Abstract

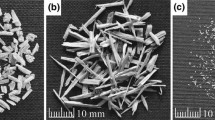

Flat pressed wood plastic composites were produced on a laboratory-scale using residues of lightweight foam core particleboards as raw material. Raw material preparation methods (dry blending and compounding with a twin screw extruder) and the wood flour content (WF) loading, as influencing parameters on the panel properties, were varied, and coupling agents (CA) were added in some variations. The results showed that panels produced with lower WF content (75 %) have better physical and mechanical properties compared to those of higher WF. The CAs only influenced the panel properties when they were added during the compounding of the materials. Due to the assumed higher wood degradation resulting from raw material compounding, the panel properties were inferior to the panels produced with dry blended materials.

Zusammenfassung

Produktionsabfälle von Leichtbau-Spanplatten mit Schaumkern wurden im Labormaßstab zu flachgepressten Holz-Polymer-Verbundwerkstoffe (WPC) weiterverarbeitet. Als Einflussparameter auf die Platteneigenschaften wurden die weitere Aufbereitung nach dem Zermahlen der Abfälle (Trockenmisch- und Doppelschnecken-Extruder-Verfahren) sowie der Holzanteil variiert. Einigen Varianten wurde Haftvermittler (CA) zugesetzt. Die Platten mit einem niedrigen Holzanteil (75 %) zeigten die besseren physikalischen und mechanischen Eigenschaften. Der Zusatz von Haftvermittler hat sich auf die Platteneigenschaften nur positiv ausgewirkt, wenn dieser vor dem Compoundieren zugegeben wurde. Aufgrund der thermischen und mechanischen Beanspruchung der Holzsubstanz im Extruder waren die Eigenschaften von Platten aus Trockenmischungen denen aus compoundierten Rohmaterialien überlegen.

Similar content being viewed by others

References

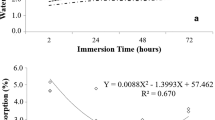

Adhikary KB, Pang S, Staiger MP (2008) Long-term moisture absorption and thickness swelling behavior of recycled thermoplastics reinforced with Pinus radiata sawdust. Chem Eng J 142:190–198

Ashori A, Nourbakhsh A (2009) Characteristics of wood–fiber plastic composites made of recycled materials. Waste Manag 29:1291–1295

Ayrilmis N, Jarusombuti S (2010) Flat-pressed wood plastic composite as an alternative to conventional wood-based panels. J Compos Mater 45:103–112

Ayrilmis N, Benthien JT, Thoemen H (2012) Effects of formulation variables on surface properties of wood plastic composites. Compos Part A Appl Sci Manuf 43:325–331

Balasuriya PW, Ye L, Mai Y-W (2001) Mechanical properties of wood flake–polyethylene composites. Part I: effects of processing methods and matrix melt flow behavior. Compos Part A Appl Sci Manuf 32:619–629

Benthien JT, Thoemen H (2012) Effects of raw materials and process parameters on the physical and mechanical properties of flat pressed WPC panels. Compos Part A Appl Sci Manuf 43:570–576

Benthien JT, Thoemen H, Mailkowski S, Lenz MT (2012) Resistance of flat-pressed wood–plastic composites to fungal decay: effects of wood flour content, density and manufacturing technology. Wood Fiber Sci 44:1–8

Bledzki AK, Mamun AA, Volk J (2010) Physical, chemical and surface properties of wheat husk, rye husk and soft wood and their polypropylene composites. Compos Part A Appl Sci Manuf 41:480–488

Butylina S, Martikka O, Kärki T (2011) Properties of wood fibre–polypropylene composites: effect of wood fibre source. Appl Compos Mater 18:101–111

Chaharmahali M, Tajvidi M, Kazemi NS (2008) Mechanical properties of wood plastic composite panels made from waste fiberboard and particleboard. Polym Compos 29:606–610

Chaharmahali M, Mirbagheri J, Tajvidi M, Kazemi NS, Mirbagheri Y (2010) Mechanical and physical properties of wood–plastic composite panels. J Reinf Plast Compos 29:310–319

Gardner DJ, Han Y, West C (2011) FRP-reinforced wood plastic composite panels for structural applications. In: Proceedings of the 11th international conference on wood and biofiber plastic composites and nanotechnology in wood composites symposium. USDA Forest Products Laboratory, Madison

Geimer RL, Clemons CM, WoodJr JE (1993) Density range of compression-molded polypropylene–wood composites. Wood Fiber Sci 25:163–169

Ichazo MN, Albano C, Gonzale J, Perera R, Candal MV (2001) Polypropylene/wood flour composites: treatments and properties. Compos Struct 54:207–214

Irle M, Barbu MC (2010) Wood-based panel technology. In: Thoemen H, Irle M, Sernek M (eds) Wood based panels—an introduction for specialists. Brunel University Press, London, pp 1–94

Lu JZ, Wu Q, Negulescu II (2004) Wood-fiber/high-density-polyethylene composites: compounding process. J Appl Polym Sci 93:2570–2578

Luedtke J, Welling J, Thoemen H, Barbu MC (2008) Development of a continuous process for the production of lightweight panel boards. In: Proceedings of the 8th international conference on sandwich structure, Porto

Myers GE, Clemons C, Balatinecz JJ, Woodhams RT (1992) Effects of composition and polypropylene melt flow on polypropylene–waste newspaper composites. In: Proceedings of the annual technical conference of the society of plastic engineers, Detroit, pp 602–604

Niska KO, Sain M (2008) Wood–polymer composites. Woodhead Publishing Ltd, Cambridge

Nygard P, Tanem BS, Karlsen T, Brachet P, Leinsvang B (2008) Extrusion-based wood fibre–PP composites: wood powder and pelletized wood fibres—a comparative study. Compos Sci Technol 68:3418–3427

Poletto M, Dettenborn J, Zeni M, Zattera AJ (2011a) Characterization of composites based on expanded polystyrene wastes and wood flour. Waste Manag 31:779–784

Poletto M, Zeni M, Zattera AJ (2011b) Effects of wood flour addition and coupling agent content on mechanical properties of recycled polystyrene/wood flour composites. J Thermoplast Compos Mater. doi:10.1177/0892705711413627

Rowell RM, Youngquist JA, Mcnatt D (1991) Composite from recycled materials. In: Proceedings of the 25th international particleboard/composite materials symposium. Washington State University, Washington, pp 301–314

Sanadi AR, Hunt JF, Caulfield DF (2001) High fiber-low matrix composites: kenaf fiber/polypropylene. In: Proceedings of the 6th international conference on woodfiber–plastic composites, Madison, pp 121–124

Shalbafan A, Luedtke J, Welling J, Thoemen H (2012a) Comparison of foam core materials in innovative lightweight wood-based panels. Eur J Wood Prod 70:287–292

Shalbafan A, Welling J, Luedtke J (2012b) Effect of processing parameters on mechanical properties of lightweight foam core sandwich panels. Wood Mater Sci Eng 7:69–75

Wolcott MP (2003) Formulation and process development of flat pressed wood–polyethylene composites. For Prod J 53:25–32

Yang H-S, Wolcott MP, Kim H-J, Kim S, Kim H-J (2007) Effect of different compatibilizing agent on the mechanical properties of lignocellulosic material filled polyethylene bio-composites. Compos Struct 79:369–375

Zabihzadeh SM, Dastoorian F, Ebrahimi G (2010) Effect of wood species and coupling agent on mechanical properties of wood flour/HDPE composites. J Reinf Plast Compos 29:1146–1152

Acknowledgments

Ali Shalbafan wishes to thank the Ministry of Science, Research and Technology of Iran for awarding him a scholarship to pursue his education towards a Ph.D. The authors are grateful to B.Sc. Christoph Breitmar, University of Hamburg, for preparing the test samples. The authors express their sincere thanks to Dr. Andreas Krause, University of Göttingen, for his kind support in compounding the test materials.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shalbafan, A., Benthien, J.T., Welling, J. et al. Flat pressed wood plastic composites made of milled foam core particleboard residues. Eur. J. Wood Prod. 71, 805–813 (2013). https://doi.org/10.1007/s00107-013-0745-9

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-013-0745-9