Abstract

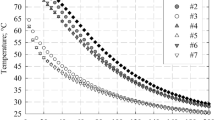

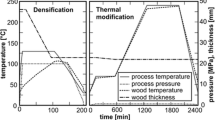

The heat distribution during thermal modification of beech (Fagus sylvatica L.) and spruce (Picea abies L. Karst) wood with dimensions of 80 × 80 × 200 mm3 has been investigated. Heat distribution was continuously measured by thermocouples in longitudinal and transverse directions. Significant temperature gradients occur in the initial phase of the process as well as during the modification phase (set temperature 200 °C for 3 h), where ongoing chemical reactions in wood were taking place. Thus, the temperature in the investigated positions increased to 240 °C (beech) and 215 °C (spruce). The mentioned properties should be taken into account when optimizing the heat treatment process (quality control, energy savings, etc.).

Similar content being viewed by others

References

Babiak M (1996) Temperature profiles in wood. Drevársky výskum 41(1):3–14

Gryc V, Vavrčík H, Gomola Š (2008) Selected Properties of European Beech (Fagus sylvatica L.). J For Sci 54(9):418–425

Hill C (2006) Wood modification chemical. Thermal and other processes. Wiley series in renewable resources. John Wiley & Sons Ltd, USA

Johansson D, Moren T (2005) The potential of colour measurement for strength prediction of thermally treated wood. Holz Roh Werkst 64(2):104–110

Kim D, Nishiyama Y, Wada M, Kuga S, Okano T (2005) Thermal decomposition of cellulose crystallites in wood. Holzforschung 55(5):521–524

Shi JL, Kocaefe J, Zhang J (2007) Mechanical behaviour of Québec wood species heat-treated using thermowood process. Holz Roh Werkst 65(4):255–259

Soltes EJ, Elder TJ (1981) Organic Chemicals from Biomass. CRC Press, Pyrolysis, pp 63–95

Younsi R, Kocaefe D, Poncsak S, Kocaefe Y, Gastonguay L (2008) CFD modeling and experimental validation of heat and mass transfer in wood poles subjected to high temperatures: a conjugate approach. Heat Mass Transf 44(12):1497–1509

Acknowledgments

This work was funded by the European Social Fund and the state budget of the Czech Republic, project “The Establishment of an International Research Team for the Development of New Wood-based Materials” reg. no. CZ.1.07/2.3.00/20.0269.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Čermák, P., Horáček, P. & Rademacher, P. Heat distribution in thermally modified timber. Eur. J. Wood Prod. 71, 827–830 (2013). https://doi.org/10.1007/s00107-013-0739-7

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-013-0739-7