Abstract

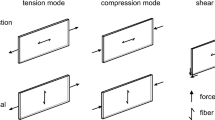

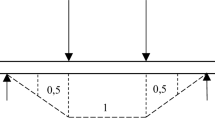

Bending and tensile tests were carried out on veneer of beech (Fagus sylvatica L.) and European oak (Quercus robur L./Quercus petraea Liebl.) with a thickness between 0.35 mm and 0.5 mm. The tests were done on veneer in two test series, one parallel to the fibre and the other one perpendicular to the fibre. Mechanical properties and bending radiuses were measured and evaluated. It could be concluded that the bending properties of the veneers not only depend on the bending stiffness but also the mechanical strength and structure of the material. During the tests it could be shown that the 3-point bending test procedure is not a suitable method for determining the bending modulus of rupture.

Zusammenfassung

Es wurden Biege- und Zugprüfungen an Furnieren der Holzarten Rotbuche (Fagus sylvatica L.) und Europäische Eiche (Quercus robur L./Quercus petraea Liebl.) durchgeführt. Die Versuche wurden jeweils parallel und senkrecht zur Faserrichtung an 0,35 mm und 0,5 mm dicken Furnieren durchgeführt. Mechanische Kennwerte sowie Biegeradien wurden ermittelt und bewertet. Es konnte geschlussfolgert werden, dass die Biegefähigkeit von Furnieren nicht ausschließlich von deren Biegesteifigkeit abhängt, sondern Festigkeit und Struktur des Materials ebenfalls entscheidenden Einfluss haben. Zur Ermittlung der Biegefestigkeit von Furnier erwies sich der 3-Punkt-Biegeversuch als nicht geeignet.

Similar content being viewed by others

References

Dyachun ZI (1974) Investigation of the minimum permissible radius of bending of veneer. Lesnoi Zhurnal 17(1):156–158 (in Russian)

Koloc K (1951) Werkstoff-Kartei Koloc Holz. Fachbuchverlag, Leipzig

Shupe TF, Hse CY, Choong ET, Groom LH (1997) Effects of silvicultural practice and moisture content level on loblolly pine veneer mechanical properties. For Prod J 47(11/12):92–96

Srinivasan N, Bhattacharyya D, Jayaraman K (2007) Thermoforming of wood veneer composites sheets. Holzforschung 61:558–562

Wagenführ R (2007) Holzatlas. Fachbuchverlag, Leipzig

Yanson AI, Dyachun ZI (1977) Determining the minimum permissible radius of bending of a set of plies. Lesnoi Zhurnal 3:74–78 (in Russian)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Buchelt, B., Wagenführ, A. The mechanical behaviour of veneer subjected to bending and tensile loads . Holz Roh Werkst 66, 289–294 (2008). https://doi.org/10.1007/s00107-008-0235-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-008-0235-7