Abstract

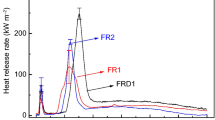

Intumescent material with commercial resin, such as styrene acrylic copolymer resin, has been demonstrated to be extremely effective in improving the fire performance of wooden materials used for indoor furnishing. The formulation of the coating is a key to its ability to improve flame retardance. This study investigates the enhancement for painted thin red lauan (Parashorea spp.) plywood. The ability of the material to retard flame arises due to the interactions between the four major components of intumescent formulation: (1) a binder resin (BR), styrene acrylic emulsion resin, (2) a carbonizing substance (CS), pentaerythritol (3) a foam producing substance (FPS), melamine and (4) a dehydrating agent (DA), ammonium polyphosphate. This paper compares the fire performance of the plywood when coated with resin of differing BR/CS ratios (designated as the FRS series) and FPS/DA ratios (designated as the FRD series), by means of a cone calorimeter. These intumescent formulations significantly enhanced the fire retardancy of painted plywood, exhibiting lower peak heat release rates, higher expansion of the intumescent layer and longer time to peak heat release rates (PHRR), when compared to plywood panels coated with sole binder resin. However, worse performance was presented when compared with the data for uncoated plywood panels if the intumescent was produced by equal ratio of the four components. Therefore, the formulation of the intumescent is important. Additionally, lower BR contents in the FRS series and lower FPS contents in the FRD series further enhanced flame retardancy. Advanced investigation by IR and 31P NMR demonstrated that lower BR and FPS content extends the survival duration of the phosphor-carbonaceous structure of chars. The findings in this study enhance the state-of-the-art understanding of the effect of the intumescent.

Zusammenfassung

Schaumschichtbildner mit handelsüblichem Harz, wie zum Beispiel Styrol-Acryl Kopolymerharz, haben sich als äußerst effektiv zur Verbesserung des Brandverhaltens von im Innenausbau verwendeten Holzprodukten erwiesen. Entscheidend für die Brandschutzwirkung ist die Rezeptur der Beschichtung. Dies wurde hier am Beispiel von beschichtetem dünnen Lauansperrholz (Parashorea spp.) untersucht. Die flammenhemmende Eigenschaft ist auf das Zusammenwirken der vier Hauptkomponenten von schaumschichtbildenden Beschichtungen zurückzuführen: 1) einem Harzbinder (BR), Styrol-Acryl-Emulsionsharz, 2) einer verkohlungswirkenden Substanz (CS) Pentaerythrit, 3) einer Schaum bildenden Substanz (FPS) Melamin, und 4) einem Entwässerungsmittel (DA) Ammoniumpolyphosphat. In dieser Studie wird mit Hilfe von Kone-Kalorimeter Messungen das Brandverhalten des Sperrholzes untersucht, das mit Harz mit unterschiedlichen BR/CS-Anteilen (als FRS-Serie bezeichnet) und PFS/DA-Anteilen (als FRD-Serie bezeichnet) beschichtet worden ist. Diese schaumschichtbildenden Beschichtungen haben den Feuerwiderstand von beschichtetem Sperrholz signifikant erhöht. Im Vergleich zu nur mit Harzbinder beschichteten Sperrholzplatten ergaben sich dabei geringere Peaks für die Wärmefreisetzungsraten, eine höhere Ausbreitung der schaumschichtbildenden Schicht und eine längere Dauer bis zum Erreichen der maximalen Wärmefreisetzungsrate (PHRR). Brandschutzbeschichtungen mit gleichen Anteilen aller vier Komponenten zeigten im Vergleich zu den unbeschichteten Sperrholzplatten jedoch ein schlechteres Verhalten. Deswegen spielt die Rezeptur der Brandschutzbeschichtung eine wichtige Rolle. Des Weiteren zeigte sich, dass ein niedrigerer BR-Gehalt in den FRS-Serien und ein niedrigerer FPS-Gehalt in den FRD-Serien die Flammenhemmung weiter verbesserten. Untersuchungen mittels IR und 31P NMR ergaben, dass ein niedrigerer BR- und FPS-Gehalt die Überlebensdauer der Phosphor-Karbonstruktur der verkohlten Schicht verlängert hat. Die Ergebnisse dieser Studie geben einen tieferen Einblick in die Wirkung einer Brandschutzbeschichtung.

Similar content being viewed by others

References

ASTM standard E1354-99 (1999) Standard Test Method for Heat and Visible Smoke Release Rates for Materials and Products Using an Oxygen Consumption Calorimeter. American Society for Testing and Materials, West Conshohoken, PA

Baljinder KK, Horrocks AR (1996) Complex char formation in flame-retarded fire-intumescent combinations-II. thermal analytical studies. Polym Degrad Stabil 54:289–303

Bourbigot S, Le Bras M, Delobel R, Amourex JP (1996) Synergistic effect of zeolite in an intumescent process: Study of the carbonaceous structures using solid-state NMR. J Chem Soc Faraday Trans 92:149–158

Bourbigot S, Le Bras M, Dabrowski F, Gilman JW, Kashiwagi T (2000) PA-6 clay nanocomposite hybrid as char forming agent in intumescent formulations. Fire Mater 24:201–208

Bourbigot S, Le Bras M, Duquesne S, Rochery M (2004) Recent advances for intumescent polymers. Macromol Mater Eng 289:499–511

Camino G, Costa L, Trossarelli L (1985) Study of the mechanism of intumescence in fire retardant polymers: Part VI – mechanism of ester formation in ammonium polyphosphate-pentaerythritol mixtures. Polym Degrad Stabil 12:213–228

Chinese National Standard CNS 6532 (1993) Method of test for the fire-resistibility of internal decorative material of building. National Standard Bureau, Taipei, Taiwan

Chuang CS, Tsai KC, Wang MK, Ou CC, Ko CH (2008) Effects of intumescent formulation for acrylic-based coating on flame-retardancy of painted red lauan (Parashorea spp.) thin plywood. Wood Sci Technol 42:593–607

Chuang HB, Wang SY (2002) Effects of retention and distribution of fire retardant chemical on performance of fire retardant treated China fir (Cunninghamia lanceolata) wood. Holzforschung 56:209–214

Demir H, Arkis E, Balköse D, Ülkü S (2005) Synergistic effect of natural zeolites on flame retardant additives. Polym Degrad Stabil 89:478–483

Drevelle C, Duquesne S, Le Bras M, Lefebvre J, Delobel R, Castrovinci A, Magniez C, Vouters M (2004) Influence of ammonium polyphosphate on the mechanism of thermal degradation of an acrylic binder resin. J Appl Polym Sci 94:717–729

Duncan TM, Douglass DC (1984) On the 31P chemical shift anisotropy in condensed phosphates. Chem Phys 87:339–349

Gao M, Sun CY, Wang CX (2006) Thermal degradation of wood treated with flame retardants. J Therm Anal Calorim 85:765–769

Horrocks AR, Price D (2001) Fire retardant materials. Woodhead Publishing Limited, Abington, Cambridge, pp 1–30

Lindsay CI, Hill SB, Hearn M, Manton G, Everall N, Bunn A, Heron J, Fletcher I (2000) Mechanisms of action of phosphorus based flame retardants in acrylic polymers. Polym Intell 49:1183–1192

Le Bras M, Bourbigot M (1999) Comprehensive study of the degradation of an intumescent EVA-based material during combustion. J Mater Sci 34:5777–5782

Mitchell S (1993) Fire performance of wood: Test methods and fire retardant treatments. In: Proceedings of the 4th Annual BCC Conference on Flame Retardancy, 18–20 May, Stamford, CT. Business Communications Co. Norwalk, CT

SAS Institute Inc. (1994) Statistical Analysis Software for Microcomputer. SAS Institute Inc., Cary, NC

Wladyka-Przbylak M, Kozlowski R (1999) The thermal characteristics of different intumescent coatings. Fire Mater 23:33–43

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chuang, CS., Tsai, KC., Wang, MK. et al. Impact of the intumescent formulation of styrene acrylic-based coatings on the fire performance of thin painted red lauan (Parashorea spp.) plywood . Eur. J. Wood Prod. 67, 407–415 (2009). https://doi.org/10.1007/s00107-009-0338-9

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-009-0338-9