Abstract

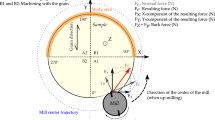

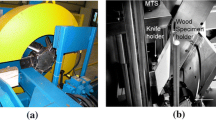

Peripheral milling with up-milling and down-milling techniques is very well known from a geometrical point of view. However, in processing anisotropic materials such as wood these geometrical aspects imply relevant differences when machining. In fact milling anisotropic materials leads to different cutting geometries when up-milling or down-milling and when changing the depth of cut. This results in a relative orientation of the grain depending on the process adopted. In this paper the geometrical interactions between tool and wood grain have been analysed theoretically and supported by experimental evidence. To achieve this result, Douglas fir has been processed with different depths of cut and grain orientations, the resulting chips have been collected and analysed. The experiments show how a shift of the cutting phenomenon and the chip type can be observed to support the theoretical background.

Zusammenfassung

Die geometrischen Aspekte beim Umfangfräsen mittels Gleichlauf- und Gegenlauffräsung sind sehr bekannt. Allerdings treten bei der Zerspanung von anisotropen Materialien wie z. B. Holz erhebliche Unterschiede auf. Tatsächlich führt das Fräsen von anisotropen Materialien beim Gleichlauf- und Gegenlauffräsen sowie bei einer Änderung der Frästiefe zu unterschiedlichen Schneidgeometrien. Die Ursache ist die jeweilige Orientierung des Faserverlaufs in Abhängigkeit des angewandten Verfahrens. In dieser Studie wurden die geometrischen Interaktionen zwischen Werkzeug und Faserverlauf theoretisch analysiert und mittels experimenteller Ergebnisse bestätigt. Dazu wurde Douglasienholz bei unterschiedlichem Faserverlauf und mit unterschiedlichen Frästiefen bearbeitet und die erzeugten Späne wurden analysiert. Die bei den jeweiligen Fräsverfahren experimentell ermittelten Spanformen bestätigen die theoretischen Annahmen.

Similar content being viewed by others

References

Cyra G, Tanaka C (2000) The effects of wood fiber directions on acoustic emission in routing. Wood Sci Technol 34:237–252

Franz NC (1958) An analysis of the wood cutting process. PhD Thesis, University Michigan, Ann Arbor

Goli G, Bleron L, Marchal R, Uzielli L, Negri M (2002) Formation and quality of wood surfaces processed at various grain angles – Douglas fir and oak. Wood Struct Prop 02:91–98

Goli G, Marchal R, Uzielli L, Negri M (2003) Measuring cutting forces in routing wood at various grain angles. Study and comparison between up and down-milling techniques, processing Douglas fir and oak. Proceedings of the 16th International Wood Machining Seminar, Matsue, August 24–30, pp 127–137

Goli G, Marchal R, Uzielli L (2004a) Classification of wood surface defects according to their mechanical formation during machining. Proceedings of the 2nd International Symposium on Wood Machining, Vienna, July 5–7, pp 315–324

Goli G, Uzielli L (2004b) Mechanisms of wood surface formation and resulting final condition after planing. Proceedings of the 2nd International Symposium on Wood Machining, Vienna, July 5–7, pp 451–457

Goli G, Fioravanti M, Sodini N, Jiangang Z, Uzielli L (2005) Wood Processing: a contribute to the interpretation of surface origin according to grain orientation. Proceedings of the 17th International Wood Machining Seminar, Rosenheim, September 26–28, pp 44–54

Kivimaa E (1950) Cutting force in woodworking. State institute for Technical Research, VTT Publication No. 18

Koch P (1972) Utilization of the southern pines Vol. II, U.S. Department of Agriculture-Forest Service

Juan J (2000) Wood machining technology. CTBA (in French)

McKenzie WM (1960) Fundamental aspects of the wood cutting process. For Prod J 10:447–456

McKenzie WM (1961) Fundamental aspects of the wood cutting process. PhD Thesis, University Michigan, Ann Arbor

McKenzie WM, Franz NC (1964) Inclined or oblique wood cutting. For Prod J 14:555–566

McKenzie WM, Cowling RL (1971a) A factorial experiment in transverse plane cutting of wood – Part I. Cutting force and edge wear. Wood Sci 3(4):204–213

McKenzie WM, Cowling RL (1971b) A factorial experiment in transverse plane (90/90) cutting of wood – Part II. Chip formation. Wood Sci 4(1):55–61

Mori M (1969) An analysis of cutting work in peripheral milling of wood. I On the work done by a knife in up-milling parallel to wood grain. Mokuzai Gakkaishi 15:93–98

Mori M (1970) An analysis of cutting work in peripheral milling of wood. II The cutting force, power and energy requirements in up-milling parallel to wood grain. Mokuzai Gakkaischi 16:1–9

Mori M (1971a) An analysis of cutting work in peripheral milling of wood. III Variation of cutting force in inside cutting of wood with router-bit. Mokuzai Gakkaishi 17:437–442

Mori M (1971b) An analysis of cutting work in peripheral milling of wood. IV The power requirements in inside cutting of wood with router-bit. Mokuzai Gakkaishi 17:443–448

Negri M, Goli G (2000) Quality of machined surfaces of Norway spruce and Douglas fir assessed by visual grading. Legno Cellul Carta 6(1):10–21 (in Italian)

Piao SY, Fukui H (1984) Specific cutting-force in the machining of wood I. Dependence on rake and clearance angles and effect of chip thickness. Mokuzai Gakkaishi 30:359–367

Santochi M, Giusti F (2000) Manufacturing technology and engineering. Casa Editrice Ambrosiana, Milano (in Italian)

Stewart HA (1971) Chip formation when orthogonally cutting wood against the grain. Wood Sci Technol 3(4):193–203

Stewart HA (1969) Effect of cutting direction with respect to grain angle on the quality of machined surface, tool force components, and cutting friction coefficient. For Prod J 19(3):43–46

Woodson GE, Koch P (1970) Tool forces and chip formation in orthogonal cutting of loblolly pine. Department of Agriculture-Forest Service research paper SO-52

Yoshihara H, Ohta M (2000) Estimation of the shear strength of wood by uniaxial-tension tests of off-axis specimens. J Wood Sci 46:159–163

Zompì A, Levi R (2003) Manufacturing technology. Chip removal processing. UTET Libreria, Torino (in Italian)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Goli, G., Fioravanti, M., Marchal, R. et al. Up-milling and down-milling wood with different grain orientations – theoretical background and general appearance of the chips . Eur. J. Wood Prod. 67, 257–263 (2009). https://doi.org/10.1007/s00107-009-0323-3

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-009-0323-3