Abstract

Medium density fiberboard (MDF) is a wood based panel which main feature is the distribution of wood fibers, uniform and dense in the full panel thickness, allowing for very precise machining on the edges and in the faces of the board. However, and due to its manufacturing process, a density profile is produced with external layers being heavier than the core of the panel. These differences generate a variable surface quality across the panel when machined.

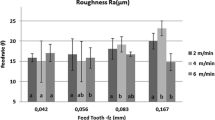

The tool characteristics and the cutting process kinematics also determine the resulting surface roughness of the processed material. With regard to the cutting energy, there are important variations when machining conditions are modified, or when some tool characteristics are changed.

The aim of this paper is to determine the cutting energy required to rip sawing MDF and to study its relationship with the resulting surface roughness across the panel profile when the density of the material changes.

The findings lead to the conclusion that there is a close relationship between cutting energy and surface roughness, being particularly sensitive to changes in specific gravity within the profile of the panel, and in particular to changes in cutting condition expressed as mean chip thickness.

Zusammenfassung

Mitteldichte Faserplatten (MDF) sind Holzwerkstoffplatten mit einheitlicher und dichter Verteilung der Holzfasern im gesamten Plattenquerschnitt. Dies ermöglicht eine sehr präzise Bearbeitung der Kanten und der Flächen der Platten. Jedoch entsteht aufgrund des Herstellungsverfahrens ein Dichteprofil, bei dem die äußeren Schichten dichter sind als die Mittelschicht. Diese Unterschiede haben zur Folge, dass bei der Bearbeitung die Oberflächenqualität der Schmalseiten variiert.

Die Werkzeugeigenschaften und die Kinematik des Schneidverfahrens haben ebenfalls Einfluss auf die Oberflächenrauheit des bearbeiteten Materials. Änderungen der Bearbeitungsbedingungen oder der Werkzeugeigenschaften führen zu signifikanten Unterschieden der Schneidenergie.

Ziel dieser Arbeit ist die Bestimmung der zum Längsschneiden von MDF benötigten Schneidenergie sowie die Untersuchung des Zusammenhangs mit der Oberflächenrauheit der Schmalseiten bei variierender Materialdichte.

Die Ergebnisse lassen den Schluss zu, dass zwischen der Schneidenergie und der Oberflächenrauheit ein enger Zusammenhang besteht. Einen besonders großen Einfluss haben die Variationen der Dichte im Plattenquerschnitt sowie die mittlere Spandicke als Maß der Schneidbedingungen.

Similar content being viewed by others

References

Aguilera A, Méausoone PJ, Martin P (2000) Wood material influence in routing operations: the MDF case. Holz Roh- Werkst 58(4):278–283

Aguilera A, Vega M, Meausoone PJ (2007) Effects of grain angle on the amplitudes of acoustic emission and surface roughness in wood machining. Wood Sci Technol 41:373–381

Akbulut T, Ayrilmis N (2006) Effect of compression wood on surface roughness and surface absortion of médium density fiberboard. The Finnish Society of Forest Science. Silva Fenn 40(1):161–167

Davim JP, Clemente VC, Silva S (2009) Surface roughness aspects in milling MDF (medium density fiberboard). Int J Adv Manuf Tech. doi: 10.1007/s00170-007-1318-z

Davim JP, Gaitonde VN, Karnik SR (2008) An investigative study of delamination in drilling of medium density fiberboard (MDF) using response surface models. Int J Adv Manuf Tech 37(1–2):49–57

Dippon J, Ren H, Amara FB, Altintas Y (2000) Orthogonal cutting mechanics of medium density fiberboards. Forest Prod J 50:25–30

Engin S, Altintas Y, Amara FB (2000) Mechanics of routing medium density fiberboard. Forest Prod J 50:65–69

Hiziroglu S, Kosonkorn P (2006) Evaluation of surface roughness of Thai medium density fiberboard. Build Environ 41:527–533

International Standard ISO 4287 (1997) Geometrical product specifications (GPS) – surface texture: profile method – terms, definitions and surface texture parameters. International Organization for Standardization, Geneva, Switzerland

Juan J (1992) Comment bien usiner le bois. CTBA, Paris, pp 140

Kilic M, Hiziroglu S, Burdurlu E (2006) Effect of machining on surface roughness of wood. Build Environ 41:1074–1078

Kivimaa E (1950) Cutting force in wood-working. The State Institute for Technical Research, Finland, Julkaisu 18 Publication, p 102

Lin RJ, Van Houts J, Bhattacharyya D (2006) Machinability investigation of medium density fiberboard. Holzforschung 60:71–77

McKenzie WM, Ko P, Cvitkovic R, Ringler M (2001) Towards a model predicting cutting forces and surface quality in routing layered boards. Wood Sci Technol 35:563–569

Murase Y (1994) Acoustic emission monitoring in wood machining process. In: Proceedings of the 5th International Joint Seminar on the Future of Agricultural Science in Japan and Korea, October 17–20. Faculty of Agriculture, Kyushu University

Tanaka C (1991) Relationship between surface finish quality and acoustic emission count rate in circular sawing. In: Proceedings of the 10th International Wood Machining Seminar, October 21–23. University of California, Forest Products Laboratory, Richmond California, pp 308–316

Zhao C, Tanaka C, Nakao T, Takahashi A (1991) Relationships between surface finish qualities and acoustic emission count rates in circular sawing II. Mokuzai Gakkaishi 37(5):434–440

Acknowledgements

We would like to thank the wood science student Mr. Eder PARDO for his support and cooperation in the execution of the trials, data collection and sample preparation, which made possible this study; we also acknowledge the cooperation of the Direction of Research and Development (DID) of the Universidad Austral de Chile.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Aguilera, A. Cutting energy and surface roughness in medium density fiberboard rip sawing. Eur. J. Wood Prod. 69, 11–18 (2011). https://doi.org/10.1007/s00107-009-0396-z

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-009-0396-z