Abstract

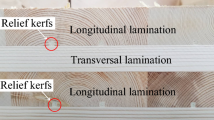

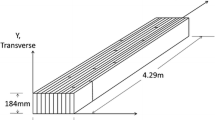

This paper presents the results of a study in which novel engineered composite lumber was developed, manufactured and tested. The engineered composite lumber was made by edge-laminating lower-grade No. 3 solid-sawn southern pine (SP) lumber with higher-grade tension chord material to yield tension chord lumber (TCL). Three groups of TCL (38 mm × 235 mm × 4.9 m) were made with varying combinations of SP lumber including machine stress rated (MSR) 2400Fb-2.0E, MSR 2400Fb-2.0E finger joint, and visually graded No. 1 finger joint material. One group of visually graded No. 3 control lumber (38 mm × 184 mm × 4.9 m) was also tested. All specimens were tested in static four-point bending on a universal testing machine. The modulus of elasticity (MOE) and modulus of rupture (MOR) were determined. The TCL lumber had significantly greater MOE values as compared with the control lumber. The mean MOE values of TCL ranged from 12.4 to 12.6 GPa, as compared with 9.6 GPa for the control group. The mean MOR values of TCL ranged from 39.3 to 47.6 MPa, as compared with 35.9 MPa for the control group. Perhaps most importantly, the 5th percentile values of MOR of the TCL were approximately double those of the control group, 29.1, 27.0, and 27.4 MPa versus 11.8 MPa, respectively.

Similar content being viewed by others

References

ASTM Standard D198-08 (2009) Standard Methods of static tests of timbers in structural sizes. American Society for Testing and Materials, Philadelphia

Buchanan AH (1990) Bending strength of lumber. J Struct Eng 116:1213–1229

Bulleit WM (1983) Reinforcement of wood materials: a review. Wood Fiber Sci 16(3):391

Clouston P, Schreyer A (2006) Wood concrete composites: A structurally efficient material option. Civil Engineering Practice. Boston Society of Civil Engineers (BSCE) Section/American Society of Civil Engineers (ASCE), 5-22

Clouston P, Bathon LA, Schreyer A (2005) Shear and bending performance of a novel wood–concrete composite system. J Struct Eng 131(9):1404

Dahlen J, Jones PD, Seale RD, Shmulsky R (2012) Bending strength and stiffness of in-grade Douglas-fir and southern pine No.2 2 × 4 lumber. Can J For Resour 42:858–867

Dahlen J, Jones PD, Seale RD, Shmulsky R (2013) Stiffness and strength of on-grade southern pine No. 2 wide dimension lumber. Forest Products Society 67th International Convention. Austin, TX. June 9–11

Fiorelli J, Dias AA (2003) Analysis of the strength and stiffness of timber beams reinforced with carbon fiber and glass fiber. Mater Res 6:193–202

Johns KC, Lacroix S (2000) Composite reinforcement of timber in bending. Can J Civ Eng 27:899–906

Kakeh M, Dahlen J, Shmulsky R, Jones PD, Seale RD (2012) Bowtie Beams: novel Engineered Structural Beams from Southern Pine Lumber. Wood Fiber Sci 44(3):1–9

Nolan R (2010) Determining allowable design values for wood. American Forest and Paper Association and American Wood Council

Raftery GM, Harte AM (2011) Low-grade glued laminated timber reinforced with FRP plate. Compos B Eng 42(4):724–735

SFPA (2013) Southern pine use guide. Southern Forest Products Association

US Census Bureau (2012) Lumber production and mill stocks: 2010. http://www.census.gov/manufacturing/cir/historical_data/ma321t/ma321t10.xls. Accessed June 27, 2012

Acknowledgments

The author wish to acknowledge the support of U.S. Department of Agriculture (USDA), Research, Education, and Economics (REE), Agriculture Research Service (ARS), Administrative and Financial Management (AFM), Financial Management and Accounting Division (FMAD) Grants and Agreements Management Branch (GAMB), under Agreement No. 5B-0202-4-00. Any opinions, findings, conclusion, or recommendations expressed in this publication are those of the author(s) and do not necessarily reflect the view of the U.S. Department of Agriculture. Gratitude is also expressed to Momentive Speciality Chemicals Inc. for their donation of resin.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, B.Z., Seale, R.D., Dahlen, J. et al. Bending properties of a novel engineered composite from southern pine lumber. Eur. J. Wood Prod. 72, 601–607 (2014). https://doi.org/10.1007/s00107-014-0821-9

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-014-0821-9