Abstract

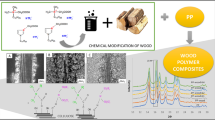

Ionic liquid of 1-(2-hydroxylethyl)-3-ethyl imidazolium chloride ([HeEIM]Cl) was synthesized and its chemical structure was examined by FTIR and 1HNMR. Dissolution of the fir powder which was activated with 25% NaOH under different conditions in the ionic liquid was studied. Acrylamide (AM) was grafted onto the dissolved fir powder in [HeEIM]Cl and aqueous medium, respectively. Technologic conditions for graft copolymerization were optimized by orthogonal test. The results showed that the ionic liquid exhibited good solubility for the fir powder, the dissolution rate was as high as 18.3%. The graft copolymer prepared in [HeEIM]Cl had higher grafting degree and grafting efficiency than in aqueous medium. The most suitable conditions for graft copolymerization were: mass fraction of AM 25%, fluid ratio of [HeEIM]Cl to wood 30:1, and mass proportion of wood to AM 1:4. FTIR and SEM suggested that AM had been grafted onto the fir powder. XRD and TG indicated that the crystalline structure of the wood fiber had been destroyed thoroughly after being grafted, and the thermal stability of graft copolymer had been improved.

Zusammenfassung

Die ionische Flüssigkeit 1-(2-Hydroxyethyl)-3-ethyl-imidazolchlorid ([HeEIM]Cl) wurde synthetisiert und ihre chemische Struktur wurde mittels FTIR und 1HNMR überprüft. Die Auflösung von Tannenholzmehl, das mit 25 % NaOH unter unterschiedlichen Bedingungen aktiviert worden war, wurde in ionischer Flüssigkeit untersucht. Acrylamid (AM) wurde auf das aufgelöste Tannenholzmehl in [HeEIM]Cl sowie in einem wässrigen Medium aufgepfropft. Mittels orthogonaler Versuche wurden die technologischen Bedingungen der Pfropfcopolymerisation optimiert. Die Ergebnisse zeigten, dass die ionische Flüssigkeit für die Auflösung von Tannenholzmehl gut geeignet war. Die Auflösungsrate betrug bis zu 18,3 %. Das in [HeEIM]Cl hergestellte Pfropfcopolymer wies einen höheren Pfropfgrad und eine höhere Pfropfeffizienz auf als dasjenige, das in wässrigem Medium hergestellt worden war. Die am besten geeigneten Bedingungen einer Propfcopolymerisation ergaben sich bei einem Massenanteil von AM von 25 %, einem Flüssigkeitsverhältnis von [HeEIM]Cl zu Holz von 30:1 und einem Massenverhältnis von Holz zu AM von 1:4. FTIR- und REM-Untersuchungen lassen darauf schließen, dass AM auf das Tannenholzmehl gepfropft wurde. Röntgendiffraktometrie (XRD) und thermogravimetrische Analyse (TG) zeigten, dass die kristalline Struktur der Holzfaser nach der Pfropfung vollkommen zerstört worden war und sich die Wärmebeständigkeit des Pfropfcopolymers verbessert hatte.

Similar content being viewed by others

References

Dizhbite T, Telyshera G (1998) Multifunctional activity of lignin derivatives in pulp/filler compositions. In: Adv lignocellul chem ecol friendly pulping bleaching technol, Eur workshop lignocellul pulp 11, pp 97–100

Faix O (1988) Practical uses of FTIR spectroscopy in wood science and technology. Mikrochim Acta [Wien] 1:21–25

Fort DA, Remsing RC, Swatloski RP, Moyna P, Moyna G, Rogers RD (2007) Can ionic liquids dissolve wood? Processing and analysis of lignocellulosic materials with 1-n-butyl-3-methylimidazolium chloride. Green Chem 9:63–69

Guo LY, Shi TJ, Li Z, Duan YP (2008a) Solubility of two kinds of imidazolium ionic liquids for fir powder. J Chem Ind Eng 59:1299–1304

Guo LY, Shi TJ, Li Z, Duan YP, Wang YG (2008b) Synthesis of novel and functionalized ionic liquid [HeEIM]Cl and its solubility for cotton fiber. Chem J Chin Univ 29:1901–1907

Kilpeläinen I, Xie HB, King A, Granstrom M, Heikkinen S, Argyropoulos DS (2007) Dissolution of wood in ionic liquids. J Agric Food Chem 55:9142–9148

Kubisa P (2004) Application of ionic liquids as solvent for polymerization processes. Prog Polym Sci 29:3–12

Liu S, Sun G (2008) Radical graft functional modification of cellulose with allyl monomers: chemistry and structure characterization. Carbohydr Polym 71:614–625

Lu XB, Yao X, Hu JQ, Wang ZP, Li JH (2006a) Composite system based on chitosan and room-temperature ionic liquid: direct electrochemistry and electrochemistry and electrocatalysis of hemoglobin. Biomacromolecules 7:975–980

Lu XB, Zhang Q, Zhang L, Li JH (2006b) Direct electron transfer of horseradish peroxidase and its biosensor based on chitosan and room temperature ionic liquid. Electrochem Commun 8:874–878

Pandey KK, Pitman AJ (2003) FTIR studies of the changes in wood chemistry following decay by brown-rot and white-rot fungi. Int Biodeterior Biodegrad 52:151–160

Scurtoa M, Leitner W (2006) Expanding the useful range of ionic liquids: melting point depression of organic salts with carbon dioxide for biphasic catalytic reactions. Chem Commun 35:3681–3683

Seven P, Coskun M, Demirelli K (2008) Synthesis and characterization of two-armed graft copolymers prepared with acrylate and methacrylate using atom transfer radical polymerization. React Funct Polym 68:922–930

Swatloski RP, Spear SK, Holbrey JD, Rogers RD (2002) Dissolution of cellulose with ionic liquids. J Am Chem Soc 124:4974–4975

Vogli E, Sieber H, Greil P (2002) Biomorphic SiC-ceramic prepared by Si-vapor phase infiltration of wood. J Eur Ceram Soc 22:2663–2668

Wang YL, Cheng BW, Zhao JS (2002) Cellulose activation. J Tianjin Polytech Univ 21:83–86

Wang Y, He J, Lu T, Wu YY, Fan YM (2004) Research on graft copolymerization of cellulose. Fine Spec Chem 12:18–21

Weuster-Botz D (2007) Process intensification of whole-cell biocatalysis with ionic liquids. Chem Rec 7:334–340

Xue ZH, Zhao GJ (2007) Influence of different treatments on wood crystal properties. J Northwest For Univ 22:169–171

Zein El-Abedin S, Endres F (2006) Electrodeposition of metals and semiconductors in air- and water-stable ionic liquids. Chem Phys Chem 7:58–61

Zhang H, Wu J, Zhang J, He JS (2005) 1-Allyl-3-methylimidazolium chloride room temperature ionic liquid: a new and powerful nonderivatizing solvent for cellulose. Macromolecules 38:8272–8277

Acknowledgements

The authors gratefully acknowledge the support of the National Natural Science Foundation of China (NSFC) (Grant No.50773017).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Guo, L., Shi, T. & Li, Z. Dissolution of fir powder and its graft copolymer in ionic liquid. Eur. J. Wood Prod. 69, 383–389 (2011). https://doi.org/10.1007/s00107-010-0438-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-010-0438-6