Abstract

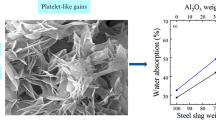

Closed-pore Al2O3-MgAl2O4 refractory aggregates have been prepared successfully based on the superplasticity of Al2O3 ceramic by using a mixed ball-milling method and the gelcasting method. The effects of SiC content on phase composition, porosity and microstructures of the refractory aggregates have been investigated. The properties of Al2O3-MgAl2O4 refractory aggregates fabricated by different methods have been compared to our results. We discuss the influence mechanism of SiC on the refractory aggregate. The results showed that the main phase compositions were corundum and MgAl2O4 spinel with accompanying small amounts of mullite phase. The closed porosity increased with increased addition of SiC. SiC facilitated the sinterability of materials resulting in a low level of apparent porosity. When compared to the mixed ball-milling method, the closed pore size distribution in the refractory aggregates fabricated by the gelcasting method was more uniform.

Similar content being viewed by others

References

Berjonneau, J., Prigent, P., Poirier, J.: The development of a thermodynamic model for Al2O3-MgO refractory castable corrosion by secondary metallurgy steel ladle slags. Ceram. Int. 35 (2009) 623–635

Yan, W., Li, N., Han, B.: Influence of microsilica content on the slag resistance of castables containing porous corundum-spinel aggregates. Int. J. Appl. Ceram. Technol. 5 (2008) 633–640

Yan, W., Chen, J., Li, N., Qiu, W., Wei, Y., Han, B.: Preparation and characterization of porous MgO-Al2O3 refractory aggregates using an in-situ decomposition pore-forming technique. Ceram. Int. 41 (2015) 515–520

Gregorová, E., Pabst, W.: Porous ceramics prepared using poppy seed as a pore-forming agent. Ceram. Int. 33 (2007) 1385–1388

Bai, J., Wei, C., Meng, F., Liu, J., Wang, P., Du, Q., Tang, Z.: Fabrication of porous Al2O3-MgAl2O4 ceramics using combustion-synthesized powders containing in situ produced pore-forming agents. Mater. Lett. 65 (2011) 1559–1561

Yan, W., Li, N., Han, B.: Preparation and characterization of porous ceramics prepared from kaolinite gangue and Al(OH)3 with double addition of MgCO3 and CaCO3. Int. J. Miner. Metall. Mater. 18 (2011) 450–454

Li, S., Li, N.: Effects of composition and temperature on porosity and pore size distribution of porous ceramics prepared from Al(OH)3 and kaolinite gangue. Ceram. Int. 33 (2007) 551–556

Salomão, R., Bôas, M.V., Pandolfelli, V.C.: Porous alumina-spinel ceramics for high temperature applications. Ceram. Int. 37 (2011) 1393–1399

Deng, Z., Fukasawa, T., Ando, M.: Microstructure and mechanical properties of porous alumina ceramics fabricated by the decomposition of hydroxide. J. Am. Ceram. Soc. 84 (2001) 2638–2644

She, J., Ohji, T.: Fabrication and characterization of highly porous mullite ceramics. Mater. Chem. Phys. 80 (2003) 610–614

She, J., Yang, J., Jayaseelan, D.D., Kondo, N., Ohji, T., Kanzaki, S., Inagaki, Y.: Thermal shock behavior of isotropic and anisotropic porous silicon nitride. J. Am. Ceram. Soc. 86 (2003) 738–740

Kishimoto, A., Obata, M., Asaoka, H., Hayashi, H.: Fabrication of alumina-based ceramic foams utilizing superplasticity. J. Europ. Ceram. Soc. 27 (2007) 41–45

Mao, X.J., Shimai, S., Dong, M.J., Wang, S.W.: Gelcasting of alumina using epoxy resin as a gelling agent. J. Am. Ceram. Soc. 90 (2007) 986–988

Mao, X.J., Shimai, S., Wang, S.W.: Gelcasting of alumina foams consolidated by epoxy resin. J. Europ. Ceram. Soc. 28 (2008) 217–222

Mazzoni, A.D., Conconi, M.S., Aglietti, E.F.: Phase stability and microstructure of MgAl2O4/SiC composites sintered in argon atmosphere. Ceram. Int. 26 (2000) 147–151

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yuan, L., Yan, Z., Zhang, X. et al. Effects of SiC on the Properties and Microstructures of Closed-Pore Al2O3-MgAl2O4 Refractory Aggregates. Interceram. - Int. Ceram. Rev. 65, 50–53 (2016). https://doi.org/10.1007/BF03401188

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF03401188