Abstract

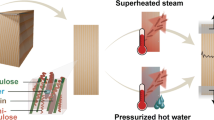

Scots pine sapwood and heartwood were thermally modified under saturated steam at 120, 150 and 180 °C in a high pressure reactor. Mechanical properties such as dynamic and static modulus of elasticity (MOE), static modulus of rupture (MOR), Brinell hardness and impact toughness were evaluated. The static MOE for sapwood did not decrease substantially (approximately 1 %), not even with a high mass loss of more than 12 %, when the wood was modified at 180 °C. Static MOE of the wood increased approximately 14 %, when modified at 150 °C. Surprisingly, MOR increased by 15 %, when modified at 150 °C with mass loss of 2.3 %. Whereas impact strength and hardness decreased somewhat, when modified at 180 °C. Moreover, high anti-swelling efficiency values were obtained (60 % for sapwood and 52 % for heartwood) when modified at 180 °C.

Zusammenfassung

Kiefernsplintholz und –kernholz wurde in einem Hochdruckreaktor unter Sattdampfbedingungen bei Temperaturen von 120, 150 und 180 °C thermisch modifiziert. Die mechanischen Eigenschaften dynamischer und statischer Elastizitätsmodul (MOE), statische Biegefestigkeit (MOR), Brinell Härte und Schlagzähigkeit wurden bestimmt. Der statische Elastizitätsmodul von Splintholz nahm auch bei einem hohen Masseverlust von über 12 %, wenn das Holz bei einer Temperatur von 180 °C modifiziert wurde, nicht wesentlich ab (ca. 1 %). Der statische Elastizitätsmodul nahm bei einer Modifizierung bei 140 °C um ca. 14 % zu. Überraschenderweise stieg die Biegefestigkeit bei einer thermischen Modifikation bei 150 °C und einem Masseverlust von 2,3 % um 15 % an. Die Schlagzähigkeit und die Brinell Härte nahmen bei einer thermischen Modifikation bei 180 °C ein wenig ab. Dagegen wurde bei dieser Temperatur ein hohes Quellresistenzvermögen erzielt (Splintholz 60 % und Kernholz 52 %).

Similar content being viewed by others

References

Bhuiyan MTR, Hirai N, Sobue N (2000) Changes of crystallinity in wood cellulose by heat treatment under dried and moist conditions. J Wood Sci 46:431–436

Boonstra MJ, Van Acher J, Tjeerdsma BF, Kegel EV (2007) Strength properties of thermally modified softwoods and its relation to polymeric structural wood constituents. Ann For Sci 64:679–690

Borrega M, Kärenlampi PP (2008) Effect of relative humidity on thermal degradation of Norway spruce (Picea abies) wood. J Wood Sci 54:323–328

Borrega M, Kärenlampi PP (2010) Hygroscopicity of heat-treated Norway spruce (Picea abies) wood. Eur J Wood Prod 68:233–235

Dagbro O, Torniainen P, Karlsson O, Morén T (2010) Colour responses from wood, thermally modified in superheated steam and pressurized steam atmospheres. Wood Mat Sci Eng 5:211–219

Ding T, Lianbai G, Liu X (2011) Influence of steam pressure on chemical changes of heat-treated Mongolian pine wood. Bioresources 6:1880–1889

Dwianto W, Takana F, Inoue M, Norimoto M (1996) Crystallinity changes of wood by heat or steam treatment. Wood Res 83:47–49

EN 1534 (2000) Wood and parquet flooring—determination of resistance to indentation (Brinell)—Test method. CEN—European Committee for Standardization, Brussels

EN 408 (2011) Timber structures. Structural timber and glued laminated timber. Determination of some physical and mechanical properties. CEN—European Committee for Standardization, Brussels

EN ISO 179-1 (2010) Plastics. Determination of Charpy impact properties. Part 1: non-instrumented impact test. CEN—European Committee for Standardization, Brussels

Haines DW, Leban JM, Herbé C (1996) Determination of Young’s modulus for spruce, fir and isotropic materials by resonance flexure method with comparisons to static flexure and other dynamic methods. Wood Sci Technol 30:253–263

Hill CAS (2006) Wood modification—chemical, thermal and other processes. John Wiley and Sons Ltd., Chichester

Hill CAS, Ramsay J, Keating B, Laine K, Rautkari L, Hughes M, Constant B (2012) The water vapour sorption properties thermally modified and densified wood. J Mat Sci 47:3191–3197

Korkut S, Budakçı M (2009) Effect of high-temperature treatment on the mechanical properties of Rowan (Sorbus aucuparia L.) wood. Drying Technol 27:1240–1247

Korkut S, Akgül M, Dünbar T (2008) The effects of heat treatment on some technological properties of Scots pine (Pinus sylvestris L.) wood. Bioresour Technol 99:1861–1868

Metsä-Kortelainen S, Viitanen H (2010) Effect of fungal exposure on the strength of thermally modified Norway spruce and Scots pine. Wood Mat Sci Eng 1(13):23

Metsä-Kortelainen S, Antikainen T, Viitaniemi P (2006) The water absorption of sapwood and heartwood of Scots pine and Norway spruce heat-treated at 170°C, 190°C, 200°C and 230°C. Holz Roh Werkst 64:192–197

Navi P, Sandberg D (2012) Thermo-hydro-mechanical processing of wood engineering sciences. EPFL Press, Lausanne

Phuong LX, Shida S, Saito T (2007a) Effect of heat treatment on brittleness of Styrax tonkinensis wood. J Wood Sci 53:181–186

Phuong LX, Takayama M, Shida S, Matsumoto Y, Aoyagi T (2007b) Determination of the accessible hydroxyl groups in heat-treated Styrax tonkinensis (Pierre) Craib ex Hartwich wood by hydrogen-deuterium exchange and 2H NMR spectroscopy. Holzforschung 61:488–491

Rautkari L, Kamke FA, Hughes M (2011) Density profile relation to hardness of viscoelastic thermal compressed (VTC) wood composite. Wood Sci Technol 45:693–705

Rautkari L, Hänninen T, Johansson L-S, Hughes M (2012) A study by X-ray photoelectron spectroscopy (XPS) of the chemistry of the surface of Scots pine (Pinus sylvestris L.) modified by friction. Holzforschung 66:93–96

Rautkari L, Laine K, Kutnar A, Medved S, Hughes M (2013a) Hardness and density profile of surface densified and thermally modified Scots pine in relation to degree of densification. J Mat Sci 48:2370–2375

Rautkari L, Hill CAS, Curling S, Jalaludin Z, Ormondroyd G (2013b) What is the role of the accessibility of wood hydroxyl groups in controlling moisture content? J Mat Sci 48:6352–6356

Rowell RM, Ellis WD (1978) Determination of dimensional stabilization of wood using the water-soak method. Wood Fiber Sci 10:104–111

Seborg RM, Tarkow H, Stamm A (1953) Effect of heat upon the dimensional stabilization of wood. For Prod J 3:59–67

Sivonen H, Maunu SL, Sundholm F, Jämsä S, Viitaniemi P (2002) Magnetic resonance studies of thermally modified wood. Holzforschung 56:648–654

Stamm AJ (1935) Shrinking and swelling of wood. Ind Eng Chem 21:401–406

Sundqvist B, Karsson O, Westermark U (2006) Determination of formic-acid concentrations formed during hydrothermal treatment of birch wood and its relation to colour, strength and hardness. Wood Sci Technol 40:549–561

Tjeerdsma BF, Boonstra M, Pizzi A. Tekely P, Militz H (1998) Characterisation of thermally modified wood: molecular reasons for wood performance improvement. Holz Roh Werkst 56:149–153

Torniainen P, Dagbro O, Morén T (2011) Thermal modification of birch using saturated and superheated steam. In: Proceedings of the 7th meeting of the Nordic-Baltic Network in Wood Material Science & Engineering (WSE), Oslo, Norway

Vainio-Kaila T, Rautkari L, Nordström K, Närhi M, Natri O, Kairi M (2013) Effect of extractives and thermal modification on antibacterial properties of Scots pine and Norway spruce. Int Wood Prod J. doi:10.1179/2042645313Y.0000000038

Welzbacher CR, Brischke C, Rapp OR (2007) Influence of treatment temperature and duration on selected biological, mechanical, physical and optical properties of thermally modified timber. Wood Mat Sci Eng 2:66–76

Willems W (2009) A Novel economic large-scale production technology for high-quality thermally modified wood. In: Proceedings of the 4th European Conference on Wood Modification, Stockholm, Sweden

Acknowledgments

Technical assistance of MSc Stefan Lehneke, financial support of the Finnish Foundation for Technology Promotion (Tekniikan edistämissäätiö) and the Puumiesten Ammattikasvatussäätiö are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rautkari, L., Honkanen, J., Hill, C.A.S. et al. Mechanical and physical properties of thermally modified Scots pine wood in high pressure reactor under saturated steam at 120, 150 and 180 °C. Eur. J. Wood Prod. 72, 33–41 (2014). https://doi.org/10.1007/s00107-013-0749-5

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-013-0749-5