Abstract

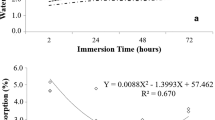

Wood composite industry has focused on traditional wood fibre resources such as logs, wood chips and sawmill-residues for panel manufacturing. It is becoming necessary now for the wood composite panel industry to look for ways to utilize non-traditional forest resources such as forest residuals for panel manufacturing. A full factorial experimental design with two factors: retention time of preheating and steam pressure of thermal mechanical refining and three levels with 3, 5, 7 minutes of retention time and 6, 9, 12 bar of steam pressure was carried out in the MDF pilot plant of Forintek Canada Corp. in Quebec City of Canada to evaluate the effect of refining conditions on the properties of MDF panels made from the tops of black spruce (Picea mariana). The results from this study indicate that black spruce tops could be a good raw material for MDF manufacture. The effects of steam pressure of thermomechanical refining on modulus of elasticity (MOE), thickness swelling (TS), water absorption (WA) and linear expansion (LE) were considerable. The effect of retention time of preheating on internal bond strength (IB) was significant. The effects of retention time as well as the interaction between retention time and steam pressure were also significant for modulus of rupture (MOR).

Zusammenfassung

Bisher wurden in der Holzwerkstoffindustrie zur Plattenherstellung vorwiegend herkömmliches Industrieholz, Hackschnitzel und Sägerestholz verwendet. Mittlerweile muss die Holzwerkstoffindustrie nach Wegen suchen, bisher traditionell nicht genutzte Ressourcen, wie zum Beispiel Gipfelstücke, für die Plattenherstellung einzusetzen. Zur Untersuchung des Einflusses der Aufschlussbedingungen auf die Eigenschaften von MDF-Platten aus Schwarzfichten-Gipfelholz (Picea mariana) wurde ein voll-faktorieller Versuch mit zwei Variablen (Aufheizdauer sowie Dampfdruck im Refiner) und jeweils drei Stufen (Aufheizdauer: 3, 5 und 7 Minuten, Dampfdruck: 6, 9 und 12 Bar) in der MDF-Versuchsanlage von Forintek Canada Corp. in Quebec durchgeführt. Die Ergebnisse dieser Studie zeigen, dass Schwarzfichten-Gipfelholz als Rohmaterial für die MDF-Herstellung grundsätzlich geeignet ist. Der Dampfdruck beim thermomechanischen Refinerverfahren hatte großen Einfluss auf den E-Modul (MOE), die Dickenquellung (TS), die Wasseraufnahme (WA) und die Längenausdehnung (LE). Die Aufheizdauer hatte signifikanten Einfluss auf die Querzugfestigkeit (IB). Die Aufheizdauer sowie die Wechselwirkung zwischen Aufheizdauer und Dampfdruck wirkten sich signifikant auf die Biegefestigkeit (MOR) aus.

Similar content being viewed by others

References

American National Standards Institute (ANSI) (2002) Medium Density Fibreboard (MDF) for Interior Application. ANSI A208.2-2002. Composite Panel Association, Gaithersburg, MD

American Society of Testing and Materials (ASTM) (2001) Evaluating properties of wood-based fibre and particle panel materials. ASTM D 1037--2001. ASTM, Philadelphia, PA

Chockie AD (1982) Pacific northwest biomass as an energy resource. Altern Energy Source 4(4):19--26

Deppe HJ (1991) Renewable materials: wood and wood-based materials. J Mater Prod Technol 6(1):63--67

Feldmann HF (1978) Conversion of forest residues to a methane-rich gas. In: Proc -- Annu Fuels Biomass Symp, 2nd, vol. 1, pp 245--251

Feldmann HF, Liu KT, Longanbach JR, Curran LM, Chauhan SP (1979) Conversion of forest residues to a clean gas for fuel or synthesis. Eng Conf Proc 1:81--89

Forsberg G (2000) Biomass energy transport analysis of bioenergy transport chains using life cycle inventory method. Biomass Bioenerg 19(1):17--30

Galbe M, Zacchi G (2002) A review of the production of ethanol from softwood. Appl Microbiol Biotechnol 59(6):618--628

Groom LH, So CL, Elder T, Pesacreta T, Rials T (2004) Effect of refining pressure and resin viscosity and resin flow, distribution, and penetration of MDF fibers. In: The 7th Pacific Rim Bio-Based Composites Symposium, vol. 1, pp 227--239

Kehr E, Drechsler W (1978) Smallwood: An important raw material for fiberboard and particleboard production. Holztechnologie 19(2):67--74

Kelley SS, Elder T, Groom LH (2005) Changes in the chemical composition and spectroscopy of loblolly pine medium density fiberboard furnish as a function of age and refining pressure. Wood Fiber Sci 37(1):14--22

Krug D, Kehr E (2001) Influence of high pulping pressures on permanent swelling-tempered medium density fibreboards. Holz Roh- Werkst 59(5):342--343

Maloney TM (1993) In: Miller Freeman (ed) Modern particleboard and dry-process fiberboard manufacturing. San Francisco, CA

Nunez-Regueira L, Rodriguez-Anon J, Proupin J, Romero-Garcia A (2003) Energy evaluation of forest residues originated from pine in Galicia. Bioresource Technol 88(2):121--130

Peter JJ, Bender DA, Wolcott MP, Johnson JD (2002) Selected properties of hybrid poplar clear wood and composite panels. For Prod J 52(5):45--54

Roffael E, Dix B, Schneider T (2001) Thermomechanical (TMP) and Chemo-Thermomechanical Pulps (CTMP) for Medium Density Fibreboard (MDF). Holzforschung 55(2):214--218

Shi JL, Zhang SY, Riedl B (2005) Effect of Juvenile Wood on Strength Properties and Dimensional Stability of Black Spruce Medium Density Fiberboard Panels. Holzforschung 59:1--9

Spano LA (1977) Enzymic hydrolysis of cellulosic materials. Proc Semin, pp 157--177

Walt D (2003) Development of biobased products. Appl Biochem Biotechnol 107(1--3):635--636

Xing C, Riedl B, Cloutier A, Deng J, Zhang SY (2005) UF Resin Efficiency of MDF as Affected by Resin Content loss, coverage level and pre-cure. Holz Roh- Werkst 64(3):221--226

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xing, C., Deng, J., Zhang, S.Y. et al. Properties of MDF from black spruce tops as affected by thermomechanical refining conditions . Holz Roh Werkst 64, 507–512 (2006). https://doi.org/10.1007/s00107-006-0129-5

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-006-0129-5