Abstract

Cement bonded particleboards were manufactured from maple (Acer platanoides L.) wood particles. The results revealed that the mixture of maple-cement can be classified as moderate inhibition, as determined by the hydration tests. Two wood:cement ratios were applied in this study, namely 1:3 and 1:4, for the board manufacture. An increase in the cement-wood ratio resulted in an increase in all, but MOR values. Boards were exposed to brown and white rot fungi, Coniophora puteana, Trametes versicolor, respectively. Overall, both fungi failed to attack the cement-bonded boards.

Similar content being viewed by others

References

BISON (1978) Wood-Cement Board. Report, pp 1–65

DD ENV 12038 Wood Preservatives (1996) Determination of the toxic values against wood destroying Basidiomycetes cultured on an agar medium. British Standards Institution. EN 113 (1982)

De Souza MR, Geimer LR, Moslemi AA (1997) Degradation of conventional and CO2-injected cement-bonded particleboard by exposure to fungi and termites. J Trop For Prod 3:63–69

Dinwoodie JM, Paxton BH (1991) The long term performance of cement-bonded particleboard. In: Inorganic bonded wood and fiber materials. 2nd International Conference, Moscow, p 45

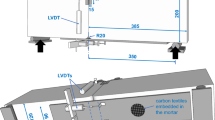

European Standard EN 310 (1993) Wood based panels-Determination of modulus of elasticity in bending and of bending strength. CEN European Committee for Standardisation

European Standard EN 319 (1993) Particleboards and fibreboards-Determination of tensile strength perpendicular to the plane of the board CEN European Committee for Standardisation

European Standard EN 317 (1993) Particleboards and fibreboards-Determination of swelling in thickness after immersion in water. CEN European Committee for Standardisation

Goodell B, Daniel G, Liu L, Mott L, Frank R (1997) Decay resistance and microscopic analysis of wood-cement composites. For Prod J 3:75–80

Jorge FC, Pereira C, Ferreira JMF (2004) Wood-cement composites: a review. Holz Roh- Werkst 62:370–377

Moslemi AA, Pfister SC (1987) The influence of cement-wood ratio and cement type on bending strength and dimensional stability of wood-cement composite panels. Wood Fiber Sci 19:165–175

Okino EYA, de Souza MR, Santana MAE, da Alves MV, de Souza ME, Texeira DE (2005) Physico-mechanical properties and decay resistance of Cupressus ssp. cement-bonded particleboards. Cement Concr Compos 27:333–338

Papadopoulos AN (2007) An investigation of the suitability of some Greek wood species in wood-cement composites manufacture. Holz Roh- Werkst 65(3):245–246

Papadopoulos AN, Ntalos GA, Kakaras I (2006) Mechanical and physical properties of cement-bonded OSB. Holz Roh- Werkst 64:517–518

Pirie BJ, Glasser FO, Schimitts H, Akers SAS (1990) Durability studies and characterisation of the matrix and fibre-cement interface of asbestos-free fibre-cement products. Cement Concr Compos 12:233–234

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Papadopoulos, A.N. Performance of cement bonded boards made from maple particles . Holz Roh Werkst 66, 385–387 (2008). https://doi.org/10.1007/s00107-008-0260-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-008-0260-6