Abstract

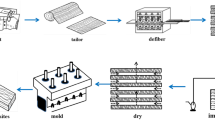

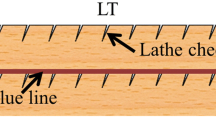

Cross-linked polyvinyl acetate (PVAc) adhesive and thin veneers of three low density wood species, namely silver maple, yellow poplar and aspen, were used to produce LVL engineered wood products using different press durations. Density, water absorption, thickness swelling, flexural strength and surface hardness were evaluated. Internal bond strength, tensile shear and block shear strengths were tested in dry, accelerated (boiling and dry) and cyclic (wet and dry) conditions. LVL made using cross-linked polyvinyl acetate and silver maple with a platen temperature of 38 °C for 5 minutes exhibited the best properties. LVL of silver maple veneers showed improved properties as compared to yellow poplar and aspen. Silver maple can be used suitably in laminated veneer flooring.

Zusammenfassung

Aus vernetztem Polyvinylacetat (PVAc) und dünnen Furnieren dreier Holzarten von geringer Dichte, Silberahorn, Amerikanischem Tulpenbaum und Espe, wurden unter Verwendung von unterschiedlichen Presszeiten Furnierschichtholzprodukte hergestellt. Dichte, Wasserabsorption, Dickenquellung, Biegefestigkeit und Oberflächenhärte wurden bestimmt. Querzugfestigkeit, Zugscher- sowie Blockscherfestigkeit wurden unter trockenen Bedingungen sowie nach schneller Bewitterung (kochen und trocknen) sowie zyklischer klimatischer Beanspruchung (nass und trocken) geprüft. Dabei wies Furnierschichtholz aus vernetztem Polyvinylacetat und Silberahorn bei einer Presstemperatur von 38 °C und einer Pressdauer von 5 Minuten die besten Eigenschaften auf. LVL aus Silberahorn könnte beispielsweise gut als Bodenbelag aus Furnierschichtholz eingesetzt werden.

Similar content being viewed by others

References

American Society for Testing and Materials (1999) ASTM D 1037, Standard test method for evaluating properties of wood base fibre and particle panel materials. ASTM, West Conshohocken, PA

American Society for Testing and Materials (2004) ASTM D 906-98 (Reapproved in 2004), Standard test method for strength properties of adhesives in plywood type construction in shear by tension loading. ASTM, West Conshohocken, PA

American Society for Testing and Materials (2006) ASTM D 5456-06, Standard specification for evaluation of structural composite lumber products. ASTM, West Conshohocken, PA

Anon (2001) Wood Handbook: Wood as an Engineering Material. Forest Product Laboratory, General Technical Report FPL-GTR-113, U.S. Department of Agriculture, pp 4–5 (Pp 751)

Alamsyah EM, Nan LC, Yamada M, Taki K, Yoshida H (2007) Bondability of tropical fast-growing tree species I: Indonesian wood species. J Wood Sci 53:40–46

Blanchet P, Beauregard R, Erb A, Lefebvre M (2003) Comparative study of four adhesives used as binder in engineered wood parquet flooring. Forest Prod J 53(1):89–93

Blanchet P, Gendron G, Cloutier A, Beauregard R (2005) Numerical prediction of engineered wood flooring deformation. Wood Fiber Sci 37(3):484–496

Blanchet P, Cloutier A, Gendron G, Beauregard R (2006) Engineered wood flooring design using the finite element method. Forest Prod J 56(5):59–65

Burdurlu E, Kilic Y, Elibol GC, Kilic M (2006) Shear strength of calabrian pine (Pinus brutia Ten.) bonded with polyurethane and polyvinyl acetate adhesives. J Appl Polym Sci 100:4856–4867

Eckelman CA (1993) Potential uses of laminated veneer lumber in furniture. Forest Prod J 43(4):19–24

Feng F, Bao FC, Fu F, Bao FC (1999) End use selection of plantation poplar: solid wood or laminated veneer lumber (LVL). Sci Silvae Sinicae 35(4):58–65

Fridley KJ (2002) Wood and wood-based materials: current status and future of structural material. J Mater Civil Eng 14(2):91–96

Hayashi T, Oshiumi S (1993) Bending strength distribution of laminated veneer lumber for structural use. Mokuzai Gakkaishi J Japan Wood Res Soc 39(9):985–992

Hesterman ND, Gorman TM (1992) Mechanical properties of laminated veneer lumber made from interior Douglas fir and lodge pole pine. Forest Prod J 42(11/12):69–73

Hsu WE (1988) Laminated veneer lumber from aspen. Proc. of the 22nd International Particleboard/Composite Material Symposium, Washington State University, pp 257–269

Kilic Y, Colak M, Baysal E, Burdurlu E (2006) An investigation of some physical an mechanical properties of laminated veneer lumber manufactured from black alder (Alnus glutinosa) glued with polyvinyl acetate and polyurethane adhesives. Forest Prod J 56(9):56–59

Kim S, Kim H-J (2006) Study of miscibility of melamine-formaldehyde resin and poly (vinyl acetate) blends for use as adhesives in engineered flooring. J Adhesion Sci Technol 20(2–3):209–219

Lam F (2001) Modern structural wood products. Prog Struct Eng Mater 3:238–245

Lee JN, Tang RC, Kaiserlik JH (1999) Edgewise static bending properties of yellow-poplar laminated veneer lumber: effect of veneer-joint designs. Forest Prod J 49(7/8):64–70

Luzadis VA, Gossett ER (1996) Sugar Maple. Pp 157–166. Forest Trees of the Northeast. Lassoie JP, Luzadis VA, Grover DW (eds) Cooperative Extension Bulletin 235. The Resource Center Cornell University, Ithaca, NY (available at the website: http://maple.dnr.cornell.edu/pubs/trees.htm)

Ozarska B (1999) A review of the utilisation of hardwoods for LVL. Wood Sci Technol 33:341–351 (Durand-Raute Industries Ltd (1988) Laminated Veneer Lumber from aspen veneer. Company Report. 8 pages)

Qiao L, Easteal AJ, Bolt CJ, Coveny PK, Franich RA (2000a) Improvement of the water resistance of poly(vinyl acetate) emulsion wood adhesive. Pigm Resin Technol 29(3):152–158

Qiao L, Easteal AJ, Bolt CJ, Coveny PK, Franich RA (2000b) Thermomechanical analysis and performance tests of some EPI wood adhesives. Pigm Resin Technol 29(4):229–237

Qiao L, Coveny PK, Easteal AJ (2002) Modifications of poly(vinyl alcohol) for use in poly(vinyl acetate) emulsion wood adhesive. Pigm Resin Technol 31(2):88–95

Schuler A, Adair C (2003) Engineered and Other Wood Products – An Opportunity to “Grow the Pie”. In: 37th international wood composite materials symposium, pp 43–53

Sellers T Jr, McSween JR, Nearn WT (1988) Gluing of eastern hardwoods: a review. Gen Techn Rep SO–71. New Orleans, LA: U.S. Department of Agriculture, Forest Service, Southern Forest Experimental Station, p 30

Sellers T Jr (2001) Wood adhesive innovations and applications in North America. Forest Prod J 51(6):12–22

Umemura K, Inoue A, Kawai S (2003) Development of new natural polymer-based wood adhesives I: dry bond strength and water resistance of konjac glucomannan, chitosan, and their composites. J Wood Sci 49:221–226

Wang BJ, Dai C (2005) Hot-pressing stress graded aspen veneer for laminated veneer lumber (LVL). Holzforschung 59:10–17

Wong ED, Razali AK, Kawai S, Wong ED (1996) Properties of rubber wood LVL reinforced with Acacia veneers. Wood Research (83):8–16

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shukla, S.R., Kamdem, D.P. Properties of laminated veneer lumber (LVL) made with low density hardwood species: effect of the pressure duration . Holz Roh Werkst 66, 119–127 (2008). https://doi.org/10.1007/s00107-007-0209-1

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-007-0209-1