Abstract

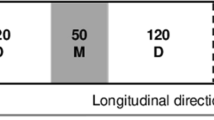

Collecting detailed drying curves for the drying of timber boards can be a laborious task. Consequently, drying curve data from which to base empirical drying models, or with which to evaluate more complicated models, is sparse for some forested species and for some drying conditions. This paper describes a robotic system that was developed to automatically measure individual board weights—and hence moisture contents—of boards stacked in a matrix formation in a simulated kiln environment. The system was designed to address a lack of data on the drying of Pinus radiata in dehumidifier conditions. However, the equipment design is relevant to the drying of any timber species, and is easily extended to other drying methods. Details of the system are presented, along with examples of output data.

Zusammenfassung

Detaillierte Trocknungskurven für das Trocknen von Schnittholz aufzunehmen, kann eine aufwendige Arbeit sein. Deswegen sind Daten von Trocknungskurven, von denen man empirische Modelle ableiten, oder mit denen man kompliziertere Modelle bewerten kann, nur spärlich für einige kommerzielle Holzarten oder für einige Trocknungsbedingungen vorhanden. Diese Arbeit beschreibt ein Robotersystem, das dazu entwickelt wurde, automatisch das Gewicht einzelner Bretter—und damit auch deren Feuchte—im Trocknungsstapel einer simulierten Trocknungsumgebung zu messen. Das System war dazu bestimmt, einem Mangel an Daten zum Trocknen von P. radiata in entwässernder Umgebung abzuhelfen. Die Versuchseinrichtung ist jedoch zum Trocknen jeder Holzart geeignet und kann leicht für andere Trocknungsmethoden angepasst werden. Einzelheiten dieses Systems werden vorgestellt zusammen mit beispielhaften Ergebnissen.

Similar content being viewed by others

References

Carrington CG, Liu Q (1995) Calorimeter measurements of a heat pump dehumidifier: influence of evaporator air flow. J Energy Res 19:649–658

Davis CP (2001) Drying Pinus Radiata boards in dehumidifier conditions. PhD Thesis, University of Otago, NZ

Davis CP, Carrington CG, Sun ZF (2001) Drying rate curves for the dehumidifier drying of Pinus Radiata boards. In: Proc 7th Int IUFRO Wood Drying Conf, pp 216–221

Davis CP, Carrington CG, Sun ZF (2002) The influence of compression wood on the drying curves of Pinus radiata dried in dehumidifier conditions. Drying Technol 20(10):2005–2026

Keey RB (1992) Drying of loose and particulate materials. Hemisphere

Keey RB, Walker JCF (1988) The drying of impermeable timbers: New Zealand Hard Beech. CHEMECA ‘88 Australia’s Bicentennial Conference for the Process Industries, pp 431–435

Morén T, Sehstedt PM (1999) Heat and mass transfer during sapwood drying above the FSP: consequences for kiln drying. In: Proc 6th Int IUFRO Wood Drying Conf, pp 205–211

Stanish MA, Schajer GS, Kayihan F (1986) A mathematical model of drying for hygroscopic porous media. AIChE J 32(8):1301–1311

Sun Z, Carrington G, McKenzie C, Bannister P, Bansal B (1996) Determination and application of characteristic drying-rate curves in dehumidifier wood drying. In: Proc 5th Int IUFRO Wood Drying Conf, pp 495–503

Zeleniuc O, Ene N (1996) Gravimetric system to determine the moisture content of wood during the drying process. In: Proc 5th Int IUFRO Wood Drying Conf, pp 213–220

Acknowledgements

The author wishes to acknowledge the financial support of the New Zealand Foundation for Research Science and Technology under PGSF contract UOOX0004. The assistance of G. Carrington, D. Hardisty, P.Stroud, and G. Vaughan is also gratefully acknowledged. The author is also grateful to the University of Otago for a Postgraduate Scholarship.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Davis, C.P. A robotic gravimetric test system for wood drying research. Holz Roh Werkst 62, 197–202 (2004). https://doi.org/10.1007/s00107-004-0486-x

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-004-0486-x