Abstract

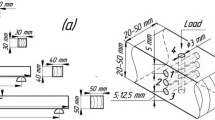

The effect of drilling on the permeability of Japanese cedar and the bending properties of resin treated compressed wood were examined. Compressed wood was manufactured by impregnating aqueous phenolic resin solutions into the heartwood through drilled holes and polymerizing the impregnated resins using a hot press to maintain the deformation. The compressive deformation was carried out at 150°C for 1 h to one-half of the original specimen thickness. A dye solution permeated the entire specimen when the density of drilled holes exceeded approximately 5000 holes/m2. When the compressed wood was manufactured under the drilling condition, the resin type was found to greatly affect the bending strength and the failure mode of the specimens in bending test.

Zusammenfassung

Der Einfluss gebohrter Löcher auf die Permeabilität von japanischer Zeder und die Biegeeigenschaften von mit Harz imprägniertem Pressholz wurden untersucht. Das Pressholz wurde hergestellt, indem wässrige Phenolharzlösungen über gebohrte Löcher in das Kernholz eingebracht und mittels Heißpressung polymerisiert wurden, um die Verformung zu stabilisieren. Das Holz wurde bei 150°C für die Dauer einer Stunde auf die Hälfte der ursprünglichen Prüfkörperdicke gepresst. Mittels einer gefärbten Lösung wurde gezeigt, dass der Prüfkörper ab einer Lochdichte von mindestens 5000 Löchern/m2 vollständig imprägniert war. Bei so hergestelltem Pressholz hatte der Harztyp einen großen Einfluss auf die Biegefestigkeit und das Bruchbild des Prüfkörpers im Biegeversuch.

Similar content being viewed by others

References

Bryant BS (1966) The chemical modification of wood from the point of view of wood science and economics. For Prod J 16(2):20–27

Fukuta S, Takasu Y, Sasaki Y, Hirashima Y (2007) Compressive deformation process of Japanese cedar (Cryptomeria Japonica). Wood Fiber Sci 39(4):548–555

Fukuta S, Asada F, Sasaki Y (2008a) Manufacture of compressed wood fixed by phenolic resin impregnation through drilled holes. J Wood Sci 54(2):100–106

Fukuta S, Asada F, Sasaki Y (2008b) The simultaneous treatment of compression drying and deformation fixation in the compression processing of wood. For Prod J 58(7/8):82–88

Fukuta S, Asada F, Sasaki Y (2008c) Influence of drilled holes on bending properties of compressed wood manufactured by new process. For Prod J 58(10):19–24

Furuno T, Imamura Y, Kajita H (2004) The modification of wood by treatment with low molecular weight phenol-formaldehyde resin: a properties enhancement with neutralized phenolic-resin and resin penetration into wood cell walls. Wood Sci Technol 37(5):349–361

Higuchi M (2006) Impregnation of wood with phenolic resin. Suppression of physical deterioration protects wood from termite-attack and decay. Wood Ind 61(6):238–243

Inoue M, Norimoto M, Otsuka Y, Yamada T (1991a) Surface compression of coniferous wood lumber II. Permanent set of compression wood by low molecular weight phenolic resin and some physical properties of the products. Mokuzai Gakkaishi 37(3):227–233

Inoue M, Norimoto M, Otsuka Y, Yamada T (1991b) Surface compression of coniferous wood lumber III. Permanent set of the surface compressed layer by a water solution of low molecular weight phenolic resin. Mokuzai Gakkaishi 37(3):234–240

Inoue M, Norimoto M, Tanahashi M, Rowel RM (1993a) Steam or heat fixation of compressed wood. Wood Fiber Sci 25(3):224–235

Inoue M, Ogata S, Kawai S, Rowell RM, Norimoto M (1993b) Fixation of compressed wood using melamine-formaldehyde resin. Wood Fiber Sci 25(4):404–410

Inoue M, Minato K, Norimoto M (1994) Permanent fixation of compressive deformation of wood by crosslinking. Mokuzai Gakkaishi 40(9):931–936

Itoh T, Ishihara S (1997) Compressive deformation of wood using hot rollpress and its fixation by glyoxal resin. Mokuzai Gakkaishi 43(1):52–60

Kubota M, Umehara K, Kikuchi S, Hirabayashi Y (1998) Manufacture of phenolic resin impregnated compressed wood by use of high-pressure steamed Japanese larch lumber and properties of the products. J Hokkaido For Prod Res Inst 12(3):1–9

Ott LR, Longnecker MT (2000) An introduction to statistical methods and data analysis. Duxbury, Pacific Grove, pp 427–468, 943–974

Ryu JY, Takahashi M, Imamura Y, Sato T (1991) Biological resistance of phenol-resin treated wood. Mokuzai Gakkaishi 37(9):852–858

Ryu JY, Imamura Y, Takahashi M, Kajita H (1993) Effect of molecular weight and some other properties of resins on the biological resistance of phenol-resin treated wood. Mokuzai Gakkaishi 39(4):486–492

Shoho S (2007) Development of highly durable exterior wooden materials from domestic timber species by impregnation of phenol resin. Wood Preserv 33(3):126–131

Stamm AJ, Seborg RM (1951) Resin-treated laminated, compressed wood-Compreg. Rep No 1381. USDA, Forest Service, Forest Products Laboratory, Madison, WI

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fukuta, S., Watanabe, A., Akahori, Y. et al. Bending properties of compressed wood impregnated with phenolic resin through drilled holes. Eur. J. Wood Prod. 69, 633–639 (2011). https://doi.org/10.1007/s00107-010-0506-y

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-010-0506-y