Abstract

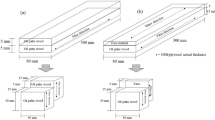

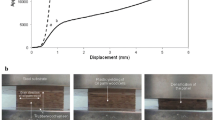

Low-density sandwich panels consisting of an oil palm wood core overlaid with a rubberwood veneer face were manufactured. Effects of two types of grain orientation of the oil palm wood core (parallel and perpendicular to board surface) and three different veneer thicknesses (0.7, 1.8 and 2.7 mm) and core densities (223 ± 14, 301 ± 35 and 418 ± 33 kg/m3) on some physical and mechanical properties of the boards were investigated. Results showed that higher core density increased the values of thermal conductivity, screw withdrawal resistance, modulus of rupture and modulus of elasticity but decreased the value of water absorption without effect on thickness swelling of the boards. Boards with the core grain direction oriented perpendicular to panel’s surface possessed lower value of thickness swelling but higher values of thermal conductivity and strain at fracture when the board failed in a mode of core shear under bending test than those of the others. Finally, the relationship between board density and the measured physical and mechanical properties of the oil palm wood core sandwich panels overlaid with a rubberwood veneer expressed as mathematical equations could be used to predict and design the expected properties of this type of sandwich board.

Similar content being viewed by others

References

Abdul Khalil HPS, Siti Alwani M, Ridzuan R, Kamarudin S, Khairul A (2008) Chemical composition, morphological characteristics, and cell wall structure of malaysian oil palm fibers. Polym Plast Technol Eng 47(3):273–280

Abdul Khalil HPS, Nurul Fazita MR, Bhat AH, Jawaid M, Nik Fuad NA (2010) Development and material properties of new hybrid plywood from oil palm biomass. Mater Des 31:417–424

Alavez-Ramirez R, Chiñas-Castillo F, Morales-Dominguez VJ, Ortiz-Guzmana M (2012) Thermal conductivity of coconut fibre filled ferrocement sandwich panels. Constr Build Mater 37:425–431

Allen HG (1969) Analysis and design of structural sandwich panels. Pergamon press, London

Ashby MF (1992) Materials selection in mechanical design. Pergamon Press, Oxford

Ashby FM, Evans AG, Fleck NA, Gibson LJ, Hutchinson JW, Wadley HGN (2000) Metal foams: a design guide. Butterworth-Heinemann, Boston

ASTM D1037-12 (2012) Standard test methods for evaluating properties of wood-based fiber and particle panel materials. ASTM Annual Book of Standards. ASTM International, West Conshohocken

ASTM C177-10 (2010) Standard test method for steady-state heat flux measurements and thermal transmission properties by means of the guarded-hot-plate apparatus. Annual Book of Standards. American Society for Testing and Materials, ASTM International, West Conshohocken

Aytekin A (2008) Determination of screw and nail withdrawal resistance of some important wood species. Int J Mol Sci 9:626–637

Barala N, Cartiéb DDR, Partridgeb IK, Baleyc C, Daviesd P (2010) Improved impact performance of marine sandwich panels using through thickness reinforcement: experimental results. Compos B Eng 41(2):117–123

Biblis EJ, Lee WC (1984) Properties of sheathing-grade plywood made from sweetgum and southern pine. Wood Fiber Sci 16(1):86–92

Borjesson P, Gustavsson L (2000) Greenhouse gas balances in building construction: wood versus concrete from life-cycle and forest land-use perspectives. Energy Policy 28(9):575–588

Büyüksari Ü, Hiziroglu S, Akkiliç H, Ayrılmış N (2012) Mechanical and physical properties of medium density fibreboard panels laminated with thermally compressed veneer. Composites (Part B) 43:110–114

Cai Z, Ross RJ (2010) Mechanical properties of wood based composite materials. In: Ross RJ (ed) Wood handbook—wood as an engineering material, General Technical Report, FPL-GTR-190. USDA Forest Service, Forest Products Laboratory, Madison, Wisconsin, pp 12-1–12-12

Crump DA, Dulieu-Barton JM (2010) Performance assessment of aerospace sandwich secondary structure panels using thermoelastic stress analysis. Plast Rubber Compos 39(3–5):137–147

EN 300 (1997) Oriented strand boards (OSB)—definitions, classification and specifications. European Committee for Standardization (CEN), Brussels

EN 310 (1993) Particleboards and fibreboards—determination of modulus of elasticity in bending and of bending strength. European Committee for Standardization (CEN), Brussels

EN 317 (1993) Particleboards and fibreboards—determination of swelling in thickness after immersion in water. European Committee for Standardization (CEN), Brussels

EN 320 (2011) Particleboards and fibreboards—determination of resistance to axial withdrawal of screws. European Committee for Standardization (CEN), Brussels

EN 323 (1993) Wood-based panels—determination of density. European Committee for Standardization (CEN), Brussels

EN 622-3 (2004) Fibreboards specifications– Requirements for medium boards. European Committee for Standardization (CEN), Brussels

Glass SV, Zelinka SL (2010) Moisture relations and physical properties of wood. In: Wood handbook—wood as an engineering material, General Technical Report, FPL-GTR-190. USDA Forest Service, Forest Products Laboratory, Madison, Wisconsin, pp 4-1–4-19

Haslett AN (1990) Suitability of oil palm trunk for timber uses. J Trop For Sci 2(3):243–251

Hibberler RC (1997) Mechanics of materials, 3rd edn. Prentice-Hall, New Jersey

Hoo F, Michelle S, Sirivolu D (2010) A wave propagation model for the high velocity impact response of a composite sandwich panel. Int J Impact Eng 37:117–130

JIS A 5905 (1994) Fibreboards. Japanese Industrial Standard, Tokyo

Kawasaki T, Kawai S (2006) Thermal insulation properties of wood-based sandwich panel for use as structural insulated walls and floors. Jpn Wood Res Soc 52:75–83

Kwon JH, Ayrilmis N, Han TH (2012) Enhancement of flexural properties and dimensional stability of rice husk particleboard using wood strands in face layers. Composites (Part B) 44:728–732

Lide DR (1998) CRC handbook of chemistry and physics, 79th edn. CRC Press, Boca Raton

Lim SC, Gan KS (2005) Timber Technology Bulletin, Forest Research Institute Malaysia: Selangor, Malaysia, pp 1-11

Lim SC, Khoo KC (1986) Characteristics of oil palm trunk and its potential utilisation. Malays For 49(1):3–21

Mousa MA, Uddin N (2011) Flexural behavior of full-scale composite structural insulated floor panels. Adv Compos Mater 20:547–567

Mullens M, Arif M (2006) Structural insulated panels: impact on the residential construction process. J Constr Eng Manage 132(7):786–794

Panjehpour M, Abang Ali AA, Voo YL (2013) Structural insulated panels: past, present, and future. J Eng Proj Prod Manag 3(1):2–8

Shinoj S, Visvanathanb R, Panigrahic S, Kochubabu M (2011) Oil palm fiber (OPF) and its composites: a review. Ind Crops Prod 33(1):7–22

Skaar C (1972) Water in Wood. Syracuse University Press, Syracuse

Srivaro S, Chaowana P, Matan N, Kyokong B (2014) Lightweight sandwich panel from oil palm wood core and rubberwood veneer face. J Trop For Sci 26(1):50–57

Suhaily SS, Jawaid M, Abdul Khalil HPS, Mohamed AR, Ibrahim F (2012) A review of oil palm biocomposites for furniture design and applications: potential and challenges. Bioresource 7(3):4400–4423

Sulaiman O, Salim N, Nordin NA, Hashim R, Ibrahim M, Sato M (2012) The potential of oil palm trunk biomass as an alternative source for compressed wood. Bioresource 7(2):2688–2706

Taj MA, Najafi SK, Ebrahimi G (2009) Withdrawal and lateral resistance of wood screw in beech, hornbeam and poplar. Eur J Wood Prod 67:135–140

Terentiuk S, Memari A (2012) In-plane monotonic and cyclic racking load testing of structural insulated panels. J Archit Eng 18(4):261–275

Tracy J (2000) SIPs: overcoming the elements. For Prod J 50(3):12–18

Vaidya A, Uddin U, Vaidya U (2010) Structural characterization of composite structural insulated panels for exterior wall applications. J Compos Constr 14(4):464–469

Youngquist JA (1999) Wood-based composites and panel products. In: Wood handbook—wood as an engineering material, General Technical Report, FPL-GTR-113. USDA Forest Service, Forest Products Laboratory, Madison, Wisconsin

Zenkert D (1997) An introduction to sandwich construction. EMAS, London

Acknowledgments

The authors gratefully acknowledge the Thailand Research Fund through the Royal Golden Jubilee Ph.D. Program (Grant No.PHD/0065/2552) for the financial support, Phang-Nga Timber Industries Co., Ltd., Phang-Nga, Thailand for providing the raw materials and facilities for the experimental work and Dynea Krabi Co., Ltd., Songkhla, Thailand for providing MUF adhesives used in this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Srivaro, S., Matan, N., Chaowana, P. et al. Investigation of physical and mechanical properties of oil palm wood core sandwich panels overlaid with a rubberwood veneer face. Eur. J. Wood Prod. 72, 571–581 (2014). https://doi.org/10.1007/s00107-014-0817-5

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-014-0817-5