Abstract

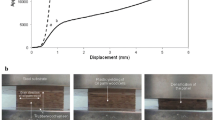

Sandwich panels with expanded cork agglomerates as core and Aleppo pine wood veneer as face sheets were developed and characterized for compression (in plane and out of plane), traction and bending (three and four point). The load–displacement curves and fracture patterns were analyzed. The expanded cork agglomerate core allowed very good performance under compression while the wood layers strengthened the panel in relation to tensile stresses. Increasing the number of layers had a positive impact on the mechanical performance of the sandwich structure. Such eco-friendly, light and low cost sandwich panels can be used as non-structural construction elements such as partition walls.

Similar content being viewed by others

References

Alcantara F, Teixeira D, Paulino M (2013) Cork composites for the absorption of impact energy. Compos Struct 95:16–27

Amen-Chen C, Pakdel H, Roy C (2001) Production of monomeric phenols by thermochemical conversion of biomass: a review. Bioresour Technol 79:277–299

Anjos O, Pereira H, Rosa ME (2008) Effect of quality; porosity and density on the compression properties of cork. Holz Roh Werkst 66(4):295–301

Anjos O, RodriguesC Morais J, Pereira H (2014) Effect of density on the compression behaviour of cork. Mater Design 53:1089–1096

Baptista APM, Vaz MDC (1993) Comparative wear testing of flooring materials. Wear 162:990–995

Castro O, Silva JM, Devezas T, Silva A, Gil L (2010) Cork agglomerates as an ideal core material in lightweight structures. Mater Design 31:425–432

Diaz A, Diaz MA, Macias A, Rosa P, Serrano V (2003) Bending strength of black and composite agglomerates of cork. Mater Lett 57:4004–4008

Fernandes R, Moura MFSF, Silva FGA, Dourado N (2014) Mode I fracture characterization of a hybrid cork and carbon–epoxy laminate. Compos Struct 112:248–253

Ferreira E, Pereira H (1986) Some anatomical and chemical changes in manufacturing cork black agglomerates. Cortiça 576:274–279

Fortes MA, Rosa ME, Pereira H (2004) A cortiça, IST Press, Lisboa

Gibson LJ, Ashby MF (1997) Cellular solids: structure and properties, 2nd edn. University Press, Cambridge

Gibson LJ, Easterling KE, Ashby MF (1981) The structure and mechanics of cork. In: Proceedings of the Royal Society London series A-Math Phys Eng Sci 377:99-117

Gil L (2007) Cork as a building material. Technical manual, APCOR, Portugal

Gil L (2009) Cork composites: a review. Materials 2(3):776–789

Moreira RAS, Melo FJQ, Dias Rodrigues JF (2010) Static and dynamic characterization of composition cork for sandwich beam cores. J Mater Sci 45(12):3350–3366

NFT 54-602 (1983) Plastics based sandwich structures-perpendicular compression test, Afnor 83647

NFT 54-603 (1983) Plastics based sandwich structures-perpendicular tensile test, Afnor 83648

NFT 54-604 (1986) Plastics based sandwich structures–longitudinal compression test without or with buckling, Afnor 86618

NFT 54-606 (1987) Plastics based sandwich structures-bend test, Afnor 87461

Pereira H (1992) The thermochemical degradation of cork. Wood Sci Technol 26:259–269

Pereira H (2007) Cork: biology, production and uses. Elsevier, Amsterdam

Pereira H, Baptista C (1993) Influence of raw material quality and process parameters in the production of insulation cork agglomerates. Holz Roh Werkst 51(5):301–308

Pereira H, Ferreira E (1989) Scanning electron microscopy observation of insulation cork agglomerates. Mater Sci Eng A111:217–225

Pinto A, Melo B (1988) Insulation: black agglomerated cork and other insulating materials. Cortiça 602:322–328

Reis L, Silva A (2009) Mechanical behaviour of sandwich structures using natural cork agglomerates as core materials. J Sandw Struct Mater 11:487–500

Rosa ME, Fortes MA (1988a) Temperature induced alterations of the structure and mechanical properties of cork. Mater Sci Eng 100:69–78

Rosa ME, Fortes MA (1988b) Rate effects on the compression and recovery of dimensions of cork. J Mater Sci 23(3):879–885

Rosa ME, Pereira H (1994) The effect of long term treatment at 100°C–150°C on structure, chemical composition and compression behavior of cork. Holzforschung 48:226–232

Sen A, Velez Marques A, Gominho J, Pereira H (2012) Study of thermochemical treatments of cork in the 150 400 & #xB0;C range using colour analysis and FTIR spectroscopy. Ind Crop Prod 38:132–138

Sen A, Van den Bulcke J, Defoirdt N, Jo Van Acker, Pereira H (2014) Thermal behaviour of cork and cork components. Thermochim Acta 582:94–100

Shivakumar Kl, Chen H (2009) Structural performance of eco-core sandwich panels. In: Daniel IM, Gdoutos EE, Rajapakse YDS (eds) Major Accomplishments in Composite Materials and Sandwich Structures, Springer Netherlands, pp 381–405

Silva SP, Sabino MA, Fernandes EM, Correlo VM, Boesel LF, Reis RL (2005) Cork: properties, capabilities and applications. Int Mater Rev 50(6):345–365

Simoes N, Moreira A, Branco FG (2007) Effect of natural and expanded granulated cork on strength and thermal behaviour of concrete. In: 35th IAHS World Congress on Housing-planning design construction performance. Melbourne, Australia, pp 4–7

Sousa-Martins J, Kakogiannis D, Coghe F, Reymen B, Teixeira-Dias F (2013) Behaviour of sandwich structures with cork compound cores subjected to blast wave. Eng Struct 46:140–146

Vaz MF, Fortes MA (1998) Friction properties of cork. J Mater Sci 33:2087–2093

Vinson JR (1999) The behaviour of sandwich structures of isotropic and composite materials. Technomic Publishing Co, Lancaster

Zenkert D (1997) The handbook of sandwich construction. EMAS Publishing, London

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lakreb, N., Bezzazi, B. & Pereira, H. Mechanical strength properties of innovative sandwich panels with expanded cork agglomerates. Eur. J. Wood Prod. 73, 465–473 (2015). https://doi.org/10.1007/s00107-015-0908-y

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-015-0908-y