Abstract

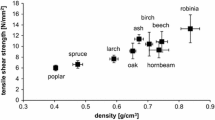

Delamination resistance and tensile shear strength (TSS) are essential for load-bearing timber structures. Thus these two factors were investigated on industrially bonded ash wood (Fraxinus excelsior L.) to check for the suitability of adhesively bonded ash wood as a building material. Two melamine urea formaldehyde (MUF) resins, two polyurethanes (PUR), one emulsion polymer isocyanate and one phenol resorcinol formaldehyde resin were taken for bonding. Face milled and planed surface series were made to highlight potential differences. For PUR, an additional series with dimethylformamide primed surfaces was also made. The influence of the mixing ratio and the closed assembly time were analysed for one MUF system. The samples for the TSS were tested in dry and wet conditions. 80 % of the tested series met the standard requirements (EN 15425; EN 301) in dry condition, whereas only 30% passed in wet condition. None of the adhesives tested were able to pass the delamination test. No distinct influence of the different parameters studied is notable for most of the adhesive systems, only extended CATs and lower MRs seem to improve the bond quality of MUF. In addition, chemical analyses were performed to find evidence for the poor bonding performance. It was found that acidic extractives, fatty acid content and pH of ash fell within the range of beech and spruce wood, with only formic acid being an exception with an amount four times higher than the other two wood species.

Similar content being viewed by others

References

Brändli U-B (2010) Swiss National Forest Inventory. Results of the third survey 2004–2006. Editor, Birmensdorf, Eidgenössische Forschungsanstalt für Wald, Schnee und Landschaft WSL. Bern, Bundesamt für Umwelt, BAFU. ISBN 9783905621471

DIN 53804-1 (2002) Statistical evaluation—Part 1: continuous characteristics. DIN Deutsches Institut für Normung e. V, Berlin

DIN 55957 (2000) Binders for paints and varnishes: methylation and silylation of fatty acids and analysis by gas chromatography. DIN Deutsches Institut für Normung e. V, Berlin

EN 15425 (2008) Adhesives—One component polyurethane for load bearing timber structures—Classification and performance requirements. European Committee for Standardization (CEN), Brussels

EN 301 (2013a) Adhesives, phenolic and aminoplastic, for load-bearing timber structures: classification and performance requirements. European Committee for Standardization (CEN), Brussels

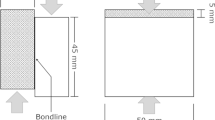

EN 302-1 (2013b) Adhesives for load-bearing timber structures—Test methods—Part 1: determination of longitudinal tensile shear strength. European Committee for Standardization (CEN), Brussels

EN 302-2 (2013c) Adhesives for load-bearing timber structures—Test methods—Part 2: Determination of resistance to delamination. European Committee for Standardization (CEN), Brussels

Gawron J, Antczak A, Borysiak S, Zawadzki J, Kupczyk A (2014) The study of glucose and xylose content by acid hydrolysis of ash wood (Fraxinus excelsior L.) after thermal modification in nitrogen by HPLC method. BioResources 9(2):3197–3210

Kläusler O, Hass P, Amen C, Schlegel S, Niemz P (2014) Improvement of tensile shear strength and wood failure percentage of 1C PUR bonded wooden joints at wet stage by means of DMF priming. Eur J Wood Prod 72(3):343–354

Knorz M, Schmidt M, Torno S, van de Kuilen JW (2014) Structural bonding of ash (Fraxinus excelsior L.): resistance to delamination and performance in shearing tests. Eur J Wood Prod 72(3):297–309

Knorz M, Neuhaeuser E, Torno S, van de Kuilen J-W (2015) Influence of surface preparation methods on moisture-related performance of structural hardwood–adhesive bonds. Int J Adhes Adhes 57:40–48

Krackler V, Keunecke D, Hurst A, Niemz P (2011) Possible fields of hardwood application. Wood Res 56(1):125–136

Lai Y-Z, Guo X-P (1991) Variation of the phenolic hydroxyl group content in wood lignins. Wood Sci Technol 25(6):467–472

López-Suevos F, Richter K (2009) Hydroxymethylated resorcinol (HMR) and Novolak-based HMR (n-HMR) primers to enhance bond durability of eucalyptus globulus glulams. J Adhes Sci Technol 23(15):1925–1937

Luedtke J, Amen C, van Ofen A, Lehringer C (2015) 1C-PUR-bonded hardwoods for engineered wood products: influence of selected processing parameters. Eur J Wood Prod 73(2):167–178

Mansouri NE, Yuan Q, Huang F (2011) Characterization of alkaline lignins for use in phenol-formaldehyde and epoxy resins. BioResources 6(3):2647–2662

Ohnesorge D, Richter K, Becker G (2010) Influence of wood properties and bonding parameters on bond durability of European Beech (Fagus sylvatica L) glulams. Ann For Sci 67(6):601–610

Schmidt M, Glos P, Wegener G (2010) Gluing of European beech wood for load bearing timber structures. Eur J Wood Prod 68:43–57 (in German)

Ucar M, Ucar G (2008) Variations of wood acidity in hard-and softwoods during storage up to one year. Wood Research 53(4):105–114

Vick C, Richter K, River B, Fried A (1995) Hydroxymethylated resorcinol coupling agent for enhanced durability of bisphenol-A epoxy bonds to sitka spruce. Wood Fiber Sci 27(1):2–12

Acknowledgments

This research was carried out at ETH Zurich and funded through the National Research Programme NRP 66 of the Swiss National Science Foundation and the forest and timber research fund of the Swiss Federal Office for the Environment FOEN.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ammann, S., Schlegel, S., Beyer, M. et al. Quality assessment of glued ash wood for construction engineering. Eur. J. Wood Prod. 74, 67–74 (2016). https://doi.org/10.1007/s00107-015-0981-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-015-0981-2