Abstract

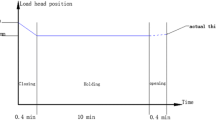

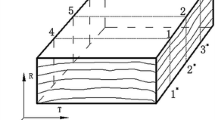

The effects of grain orientation and surface wetting on wood densification by compression in a hot press were evaluated for two commercial Canadian wood species, balsam fir (Abies balsamea) and black spruce Picea mariana. The vertical density profiles (VDP) of wood densified at 180 °C could be engineered to achieve different properties depending on press closing rate, wood permeability and annual ring orientation. The lower permeability of spruce caused it to split frequently during hot pressing. For balsam fir, at a press closing time of 2 min, the compressed wood with an original grain angle of 0° (radial compression) shows widened high density bands due to collapse of low density earlywood adjacent to the dense latewood. All grain orientations show higher density areas close to the wood surfaces similar to those of wood-based composites. However, when wood was preheated without pressure for 5 min followed by a press closing time of 2 min, water migrated to and plasticized the board centre causing it to be densified while the surface density remained low. Wood surface plasticizing with water or urea solution causes some localized surface densification, but the effect was not great.

Zusammenfassung

An zwei kanadischen Nutzhölzern, Balsam fir (Abies balsamea) und Black spruce ( Picea mariana) wurde untersucht, wie sich die Jahrringstellung und eine Oberflächenbefeuchtung auf die Verdichtung dieser Hölzer in einer Heisspresse auswirkt. Über die Querschnittshöhe kann ein unterschiedliches Rohdichteprofil erzeugt werden. In Abhängigkeit der Presszeit, der Permeabilität und der Jahrringstellung der Hölzer konnten bei einer Verdichtung bei 180 °C unterschiedliche Dichteprofile (VDP) erzeugt werden. Die geringe Permeabilität von Fichtenholz führte während des Heisspressens häufig zum Aufspalten. Bei Tannenholz, das mit einer Presszeit von 2 min. und einer Jahrringstellung von 0 °C (Druck in radialer Richtung) verdichtet wurde, bildeten sich durch den Kollaps des an Spätholz angrenzenden Frühholzes verbreiterte Bereiche hoher Dichte. Bei allen Jahrringstellungen bildete sich wie bei plattenförmigen Holzwerkstoffen ein Rohdichteprofil mit erhöhter Dichte an den Oberflächen aus. Wenn das Holz jedoch 5 min. lang ohne Druck vorgeheizt und dann bei einer Presszeit von 2 min. verdichtet wurde, diffundierte das Wasser nach innen. Der innere Bereich des Holzes plastifizierte und verdichtete sich dadurch, während sich die oberflächennahen Schichten weniger stark verdichteten. Eine Plastifizierung der Holzoberflächen mit Wasser oder Harnstofflösung ergab eine örtlich begrenzte, nicht stark ausgeprägte Oberflächenverdichtung.

Similar content being viewed by others

References

Bodig J (1963) The peculiarity of compression of conifers in radial direction. Forest Prod J 13:438

Bodig J (1965a) The effect of anatomy on the initial stress-strain relationship in transverse compression. Forest Prod J 15(5):197–202

Bodig J (1965b) Effect of growth characteristics on the mechanical properties of Douglas-fir in radial compression. Holzforschung 19(3):83–88

Bodig J (1966) Stress-strain relationship for wood in transverse compression. J Mater 1(3):645–666

Bodig J, Jayne BA (1982) Mechanics of Wood and Wood Composites. Van Nostrand Reinhold Company, New York, America

Currier RA (1963) Compressibility and bond quality of western softwood veneers. Forest Prod J 13:71–80

Dai C, Steiner PR (1993) Compression behavior of randomly formed wood flake mats. Wood Fiber Sci 25(4):349–358

Dwianto W, Morooka T, Norimoto M (1998) The compressive stress relaxation of Albizia (Paraserienthes falcata Becker) wood during heat treatment (in Japanese with English abstract). Mokuzai Gakkaishi 44(6):403–409

Dwianto W, Morooka T, Norimoto M, Kitajima T (1999) Stress relaxation of sugi (Cryptomeria japonica D. Don) wood in radial compression under high temperature steam. Holzforschung 53:541–546

Dwianto W (1999) Mechanism of permanent fixation of radial compressive deformation of wood by heat or steam treatment [Dissertation]. Japan Wood Research Institute, Kyoto University, Kyoto

Inoue M, Norimoto M, Otsuka Y, Yamada T (1990) Surface compression of coniferous wood lumber.. A new technique to compress the surface layer. Mokuzai Gakkaishi 36(11):969–975

Inoue M, Norimoto M, Tanahashi M, Rowell RM (1993a) Steam or heat fixation of compressed wood. Wood Fiber Sci 25(3):224–235

Inoue M, Ogata S, Kawai S, Rowell RM, Norimoto M (1993b) Fixation of compressed wood using melamine-formaldehyde resin. Wood Fiber Sci 25(4):404–410

Inoue M (1993) Transverse compression deformation of wood and its permanent fixation [Dissertation]. Japan Wood Research Institute, Kyoto University, Kyoto

Inoue M, Minato K, Norimoto M (1994) Permanent fixation of compressive deformation of wood by crosslinking. Mokuzai Gakkaishi 40(9):931–936

Kamke FA, Casey LJ (1988) Fundamentals of flakeboard manufacture: internal-mat conditions. Forest Prod J 38(6):38–44

Kennedy RW (1968) Wood in transverse compression-Influence of some anatomical variables and density on behavior. Forest Prod J 18(3):36–40

King EG (1961) Time-dependent strain behavior of wood in tension parallel to the grain. Forest Prod J 11:156–165

Kunesh RH (1961) The inelastic behavior of wood: A new concept for improved panel forming processes. Forest Prod J 11:395–406

Lenth CA, Kamke FA (1996) Investigations of flakeboard mat consolidation / characterization the cellular structure. Wood Fiber Sci 28(2):159–167

Liu YX, Norimoto M, Morooka T (1993) The large compressive deformation of wood in the transverse direction 1: Relationships between stress-strain diagrams and specific gravities of wood. Mokuzai Gakkaishi 39(10):1140–1145

Norimoto M (1993) Large compressive deformation in wood (in Japanese). Mokuzai Gakkaishi 39(8):867–874

Norimoto M (1994) Heat treatment and steam treatment of wood (in Japanese). Wood Ind 49(12):588–592

Schniewind AP (1959) Transverse anisotropy of wood: A function of gross anatomic structure. Forest Prod J 9:350–359

Seborg RM, Millett MA, Stamm AJ (1945) Heat-stabilized compressed wood-(Staypak). Mech Eng 67:25–31

Shamaev VA, El’kov LV, Popova NI (1975) Stabilization of wood modified with urea (in Russian). Izv VUZ, Lesnoi Zh 18(5):97–101

Stamm AJ, Harris EE (1953) Chemical processing of wood. Chemical Publishing Co, Inc, New York, America, pp 205–261

Stamm AJ (1964) Wood and Cellulose Science. Ronald Press, New York, pp 317–358

Strickler MD (1959) Effect of press cycle and moisture content on properties of Douglas-fir flakeboard. Forest Prod J 9(7):203–215

Tabarsa T, Chui YH (1997) Effects of hot-pressing on properties of white spruce. Forest Prod J 47(5):71–76

Tabarsa T, Chui YH (2000) Stress-strain response of wood under radial compression. Test method and influence of cellular properties. Wood Fiber Sci 32(2):144–152

Tabarsa T, Chui YH (2001) Characterizing microscope behavior of wood under transverse compression. Effect of species and loading direction. Wood Fiber Sci 33(2):223–232

Wang JY, Zhao GJ (1999) The mechanism of formation, recovery and permanent fixation of wood set (in Chinese with English abstract). J Beijing For Univ 21(3):71–77

Wang JY, Zhao GJ, Iida I (2000) Effect of oxidation on heat fixation of compressed wood of China fir. For Stud China 2(1):73–79

Wang JY (2000) Fixation of compressed wood of Chinese fir by heat treatment and gamma irradiation [Dissertation]. Beijing Forestry University, China

Wang JY, Zhao GJ (2001) Fixation and creep of compressed wood of Chinese fir irradiated with gamma rays. For Stud China 3(1):58–65

Wang S, Winistorfer PM (2000) Fundamentals of vertical density profile formation in wood composites. Part 2. Methodology of vertical density formation under dynamic conditions. Wood Fiber Sci 32(2):220–238

Winistorfer PM, Young TM, Walker E (1996) Modeling and comparing vertical density profiles. Wood Fiber Sci 28(1):133–141

Winistorfer PM, Moschler WW, Wang S, Depaula E, Bledsoe BL (2000) Fundamentals of vertical density profile formation in wood composites. Part 1. In-situ density measurement of the consolidation process. Wood Fiber Sci 32(2):209–219

Wolcott MP, Kamke FA, Dillard DA (1990) Fundamentals of flakeboard manufacture: Viscoelastic behavior of the wood components. Wood Fiber Sci 22(4):345–361

Wong ED, Zhang M, Wang Q, Kawai S (1999) Formation of the density profile and its effects on the properties of particleboard. Wood Fiber Sci 33(2):327–340

Youngs RL (1957) Mechanical properties of red oak related to drying. Forest Prod J 7:315–324

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, J., Cooper, P. Effect of grain orientation and surface wetting on vertical density profiles of thermally compressed fir and spruce. Holz Roh Werkst 63, 397–402 (2005). https://doi.org/10.1007/s00107-005-0034-3

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-005-0034-3