Abstract

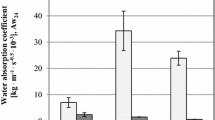

Heat-treatment changes the chemical and physical properties of wood. Wood polymers are degraded, dimensional stability is enhanced, equilibrium moisture content is lowered, colour darkens and biological durability is increased. The properties of heat-treated wood have been researched considerably, but the differences between sapwood and heartwood have not been reported separately. In this research, water absorption differences between sapwood and heartwood of Scots pine and Norway spruce heat-treated at temperatures 170 °C, 190 °C, 210 °C and 230 °C were investigated. The results were compared to industrially kiln-dried reference samples. Water absorption was determined with a floating test based on the EN 927-5 standard. The heartwood of both wood species absorbed less water than sapwood. Heat-treatment evidently decreased the water absorption of spruce and pine heartwood. The higher the heat-treating temperature, the lower the amount of absorbed moisture. However, a very interesting exception was pine sapwood, whose water absorption actually increased with heat-treatment after the three lowest heat-treatment temperatures compared to the reference material. Water absorption did not decrease until the heat-treatment temperature was 230 °C.

Zusammenfassung

Durch Wärmebehandlung werden sowohl die chemischen als auch physikalischen Eigenschaften von Holz verändert. Holzpolymere werden abgebaut, Dimensionsstabilität verbessert, Gleichgewichtsfeuchte verringert, Holz verfärbt sich dunkel und die biologische Dauerhaftigkeit wird erhöht. Die Eigenschaften von wärmebehandeltem Holz wurden zwar umfangreich untersucht, jedoch die Unterschiede zwischen Splint- und Kernholz nicht gesondert dargestellt. In der vorliegenden Studie wurde die unterschiedliche Wasseraufnahme von Splint- und Kernholz von Fichte und Kiefer untersucht, die bei Temperaturen von 170 °C, 190 °C, 210 °C und 230 °C wärmebehandelt wurden. Die Ergebnisse wurden mit technisch getrockneten Proben verglichen. Die Wasseraufnahme wurde mit einer Prüfung nach EN 927-5 bestimmt. Das Kernholz beider Holzarten nahm weniger Wasser auf als das Splintholz. Eine Wärmebehandlung reduzierte ganz offensichtlich die Wasseraufnahme bei Fichten- und Kiefernkernholz. Je höher die Temperatur, desto geringer war die Wasseraufnahme. Allerdings stellt Kiefernsplintholz eine interessante Ausnahme dar, da hier die Wasseraufnahme nach Wärmebehandlung bei den drei ersten Temperaturen gegenüber den Vergleichsproben zunahm. Die Wasseraufnahme nahm erst bei einer Behandlungstemperatur von 230 °C ab.

Similar content being viewed by others

References

Alén R, Kotilainen R, Zaman A (2002) Thermochemical behavior of Norway spruce (Picea abies) at 180–225 °C. Wood Sci Technol 36:163–171

Bekhta P, Niemz P (2003) Effect of High Temperature on the Change in Color, Dimensional Stability and Mechanical Properties of Spruce Wood. Holzforschung 57:539–546

Chanrion P, Schreiber J (2003) Heat Treated Timber. Editions CTBA, Paris

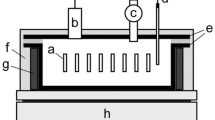

EN 927-5 standard (2000) Paints and varnishes – Coating materials and coating systems for exterior wood – Part 5: Assessment of the liquid water permeability. European Committee for Standardization, Brussels

Hakkou M, Pétrissans M, El Bakali I, Gérardin P, Zoulalian A (2005) Wettability changes and mass loss during heat treatment of wood. Holzforschung 59:35–37

Hakkou M, Pétrissans M, Zoulalian A, Gérardin P (2005) Investigation of wood wettability changes during heat treatment on the basis of chemical analysis. Polym Degrad Stabil 89:1–5

Jämsä S, Ahola P, Viitaniemi P (1999) Performance of coated heat-treated wood. Surf Coat Int 6:297–300

Jämsä S, Ahola P, Viitaniemi P (2000) Long-term natural weathering of coated ThermoWood. Pigm Resin Technol 29:68–74

Kamdem DP, Pizzi A, Jermannaud A (2002) Durability of heat-treated wood. Holz Roh- Werkst 60:1–6

Kollmann F, Côté W (1968) Principles of Wood Science and Technology – Solid Wood. Springer, Berlin

Kärkkäinen M (2003) Puutieteen perusteet (Principles of Wood Science). Karisto Oy, Hämeenlinna. In Finnish

Milton JS, Arnold JC (1995) Introduction to Probability and Statistics – Principles and Applications for Engineering and the Computing Sciences. McGraw-Hill, Singapore

Montgomery DC, Peck EA (1992) Introduction to Linear Regression Analysis. John Wiley, New York

Pétrissans M, Gérardin P, El Bakali I, Serraj M (2003) Wettability of Heat-Treated Wood. Holzforschung 57:301–307

Rapp AO (ed) (2001) Review of heat treatments of wood. Proceedings of COST E22 WG3. Special Seminar on Heat Treatments on 9 February 2001

Repellin V, Guyonnet R (2005) Evaluation of heat-treated wood swelling by differential scanning calorimetry in relation to chemical composition. Holzforschung 59:28–34

Sailer M, Rapp AO, Leithoff H, Peek RD (2000) Vergütung von Holz durch Anwendung einer Öl-Hitzebehandlung. Holz Roh- Werkst 58:15–22

Santos JA (2000) Mechanical behaviour of Eucalyptus wood modified by heat. Wood Sci Technol 34:39–43

Sivonen H, Maunu SL, Sundholm F, Jämsä S, Viitaniemi P (2002) Magnetic Resonance Studies of Thermally Modified Wood. Holzforschung 56:648–654

Viitaniemi P, Jämsä S (1996) Puun modifiointi lämpökäsittelyllä (Modification of wood with heat treatment). VTT Publications 814, Espoo. In Finnish, English abstract

Viitaniemi P (1997a) Thermowood – Modified Wood for Improved Performance. In: Proceedings of the 4th Eurowood Symposium ‘Wood – The Ecological Material’, Stockholm, Sweden. Trätek Rapport No. P9709084:67–69

Viitaniemi P (1997b) Decay-resistant wood created in a heating process – A heat-treatment process of wood developed by VTT Building Technology yields timber products with enhanced properties. Indust Horizons December:22–23

Viitaniemi P (2000) New properties for thermally-treated wood. Indust Horizons March:9

Viitaniemi P, Jämsä S, Ek P, Viitanen H (2001) Pat. EP-695408B1. Method for increasing the resistance of cellulosic products against mould and decay. Appl. 94915166.6, 13.5.1994. Publ. 10.1.2001

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Metsä-Kortelainen, S., Antikainen, T. & Viitaniemi, P. The water absorption of sapwood and heartwood of Scots pine and Norway spruce heat-treated at 170 °C, 190 °C, 210 °C and 230 °C. Holz Roh Werkst 64, 192–197 (2006). https://doi.org/10.1007/s00107-005-0063-y

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-005-0063-y