Abstract

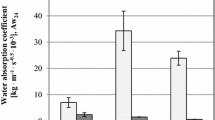

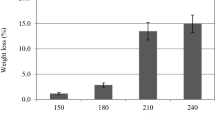

Sapwood and heartwood samples of Pinus pinaster were treated in an oven at 190 and 200 °C for 2–6 h. Dimensional stability, measured as Anti Shrinking Efficiency (ASE) between 0 and 65 % relative humidity, durability against fungi, mechanical resistance (MOE and MOR), hardness and chemical composition were determined for treated and untreated sapwood and heartwood. Radial ASE reached 52 % for sapwood and 50 % for heartwood, while tangential ASE reached 50 and 40 %, respectively. MOE increased slightly at the beginning of the treatment, decreasing afterwards. No significant differences were found between sapwood and heartwood. MOR decreased by 50 and 30 % for sapwood and heartwood, respectively. A significant increase in durability against Rhodonia placenta was found for both heartwood and sapwood at the higher temperature (200 °C), but at the lower temperature (190 °C) only heartwood showed good results.

Zusammenfassung

Pinus pinaster Splint- und Kernholzprüfkörper wurden in einem Ofen bei 190 und 200 °C für eine Dauer von 2–6 Stunden behandelt. Es wurde die Dimensionsstabilität als Schwindungsvergütung (ASE) zwischen 0 und 65 % rel. Luftfeuchte sowie die Dauerhaftigkeit gegen holzzerstörende Pilze, die mechanischen Eigenschaften (Elastizitätsmodul (MOE) und Biegefestigkeit (MOR)), die Härte und die chemische Zusammensetzung von behandeltem und unbehandeltem Splint- und Kernholz bestimmt. Die radiale Schwindungsvergütung von Splintholz betrug 52 % und von Kernholz 50 %; die tangentiale Schwindungsvergütung von Splintholz betrug 50 % und von Kernholz 40 %. Der Elastizitätsmodul nahm zu Behandlungsbeginn leicht zu und nahm anschließend ab. Bei Splint- und Kernholz zeigten sich keine signifikanten Unterschiede. Die Biegefestigkeit von Splintholz nahm um 50 % ab, die von Kernholz um 30 %. Sowohl Splint- als auch Kernholz wiesen bei der höheren Temperatur (200 °C) eine erhöhte Dauerhaftigkeit gegen den holzzerstörenden Pilz Rhodonia placenta auf, wogegen bei der niedrigeren Temperatur (190 °C) nur Kernholz gute Ergebnisse zeigte.

Similar content being viewed by others

References

Boonstra M (2008)A two-stage thermal modification of wood, Ph.D. thesis in applied biological sciences: soil and forest management. Henry Poincaré University-Nancy, France

Boonstra M, Tjeerdsma B, Groeneveld H (1998) Thermal modification of non-durable wood species 1. The Plato technology: thermal modification of wood, International Research Group Wood Pro, section 4: processes. 29 Annual meeting, Maastricht, June 14–19, p 13

Boonstra M, Van Acker J, Kegel E, Stevens M (2007) Optimisation of a two-stage heat treatment process. Durability aspects. Wood Sci Technol 41(1):31–57

CEN/TS 15083-1 (2005) Durability of wood and wood-based products. Determination of the natural durability of solid wood against wood-destroying fungi, test methods. Part 1: basidiomycetes. CEN, Brussels

Dirol D, Guyonnet R (1993) Durability by rectification process, In: International Research Group Wood Pro, section 4: processes, Nº IRG/WP 93-40015

Esteves BM, Pereira H (2009) Wood modification by heat treatment: a review. BioResources 4(1):340–404

Esteves B, Marques AV, Domingos I, Pereira H (2006) Influence of steam heating on the properties of pine (Pinus pinaster) and eucalypt (Eucalyptus globulus) wood. Wood Sci Technol 41:193–207

Esteves B, Domingos I, Pereira H (2007a) Improvement of technological quality of eucalypt wood by heat treatment in air at 170–200 degrees. C For Prod J 57(1–2):47–52

Esteves B, Velez Marques A, Domingos I, Pereira H (2007b) Heat-induced colour changes of pine (Pinus pinaster) and eucalypt (Eucalyptus globulus) wood. Wood Sci Technol 42(5):369–384

Esteves B, Graça J, Pereira H (2008a) Extractive composition and summative chemical analysis of thermally treated eucalypt wood. Holzforschung 62(3):344–351

Esteves BM, Domingos IJ, Pereira H (2008b) Pine wood modification by heat treatment in air. BioResources 3(1):142–154

Esteves B, Videira R, Pereira H (2011) Chemistry and ecotoxicity of heat-treated pine wood extractives. Wood Sci Technol 45(4):661–676

Hakkou M, Pétrissans M, El Bakali I, Gérardin P, Zoulalian A (2005) Wettability changes and mass loss during heat treatment of wood. Holzforschung 59(1):35–37

Hakkou M, Pétrissans M, Gérardin P, Zoulalian A (2006) Investigations of the reasons for fungal durability of heat-treated beech wood. Polymer Degrad Stab 91(2):393–397

ISO 3350-Wood (1975) Determination of static hardness

Kamdem D, Pizzi A, Jermannaud A (2002) Durability of heat-treated wood. Holz Roh-Werkst 60:1–6

Kim G, Yun K, Kim J (1998) Effect of heat treatment on the decay resistance and the bending properties of radiata pine sapwood. Mater Org 32(2):101–108

Kocaefe D, Poncsak S, Dore G, Younsi R (2008) Effect of heat treatment on the wettability of white ash and soft maple by water. Holz Roh-Werkst 66:355–361

Korkut S, Hiziroglu S (2009) Effect of heat treatment on mechanical properties of hazelnut wood (Corylus colurna). Mater Des 30(5):1853–1858

Korkut S, Akgü M, Dündar T (2008) The effects of heat treatment on some technological properties of Scots pine (Pinus sylvestris L.) wood. Bioresour Technol 99:1861–1868

Metsä-Kortelainen S (2011) Differences between sapwood and heartwood of thermally modified Norway spruce (Picea abies) and Scots pine (Pinus sylvestris) under water and decay exposure, VTT, Espoo. VTT Publications, p 771

Metsä-Kortelainen S, Viitanen H (2009) Decay resistance of sapwood and heartwood of untreated and thermally modified Scots pine and Norway spruce compared with some other wood species. Wood Mat Sci Eng 4(3–4):105–114

Metsä-Kortelainen S, Viitanen H (2012) Wettability of sapwood and heartwood of thermally modified Norway spruce and Scots pine. Eur J WoodProds 70:135–139

Metsä-Kortelainen S, Antikainen T, Viitaniemi P (2006) The water absorption of sapwood and heartwood of Scots pine and Norway spruce heat-treated at 170, 190, 210 and 230 °C. Holz Roh-Werkst 64(3):192–197

Mitsui K, Takada H, Sugiyama M, Hasegawa R (2001) Changes in the properties of light-irradiated wood with heat treatment: part 1 effect of treatment conditions on the change in color. Holzforschung 55:601–605

NP 619 (1973) Ensaio de flexão estática de madeiras (Static bending test for wood)

Pecina H, Paprzycki O (1988) Wechselbeziehungen zwischen der Temperaturbehandlung des Holzes und seiner Benetzbarkeit. Holz Holzverwert 40(1):5–8

Pétrissans M, Philippe G, El Bakali I, Serraj M (2003) Wettability of heat-treated wood. Holzforschung 57:301–307

Poncsák S, Kocaefe D, Bouazara M, Pichette A (2006) Effect of high temperature treatment on the mechanical properties of birch (Betula papyrifera). Wood Sci Technol 40(8):647–663

Sailer M, Rapp A, Leithoff H (2000) Improved resistance of Scots pine and spruce by application of an oil-heat treatment, In: International Research Group Wood Pre, section 4-processes, Nº IRG/WP 00-40162

Stamm AJ, Burr HK, Kline AA (1946) Staybwood: heat-stabilized wood. Ind Eng Chem 38(6):630–634

Sundqvist B, Karlsson O, Westermark U (2006) Determination of formic-acid and acetic acid concentrations formed during hydrothermal treatment of birch wood and its relation to colour, strength and hardness. Wood Sci Technol 40(7):549–561

Tappi T 264 cm-97 (1997) Peparation of wood for chemical analysis. Technical Association of the Pulp and Paper Industry/07-Apr-1997

Tappi 204 Mac-88 (1988) Solvent extractives of wood and pulp. Technical Association of the Pulp and Paper Industry

Tjeerdsma B, Stevens M, Militz H, Van Acker J (2002) Effect of process conditions on moisture content and decay resistance of hydro-thermally treated wood. Holz Holzverwert 5:94–99

Viitaniemi P, Jämsä S, Viitanen H (1997) Method for improving biodegradation resistance and dimensional stability of cellulosic products, United States patent Nº 5678324 (US005678324)

Acknowledgments

The authors are grateful for the support of the Portuguese Foundation for Science and Technology (FCT) and Center for Studies in Education, Technologies and Health essential for the accomplishment of this work. The Forest Research Centre is funded by FCT.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Esteves, B., Nunes, L., Domingos, I. et al. Comparison between heat treated sapwood and heartwood from Pinus pinaster . Eur. J. Wood Prod. 72, 53–60 (2014). https://doi.org/10.1007/s00107-013-0751-y

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-013-0751-y