Abstract

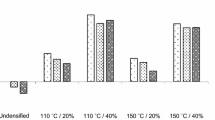

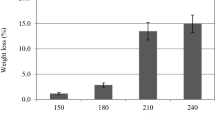

Low-density hybrid poplar (Populus deltoides × Populus trichocarpa) was densified with the viscoelastic thermal compression (VTC) process to three different degrees of densification (63%, 98%, and 132%). Durability of the VTC treated specimens was assessed by exposure to two white rot fungi (Pleurotus ostreatus and Trametes versicolor) for four or eight weeks. After incubation, mass loss in grams and percentage mass loss were determined. The results showed that VTC densification did not change decay resistance to Pleurotus ostreatus and Trametes versicolor. The mass losses caused by Trametes versicolor were more extensive than those by Pleurotus ostreatus. As expected, longer exposure time resulted in higher mass loss. Furthermore, the degree of densification did not influence susceptibility to fungal degradation.

Similar content being viewed by others

References

Blanchette RA, Obst JR, Timell TE (1994) Biodegradation of compression wood and tension wood by white and brown rot fungi. Holzforschung 48:34–42

Bravery AF (1978) A miniaturised wood-block test for rapid evaluation of wood preservative fungicides. IRG-Document IRG/WP 2113, Stockholm, Sweden

Kamke FA (2006) Densified radiata pine for structural composites. Maderas, Cien Technol 8(2):83–92

Kamke FA, Sizemore H (2008) Viscoelastic thermal compression of wood. US Patent Application No. 7.404.422

Kutnar A, Kamke FA, Sernek M (2008a) The mechanical properties of densified VTC wood relevant for structural composites. Holz Roh- Werkst 66(6):439–446

Kutnar A, Kamke FA, Nairn JA, Sernek M (2008b) Mode II fracture behavior of bonded viscoelastic thermal compressed wood. Wood Fibre Sci 40(3):362–373

Kutnar A, Kamke FA, Petrič M, Sernek M (2008c) The influence of viscoelastic thermal compression on the chemistry and surface energetics of wood. Colloids Surf A: Physicochem Eng Aspects 329:82–86

Kutnar A, Kamke FA, Sernek M (2009) Density profile and morphology of viscoelastic thermal compressed wood. Wood Sci Technol 43(1):57–68

Skyba O, Niemz P, Schwarze FWMR (2008) Degradation of thermo-hygro-mechanically (THM)-densified wood by soft-rot fungi. Holzforschung 62(3):277–283

Skyba O, Niemz P, Schwarze FWMR (2009) Resistance of thermo-hygro-mechanically (THM)-densified wood to degradation by white rot fungi. Holzforschung 63:639–646

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kutnar, A., Humar, M., Kamke, F.A. et al. Fungal decay of viscoelastic thermal compressed (VTC) wood. Eur. J. Wood Prod. 69, 325–328 (2011). https://doi.org/10.1007/s00107-010-0432-z

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-010-0432-z