses. Appl Phys A 90:537–543

Acknowledgments

We extend our heartfelt thanks to the Advanced Machining Technology and Development Association for their assistance in carrying out this study.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fukuta, S., Nomura, M., Ikeda, T. et al. UV laser machining of wood. Eur. J. Wood Prod. 74, 261–267 (2016). https://doi.org/10.1007/s00107-016-1010-9

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-016-1010-9